- 0086-571-85302990

- sales@greenskybio.com

Only cooperate with the best contract manufacturers of saw palmetto extract.

2024-12-21

Introduction

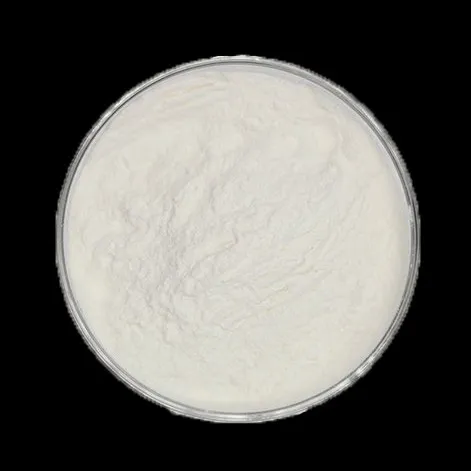

Saw Palmetto Extract has gained significant popularity in recent years due to its numerous potential health benefits. It is widely used in the supplement, pharmaceutical, and cosmetic industries. However, the quality and effectiveness of products containing Saw Palmetto Extract can vary greatly depending on the manufacturing process. This is why it is of utmost importance to only cooperate with the best contract manufacturers of this valuable ingredient.

Quality Control

Raw Material Sourcing

The best contract manufacturers start with high - quality raw materials. They have strict criteria for sourcing saw palmetto berries. These manufacturers ensure that the berries are harvested at the right time and from reliable sources. For example, they may work with suppliers who follow sustainable farming practices. This not only guarantees the quality of the extract but also helps in environmental conservation.

- They carefully select berries that are free from contaminants such as pesticides and heavy metals.

- By choosing the right raw materials, the manufacturers can ensure a consistent and potent extract.

Manufacturing Processes

- Extraction Method: Top contract manufacturers use advanced extraction methods. These methods are designed to preserve the active compounds in the Saw Palmetto Extract. For instance, they may use supercritical fluid extraction, which is known for its efficiency and ability to produce a pure extract without the use of harmful solvents.

- Quality Testing: Throughout the manufacturing process, strict quality testing is carried out. This includes testing for the presence and concentration of key active ingredients. For example, they will measure the levels of fatty acids and sterols, which are important components of saw palmetto extract.

- Batch - to - batch consistency is also monitored. This ensures that each batch of the extract meets the same high - quality standards.

- Microbial testing is another crucial aspect. The extract must be free from harmful bacteria, fungi, and other microorganisms.

- Final Product Packaging: The packaging of the saw palmetto extract is also carefully considered. The best manufacturers use packaging materials that protect the extract from factors such as light, air, and moisture. This helps to maintain the stability and shelf - life of the product.

- Proper labeling is also essential. The label should clearly state the ingredients, dosage instructions, and any potential side effects.

Regulatory Compliance

Meeting Industry Standards

The supplement and pharmaceutical industries are highly regulated. The best contract manufacturers of saw palmetto extract are well - aware of these regulations and ensure full compliance.

- They follow Good Manufacturing Practice (GMP) guidelines. GMP ensures that the manufacturing processes are carried out in a clean, organized, and controlled environment. This helps to prevent contamination and ensure product quality.

- Compliance with regulatory agencies such as the Food and Drug Administration (FDA) in the United States or the European Medicines Agency (EMA) in Europe is crucial. These agencies set strict standards for product safety, efficacy, and labeling.

Documentation and Record - Keeping

- Accurate documentation is a hallmark of the best contract manufacturers. They keep detailed records of every step of the manufacturing process, from raw material sourcing to final product packaging.

- These records are important for traceability. In case of any issues or recalls, the manufacturers can quickly identify the source of the problem and take appropriate action.

- Documentation also helps during regulatory audits. It provides evidence that the manufacturer is following all the necessary regulations.

Innovation Capabilities

Research and Development

The best contract manufacturers invest in research and development (R & D). They are constantly looking for ways to improve the quality and effectiveness of saw palmetto extract.

- They may collaborate with academic institutions or research centers to study the potential health benefits of saw palmetto extract further. This research can lead to new applications for the extract in different industries.

- Through R & D, manufacturers can also develop new extraction methods or product formulations. For example, they may create a more bioavailable form of the extract, which can enhance its absorption in the body.

Adapting to Market Trends

- The market for products containing saw palmetto extract is constantly evolving. The best manufacturers are able to adapt to these changes quickly. They keep an eye on emerging trends such as the demand for natural and organic products.

- They can also respond to changes in consumer preferences. For example, if consumers are increasingly interested in convenient dosage forms like capsules or gummies, the manufacturers can develop products to meet this demand.

Benefits of Cooperating with the Best

Product Reputation

When a company partners with the best contract manufacturers of saw palmetto extract, it can enhance the reputation of its products. High - quality extracts lead to more effective products, which in turn can gain the trust of consumers.

- Positive customer reviews and word - of - mouth recommendations are more likely for products made with top - notch extracts.

- This can help the company build a strong brand image in the highly competitive supplement, pharmaceutical, or cosmetic markets.

Cost - Effectiveness in the Long Run

- Although the services of the best contract manufacturers may seem more expensive initially, they can be cost - effective in the long run. High - quality manufacturing reduces the risk of product recalls, which can be extremely costly.

- Moreover, products made with high - quality saw palmetto extract are more likely to sell well, leading to increased revenue for the company.

Conclusion

In conclusion, when it comes to saw palmetto extract, it is essential to only cooperate with the best contract manufacturers. Their strict quality control, regulatory compliance, and innovation capabilities offer numerous benefits. By partnering with these top - tier manufacturers, companies can ensure the production of high - quality products, enhance their brand reputation, and achieve long - term cost - effectiveness. This ultimately leads to success in the competitive markets where saw palmetto extract - based products are in high demand.

FAQ:

Q1: Why is it important to only cooperate with the best contract manufacturers of saw palmetto extract?

Only working with the best contract manufacturers is crucial because they ensure high - quality production. High - quality saw palmetto extract is essential for the effectiveness of products containing it. The best manufacturers have strict quality control measures in place, which helps to maintain the purity, potency, and consistency of the extract. This, in turn, leads to better - performing products that can meet or exceed consumer expectations.

Q2: What role does quality control play when choosing a contract manufacturer for saw palmetto extract?

Quality control is of utmost importance. A good contract manufacturer will have a comprehensive quality control system. They will test the raw materials for saw palmetto extract to ensure they are of high quality and free from contaminants. During the extraction process, they will monitor parameters such as temperature, pressure, and extraction time to optimize the yield and quality of the extract. After extraction, they will conduct further tests to verify the potency, purity, and stability of the final product, ensuring that only high - quality saw palmetto extract is used in subsequent product formulations.

Q3: How does regulatory compliance factor into choosing the best contract manufacturers of saw palmetto extract?

Regulatory compliance is a key consideration. The best contract manufacturers are well - versed in relevant regulations. They ensure that the production of saw palmetto extract meets all local and international regulatory requirements. This includes compliance with Good Manufacturing Practice (GMP) standards. By adhering to these regulations, they can guarantee the safety and legality of the extract, which is essential for products that will be sold in the market. Non - compliance can lead to product recalls, legal issues, and damage to the brand's reputation.

Q4: What innovation capabilities should the best contract manufacturers of saw palmetto extract possess?

The best contract manufacturers should have strong innovation capabilities. They may be involved in research to develop more efficient extraction methods, which can improve the yield and quality of saw palmetto extract. They could also be innovating in product formulation, finding new ways to incorporate the extract into different types of products. Innovation can give a competitive edge in the market, allowing for the development of unique and high - value products. Additionally, they may be investing in new technologies for quality control and analysis, ensuring the highest standards of the extract are maintained.

Q5: How can one identify the best contract manufacturers of saw palmetto extract?

To identify the best contract manufacturers, one can consider several factors. Firstly, look at their reputation in the industry. A manufacturer with a long - standing positive reputation is likely to be reliable. Check for certifications such as GMP, which indicate compliance with quality and regulatory standards. Examine their production facilities to ensure they are modern, clean, and well - equipped. Also, look at their track record in terms of product quality and customer satisfaction. Another aspect is their research and development capabilities, as innovative manufacturers are more likely to produce high - quality saw palmetto extract.

Related literature

- The Importance of Quality in Saw Palmetto Extract Production"

- "Regulatory Aspects of Saw Palmetto Extract Manufacturing"

- "Innovation in Saw Palmetto Extract Processing: A Review"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Hesperidin

2024-12-21

-

Polygonum multiflorum extract

2024-12-21

-

Beta Carotene

2024-12-21

-

Centella Asiatica Extract

2024-12-21

-

Green Tea Extract

2024-12-21

-

Peppermint Extract Powder

2024-12-21

-

Rose Hip Extract

2024-12-21

-

Beetroot juice Powder

2024-12-21

-

Berberis aristata Extract

2024-12-21

-

Reishi mushroom extract

2024-12-21