- 0086-571-85302990

- sales@greenskybio.com

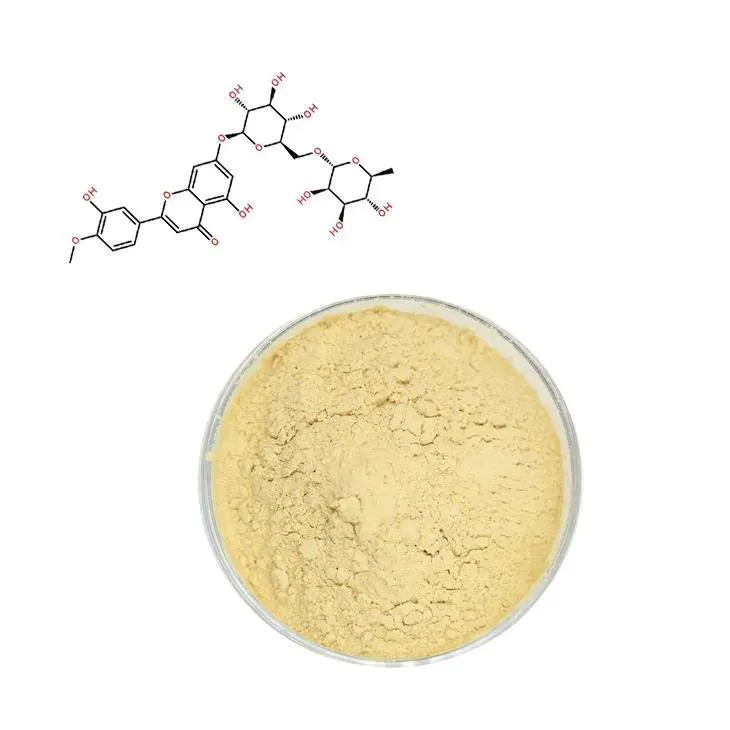

Preparation process of Diosmin.

2024-12-17

1. Introduction

Diosmin, a flavonoid compound of great significance, has been the focus of extensive research due to its various beneficial properties. It plays important roles in the fields of medicine, cosmetics, and food supplements. Understanding the preparation process of Diosmin is crucial for ensuring its quality, purity, and efficacy. This article will provide a comprehensive and detailed exploration of the multi - step process involved in Diosmin preparation.

2. Selection of Raw Materials

The first step in the preparation of Diosmin is the careful selection of raw materials. Raw materials rich in flavonoids are preferred. These can include various plant sources, such as citrus fruits (e.g., oranges, lemons), which are known to be abundant in flavonoid compounds.

- Citrus fruits: They are a common choice because they contain a significant amount of flavonoids including Diosmin. The peel of citrus fruits, in particular, is a rich source. For example, orange peel contains a complex mixture of flavonoids, and Diosmin is one of the important components within this mixture.

- Other plant sources: Some herbs and medicinal plants may also be considered as raw materials. However, their use may be less common compared to citrus fruits. These plants may need to be carefully screened and analyzed to ensure that they contain sufficient levels of Diosmin precursors or Diosmin itself.

3. Extraction Procedures

Once the raw materials are selected, the next step is extraction. The goal of extraction is to isolate the flavonoid - rich fraction from the raw materials. This is often a complex process that involves the use of solvents.

- Solvent Selection: Ethanol is a commonly used solvent for Diosmin extraction. It has several

advantages.

- Ethanol is relatively safe and has a wide range of solubility for flavonoid compounds. It can effectively dissolve Diosmin and other related flavonoids from the plant matrix.

- It is also a solvent that is easy to handle and can be easily removed during the subsequent purification steps. For example, through evaporation, ethanol can be removed, leaving behind the flavonoid - rich extract.

- Extraction Methods: There are different extraction methods that can be employed.

- Maceration is one of the traditional methods. In this method, the raw materials are soaked in the solvent (ethanol) for a certain period of time. This allows the solvent to penetrate the plant material and dissolve the flavonoids. For example, the citrus peel may be cut into small pieces and then soaked in ethanol for several days to weeks, depending on the scale of extraction and the desired yield.

- Another method is Soxhlet extraction. This is a more continuous extraction method. The raw materials are placed in a Soxhlet extractor, and the solvent is continuously recycled through the sample. This method can be more efficient in extracting a higher percentage of Diosmin from the raw materials compared to maceration, especially for larger - scale extraction operations.

4. Purification Step

After extraction, the obtained extract contains not only Diosmin but also other compounds. Therefore, a purification step is necessary to separate and purify Diosmin from these other substances.

- Chromatography Techniques: Chromatography is a powerful tool in the purification of Diosmin.

- High - performance liquid chromatography (HPLC) is widely used. In HPLC, the extract is passed through a column filled with a stationary phase. Different compounds, including Diosmin, will interact differently with the stationary and mobile phases. By carefully adjusting the parameters such as the composition of the mobile phase, flow rate, and column temperature, Diosmin can be separated from other flavonoids and impurities.

- Column chromatography is another option. This method uses a column packed with a suitable adsorbent material. The extract is loaded onto the column, and different compounds are eluted at different times depending on their affinity for the adsorbent. Diosmin can be collected as a pure fraction during the elution process.

- Recrystallization: In some cases, recrystallization can also be used for purification.

- The extract is dissolved in a suitable solvent, and then the solution is allowed to cool slowly. Diosmin, which has a specific solubility profile, will crystallize out of the solution while some impurities remain in the solution. The crystals can be collected and further processed to obtain a purer form of Diosmin.

5. Chemical Modification (if applicable)

In some preparation methods, chemical modification steps may be involved. These steps are aimed at enhancing the purity and bioavailability of Diosmin.

- Esterification: Esterification is one of the possible chemical modifications.

- By reacting Diosmin with certain carboxylic acids, esters of Diosmin can be formed. These esters may have different physical and chemical properties compared to the original Diosmin. For example, they may have improved solubility in certain solvents or better absorption in the body.

- Hydroxylation or other reactions: Depending on the specific requirements and research directions, hydroxylation or other chemical reactions may be carried out on Diosmin. These reactions can introduce new functional groups to Diosmin, which may affect its biological activity, stability, or pharmacokinetic properties.

6. Importance of Parameter Control

Throughout the entire process of Diosmin preparation, strict control of parameters such as temperature, pressure, and reaction time is essential to ensure high - quality Diosmin production.

- Temperature:

- During extraction, the temperature can significantly affect the solubility of Diosmin in the solvent. If the temperature is too low, the extraction efficiency may be reduced as Diosmin may not dissolve well in the solvent. On the other hand, if the temperature is too high, it may lead to the degradation of Diosmin or other flavonoids in the raw materials. For example, when using ethanol extraction, a suitable temperature range (e.g., 40 - 60 °C) may be optimal for most citrus - based raw materials.

- In purification steps such as chromatography, temperature can also influence the separation efficiency. Different compounds may have different temperature - dependent interactions with the stationary and mobile phases. Therefore, maintaining a stable and appropriate temperature is crucial for accurate separation of Diosmin.

- Pressure:

- In some extraction methods like Soxhlet extraction, pressure can play a role. Although Soxhlet extraction is usually carried out at atmospheric pressure, in some cases, modified Soxhlet extractors may be used that can operate under slightly elevated or reduced pressures. These pressure changes can affect the boiling point of the solvent and thus the extraction rate. For example, a slightly reduced pressure can lower the boiling point of ethanol, allowing for a more gentle extraction process that may be beneficial for maintaining the integrity of Diosmin.

- Reaction Time:

- During extraction, the reaction time needs to be carefully controlled. In maceration, if the soaking time is too short, the extraction may be incomplete, and a significant amount of Diosmin may remain in the raw materials. However, if the soaking time is too long, it may not only lead to a waste of time but also may cause the degradation of Diosmin due to prolonged exposure to the solvent. For example, in a typical ethanol maceration of citrus peel, a soaking time of 3 - 7 days may be a reasonable range depending on the thickness of the peel and the extraction conditions.

- In chemical modification steps, the reaction time is also crucial. Insufficient reaction time may result in incomplete modification, while excessive reaction time may lead to unwanted side reactions or over - modification of Diosmin.

7. Conclusion

The preparation process of Diosmin is a complex and multi - step procedure that involves raw material selection, extraction, purification, and potentially chemical modification. Each step requires careful consideration and strict control of various parameters. With the increasing demand for Diosmin in different fields, continuous research and improvement in its preparation process are necessary to ensure high - quality production, which in turn will contribute to its wider application and better utilization of its beneficial properties.

FAQ:

What are the common raw materials for Diosmin preparation?

Common raw materials for Diosmin preparation are those rich in flavonoids. For example, certain plant materials are often used as they naturally contain flavonoid compounds which can be further processed to obtain Diosmin.

Why is ethanol often used in the extraction step?

Ethanol is often used in the extraction step because it is an effective solvent for flavonoids. It has the ability to dissolve the flavonoid - rich fraction from the raw materials, making it possible to isolate the components that can be further processed to obtain Diosmin.

What chromatography techniques are typically used in the purification of Diosmin?

Techniques such as high - performance liquid chromatography (HPLC) are often used in the purification of Diosmin. HPLC can effectively separate Diosmin from other compounds based on their different chemical properties, allowing for a high - purity product.

What are the benefits of chemical modification in Diosmin preparation?

Chemical modification in Diosmin preparation can enhance the purity and bioavailability of Diosmin. It can also improve the stability and solubility of Diosmin, which are important factors for its effectiveness in various applications.

How important is the control of parameters like temperature, pressure and reaction time?

The control of parameters such as temperature, pressure and reaction time is very important. Precise control of these parameters ensures that the chemical reactions occur optimally, leading to high - quality Diosmin production. Incorrect parameters may result in lower yields, reduced purity or even the formation of unwanted by - products.

Related literature

- Optimization of Diosmin Extraction from Plant Sources"

- "Purification and Characterization of Diosmin: A Review"

- "Advances in Chemical Modification of Diosmin for Enhanced Bioavailability"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Andrographis Paniculata Extract Powder

2024-12-17

-

Tormentil Extract

2024-12-17

-

Echinacea Extract

2024-12-17

-

Oat Straw Extract Powder

2024-12-17

-

Gynostemma pentaphyllum extract

2024-12-17

-

Horse Chestnut Extract

2024-12-17

-

Selenium yeast

2024-12-17

-

Rosemary extract

2024-12-17

-

Phellodendron Extract

2024-12-17

-

Stevia Extract

2024-12-17