- 0086-571-85302990

- sales@greenskybio.com

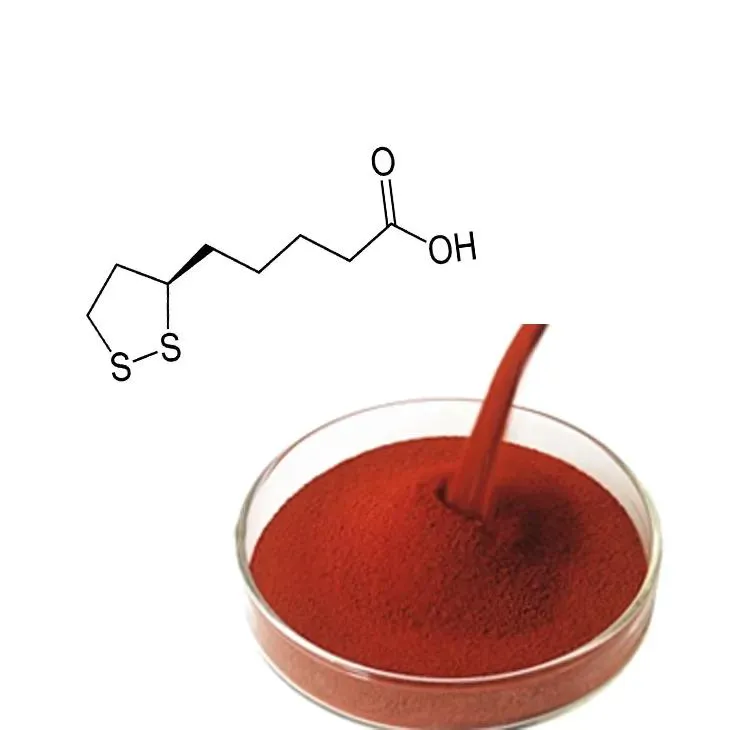

Preparation process of astaxanthin.

2024-12-15

1. Introduction

Astaxanthin is a carotenoid pigment that has attracted significant attention in recent years due to its remarkable antioxidant properties. It is much more potent as an antioxidant compared to other well - known antioxidants such as vitamin C and vitamin E. Astaxanthin is widely used in various industries, including the nutraceutical, cosmetic, and food industries. Given its importance, understanding the preparation processes of Astaxanthin is crucial.

2. Natural Extraction from Haematococcus pluvialis

2.1 Cultivation of Haematococcus pluvialis

Haematococcus pluvialis is one of the most important natural sources of astaxanthin. The cultivation of this microalgae is a complex but essential step in the natural extraction process.

- Nutrient requirements: The right combination of carbon and nitrogen sources is crucial for the growth and astaxanthin production of Haematococcus pluvialis. For example, a balanced supply of nitrate as a nitrogen source and carbon dioxide as a carbon source can promote healthy growth. However, during the astaxanthin - induction phase, a reduction in the nitrogen source while maintaining an appropriate carbon source can stimulate the production of astaxanthin.

- Light and temperature conditions: Light intensity and temperature also play significant roles. Haematococcus pluvialis typically requires a certain amount of light for photosynthesis, but excessive light can cause stress and affect growth. Optimal temperature ranges usually fall between 15 - 25°C, although different strains may have slightly different preferences.

- Cultivation systems: There are different cultivation systems available for Haematococcus pluvialis, such as open - pond systems and closed - photobioreactor systems.

- Open - pond systems are cost - effective but are more vulnerable to contamination from other organisms and environmental fluctuations.

- Closed - photobioreactor systems offer better control over environmental conditions, such as light, temperature, and nutrient supply. However, they are more expensive to set up and operate.

2.2 Harvesting

Once the Haematococcus pluvialis has reached the appropriate growth stage with a sufficient amount of astaxanthin, the next step is harvesting.

- Centrifugation: This is a commonly used method. The microalgae cells are separated from the culture medium by centrifugal force. However, it can be energy - intensive, especially on a large scale.

- Filtration: Filtration can also be used, either through membrane filtration or depth filtration. It is relatively simple but may face challenges such as clogging of the filter if the cell density is high.

2.3 Extraction

After harvesting, the astaxanthin needs to be extracted from the Haematococcus pluvialis cells.

- Organic solvent extraction: Organic solvents such as hexane, acetone, and ethanol are often used. The process involves grinding the harvested cells and then using the solvent to dissolve the astaxanthin. However, the use of organic solvents has some drawbacks, such as potential toxicity and the need for strict safety measures during handling.

- Supercritical fluid extraction: Supercritical carbon dioxide (scCO₂) is an emerging and promising extraction method. It has the advantages of being non - toxic, environmentally friendly, and having a high selectivity for astaxanthin. In this process, the scCO₂ is maintained at a supercritical state (above its critical temperature and pressure), which can effectively extract astaxanthin from the microalgae cells.

2.4 Purification

The extracted astaxanthin often contains impurities, so purification is necessary.

- Column chromatography: This is a widely used purification method. Different types of columns, such as silica gel columns or reverse - phase columns, can be used depending on the nature of the impurities and the properties of astaxanthin. Through the interaction between the astaxanthin and the stationary phase in the column, impurities can be separated from astaxanthin.

- Crystallization: Crystallization can also be employed for purification. By adjusting the temperature, solvent composition, and other factors, astaxanthin can be crystallized out, leaving impurities in the mother liquor.

3. Chemical Synthesis

Chemical synthesis is another approach for the production of astaxanthin.

- Synthetic routes: There are different synthetic routes available. One common method involves the use of chemical precursors and multi - step reactions. For example, starting from simpler organic compounds, through reactions such as condensation and oxidation, astaxanthin can be synthesized. However, these reactions often require strict reaction conditions, including specific temperatures, pressures, and catalysts.

- Purification challenges: Chemical synthesis usually results in a mixture of products, and the purification of astaxanthin is complex. The synthetic astaxanthin may contain isomers or other by - products, which need to be removed to obtain high - quality astaxanthin. This often requires sophisticated purification techniques such as high - performance liquid chromatography (HPLC) to separate astaxanthin from its impurities.

- Advantages and disadvantages: The main advantage of chemical synthesis is its potential for high - volume production, which can meet the large - scale demand in industries. However, the complex synthesis process and purification requirements, as well as potential environmental and safety concerns associated with the use of chemicals, are the main disadvantages.

4. Biotechnology - based Methods

In recent years, biotechnology - based methods for astaxanthin production have been actively explored.

- Recombinant DNA technology in microorganisms: Microorganisms such as bacteria and yeast are being engineered using recombinant DNA technology. Genes responsible for astaxanthin biosynthesis are introduced into these microorganisms, enabling them to produce astaxanthin. For example, certain strains of yeast can be genetically modified to express the necessary enzymes for astaxanthin synthesis.

- Metabolic engineering: This involves modifying the metabolic pathways in the host microorganisms to optimize astaxanthin production. By understanding the metabolic network of the microorganism and manipulating key enzymes and regulatory factors, the yield of astaxanthin can be increased. For instance, enhancing the supply of precursors for astaxanthin synthesis or reducing the flux towards competing metabolic pathways can improve astaxanthin production.

- Challenges and prospects: One of the challenges in biotechnology - based methods is ensuring the stability and expression efficiency of the introduced genes. Also, regulatory approval for genetically modified organisms (GMOs) in different regions can be a hurdle for the commercialization of astaxanthin produced by these methods. However, with continuous research and development, these methods hold great potential for sustainable and efficient astaxanthin production in the future.

5. Conclusion

In conclusion, the preparation of astaxanthin can be achieved through different methods, each with its own advantages and disadvantages. Natural extraction from Haematococcus pluvialis offers a natural and potentially high - quality source of astaxanthin, but it has challenges in cultivation and extraction efficiency. Chemical synthesis can produce large quantities but has complex purification processes. Biotechnology - based methods are emerging and show promise for optimizing production while addressing sustainability concerns. Future research may focus on further improving these methods, especially in terms of increasing yields, reducing costs, and ensuring the safety and quality of astaxanthin for various applications in the nutraceutical, cosmetic, and food industries.

FAQ:

What are the main methods for astaxanthin preparation?

The main methods for astaxanthin preparation include natural extraction from Haematococcus pluvialis, chemical synthesis, and biotechnology - based methods. Natural extraction involves a series of steps from microalgae cultivation to final extraction. Chemical synthesis can produce large volumes but has complex purification processes. Biotechnology - based methods, such as using recombinant DNA technology in microorganisms, are also being explored.

Why is the right combination of carbon and nitrogen sources important in the cultivation of Haematococcus pluvialis for astaxanthin production?

The right combination of carbon and nitrogen sources is crucial for the growth and astaxanthin production of Haematococcus pluvialis. It affects the metabolic processes within the microalgae. A proper balance can optimize the growth conditions, which in turn can enhance the production of astaxanthin.

What are the challenges in the chemical synthesis of astaxanthin?

The challenges in the chemical synthesis of astaxanthin mainly lie in the complex purification processes. The synthesized astaxanthin may contain impurities that need to be removed to ensure its quality. Additionally, the synthesis may require specific reaction conditions and expensive reagents.

How does biotechnology - based method contribute to astaxanthin preparation?

Biotechnology - based methods, like using recombinant DNA technology in microorganisms, contribute to astaxanthin preparation by aiming to optimize production. It can potentially increase the yield of astaxanthin while ensuring its quality and safety. This is important for its applications in various industries such as nutraceutical and cosmetic industries.

What are the applications of astaxanthin in the nutraceutical and cosmetic industries?

In the nutraceutical industry, astaxanthin is used due to its antioxidant properties. It can be used in dietary supplements to provide health benefits. In the cosmetic industry, astaxanthin can be added to skincare products. Its antioxidant properties can help in protecting the skin from damage caused by free radicals, such as reducing wrinkles and improving skin elasticity.

Related literature

- Astaxanthin: Sources, Extraction, Stability, Biological Activities and Its Commercial Applications"

- "Natural Astaxanthin: A Potent Antioxidant for Human Health"

- "Advances in Astaxanthin Production by Microbial Fermentation"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Selenium yeast

2024-12-15

-

Fenugreek Extract Powder

2024-12-15

-

Black Rice Extract

2024-12-15

-

Troxerutin

2024-12-15

-

Soy Extract

2024-12-15

-

Kupilu Extract

2024-12-15

-

Lily extract

2024-12-15

-

Tamarind extract powder

2024-12-15

-

Dan Shen Root Extract/Salvia Root Extract

2024-12-15

-

Epimedium extract powder

2024-12-15