- 0086-571-85302990

- sales@greenskybio.com

Preparation process of saw palmetto extract.

2024-12-18

1. Introduction

Saw Palmetto Extract has gained significant popularity in recent years due to its potential health benefits. It is widely used in herbal remedies, nutraceuticals, and other related products. The preparation process of Saw Palmetto Extract is a complex and carefully regulated procedure that ensures the final product is of high quality and rich in bioactive compounds.

2. Raw Material Collection: Saw Palmetto Berries

The collection of saw palmetto berries is the first and crucial step in the preparation process.

2.1 Quality Requirements

Only high - quality berries should be selected. High - quality saw palmetto berries are typically those that are fully ripe, free from diseases, and not damaged. These berries are more likely to contain a higher concentration of the desired bioactive compounds.

2.2 Harvesting Time

The timing of harvesting also plays an important role. Harvesting at the right time ensures that the berries have reached their optimal maturity level. For saw palmetto, this usually occurs during a specific season when the berries have developed their full complement of nutrients and bioactive substances.

3. Pre - treatment of Berries

Once the berries are harvested, they need to undergo pre - treatment before extraction.

3.1 Sorting

Sorting is an essential part of the pre - treatment process. The purpose of sorting is to remove any damaged or unripe berries. Damaged berries may introduce contaminants or have a lower content of bioactive compounds. Unripe berries may also lack the full spectrum of beneficial substances. This is usually done by visual inspection or by using mechanical sorting devices that can separate berries based on size, shape, and color.

3.2 Drying

After sorting, the berries are dried. Drying is crucial as it affects the subsequent extraction efficiency. If the berries are not dried properly, excess moisture can lead to issues during extraction, such as reduced extraction yields or the growth of mold and bacteria. There are different methods of drying, including air - drying and using drying machines. The degree of dryness needs to be carefully controlled. Over - drying can also be a problem as it may cause some of the bioactive compounds to degrade. The optimal drying conditions are usually determined based on factors such as the type of drying method, the ambient temperature, and the humidity.

4. Extraction Process

The extraction process is the core of obtaining Saw Palmetto Extract. There are two main types of extraction methods: traditional and modern.

4.1 Traditional Extraction

Traditional extraction often involves cold - pressing the dried berries. This method is relatively simple and has been used for a long time.

- Cold - pressing applies mechanical pressure to the dried berries. This pressure forces out the oils and other bioactive compounds from the berries, resulting in a crude extract.

- However, one of the drawbacks of traditional cold - pressing is that it may not be as efficient in extracting all the desired compounds. Some of the more tightly bound substances may remain in the residue.

4.2 Modern Extraction: Supercritical Fluid Extraction

Modern methods, such as supercritical fluid extraction, are becoming more popular due to their advantages.

- Supercritical fluid extraction uses substances like carbon dioxide under specific pressure and temperature conditions. Carbon dioxide is often chosen because it is non - toxic, non - flammable, and has relatively mild critical conditions.

- Under supercritical conditions, the fluid has properties between those of a gas and a liquid, which allows it to penetrate the matrix of the saw palmetto berries more effectively and selectively extract the bioactive compounds.

- This method offers better selectivity, meaning it can target specific compounds more precisely. It also results in a higher - purity extract compared to traditional methods.

5. Post - extraction Refinement

After the extraction process, the product needs to be refined to obtain the final saw palmetto extract.

5.1 Centrifugation

Centrifugation is often the first step in the refinement process. During centrifugation, the extract is spun at high speeds. This separates the different components based on their density. Heavier particles will sediment at the bottom, while the lighter, desired components remain in the supernatant. This helps to remove impurities such as cell debris and undissolved solids.

5.2 Evaporation

Evaporation is another important step. Evaporation is used to remove any remaining solvents or excess moisture from the extract. This is typically done under controlled conditions to prevent the loss of bioactive compounds. By carefully adjusting the temperature and pressure, the solvent can be evaporated off, leaving behind a more concentrated and pure saw palmetto extract.

6. Final Product and Its Applications

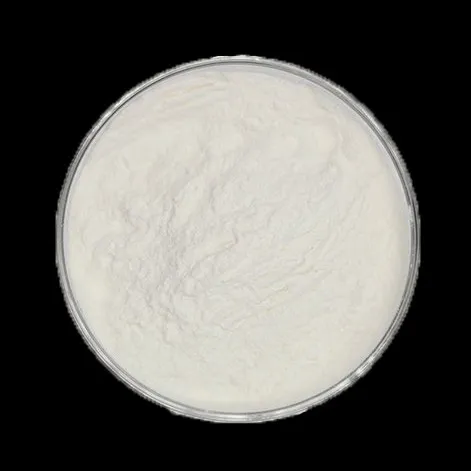

The final saw palmetto extract obtained through this multi - step process is rich in bioactive compounds.

- These bioactive compounds include fatty acids, sterols, and flavonoids, which are believed to have various health - promoting properties.

- The final product is suitable for use in different products. In herbal remedies, it is used to address certain health conditions, such as prostate problems in men. In nutraceuticals, it can be added to dietary supplements to provide potential health benefits.

7. Conclusion

In conclusion, the preparation process of saw palmetto extract is a complex and multi - faceted procedure. From the careful collection of raw materials to the final refinement steps, each stage is crucial in ensuring the quality and effectiveness of the final product. With the increasing demand for natural products with health - promoting properties, the proper preparation of saw palmetto extract becomes even more important.

FAQ:

1. What is the first step in preparing saw palmetto extract?

The first step is the collection of high - quality saw palmetto berries.

2. Why is sorting important during the pre - treatment of saw palmetto berries?

Sorting is important during the pre - treatment because it helps to remove damaged or unripe berries.

3. How does the degree of dryness of the berries affect the extraction?

The degree of dryness affects the subsequent extraction efficiency.

4. What are the differences between traditional and modern extraction methods for saw palmetto extract?

Traditional extraction may involve cold - pressing the dried berries to obtain a crude extract, while modern methods usually rely on supercritical fluid extraction which uses substances like carbon dioxide under specific pressure and temperature conditions, offering better selectivity and purity.

5. What steps are involved in refining the extract after extraction?

After extraction, the product is refined through steps like centrifugation and evaporation.

Related literature

- Saw Palmetto Extract: Composition, Pharmacology, and Clinical Applications"

- "Preparation and Characterization of Saw Palmetto Extracts for Nutraceutical Applications"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Jujube Extract

2024-12-18

-

Camu Camu Extract

2024-12-18

-

Hedyotis Diffusa Extract

2024-12-18

-

Lotus leaf extract

2024-12-18

-

Red Wine Extract

2024-12-18

-

Quercetin

2024-12-18

-

Nutmeg Extract

2024-12-18

-

Saffron Extract Powder

2024-12-18

-

Fenugreek Extract Powder

2024-12-18

-

Alfalfa Meal

2024-12-18