- 0086-571-85302990

- sales@greenskybio.com

Reliability and Efficiency: Pillars for Top Astaxanthin Manufacturers to Provide Effective Products

2024-12-12

1. Introduction

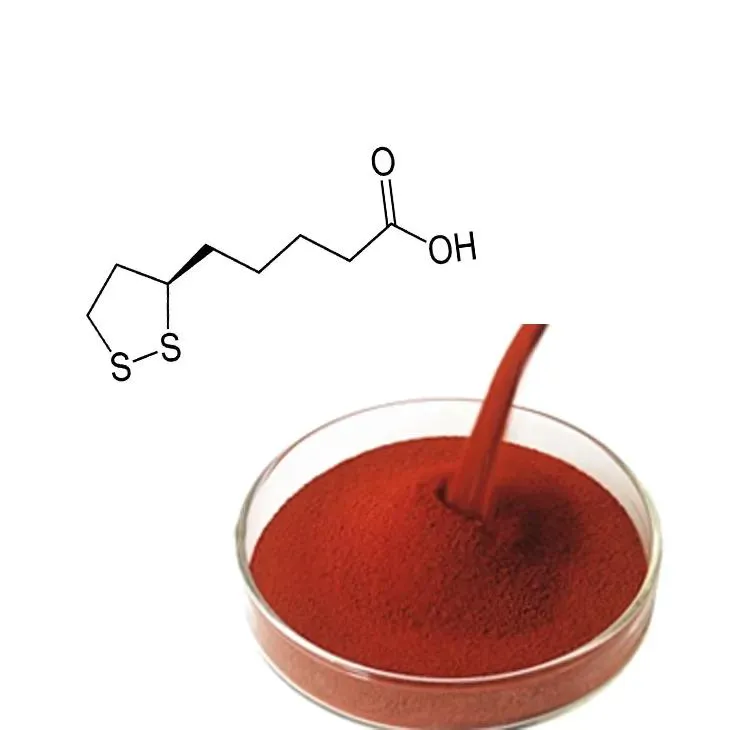

Astaxanthin, a potent antioxidant, has emerged as a highly sought - after compound in recent years. Its numerous health benefits, such as antioxidant, anti - inflammatory, and skin - protecting properties, have led to a growing demand for Astaxanthin - based products. In this competitive market, top - tier Astaxanthin manufacturers distinguish themselves through two fundamental pillars: reliability and efficiency. These two factors play a crucial role in ensuring the production of effective astaxanthin products.

2. The Importance of Reliability

2.1 Quality Control in Raw Material Sourcing

Reliable astaxanthin manufacturers understand the significance of starting with high - quality raw materials. Astaxanthin can be sourced from various organisms, such as microalgae and yeast. Strict quality control in raw material sourcing involves several aspects. First, manufacturers need to ensure that the source organisms are of a high - quality strain. For example, in the case of microalgae - sourced astaxanthin, the selected microalgae strain should have a high astaxanthin content and be free from contaminants.

Second, the growing conditions of the source organisms are crucial. This includes factors such as temperature, light intensity, and nutrient availability. Manufacturers must work with suppliers who maintain optimal growing conditions to ensure the consistency and quality of the astaxanthin produced by these organisms. Additionally, traceability of raw materials is essential. This allows manufacturers to track the origin of the raw materials, which is important for quality assurance and in case of any potential recalls.

2.2 Manufacturing Process Reliability

Once the raw materials are sourced, the manufacturing process itself must be highly reliable. This process typically involves extraction, purification, and formulation steps. In the extraction phase, different methods can be used, such as solvent extraction or supercritical fluid extraction. Reliable manufacturers will choose the most appropriate extraction method based on factors such as the nature of the raw material and the desired purity of the astaxanthin product.

During purification, any impurities, including other pigments or unwanted substances, need to be removed. This requires precise control of purification processes, such as chromatography techniques. The formulation step is also critical, as it determines the final form of the astaxanthin product, whether it is in the form of capsules, tablets, or liquid suspensions. Manufacturers must ensure that the formulation is stable and that the astaxanthin remains effective throughout its shelf - life.

2.3 Packaging and Quality Assurance

The final stage of the manufacturing process, packaging, also plays a vital role in reliability. Packaging should protect the astaxanthin product from environmental factors such as light, moisture, and oxygen, which can degrade the astaxanthin. High - quality, light - resistant, and air - tight packaging materials are often used.

In addition to packaging, quality assurance testing is carried out at multiple stages of the manufacturing process. This includes tests for purity, potency, and stability of the astaxanthin product. Only products that pass these stringent quality tests are released to the market. By maintaining high - quality standards throughout the entire manufacturing process, from raw material sourcing to final product packaging, reliable manufacturers can ensure the effectiveness of their astaxanthin products.

3. The Significance of Efficiency

3.1 Timely Market Delivery

Efficiency in production is essential for astaxanthin manufacturers to meet the market demand in a timely manner. In a fast - paced market, where consumer demand for health - enhancing products is constantly growing, manufacturers need to be able to quickly produce and supply astaxanthin products. This requires streamlined production processes that minimize bottlenecks and delays.

For example, efficient supply chain management is crucial. Manufacturers need to have reliable suppliers of raw materials who can deliver on time. At the same time, internal production processes should be optimized to reduce production time without sacrificing quality. By ensuring timely market delivery, manufacturers can take advantage of market opportunities and gain a competitive edge.

3.2 Cost - Effectiveness

Efficiency also leads to cost - effectiveness in astaxanthin production. By optimizing production processes, manufacturers can reduce waste, lower energy consumption, and make more efficient use of resources. For instance, in the extraction process, an efficient extraction method can extract a higher yield of astaxanthin from the raw materials, reducing the amount of raw material required per unit of product.

This not only reduces production costs but also has environmental benefits. Cost - effective production allows manufacturers to offer their astaxanthin products at competitive prices, which is important in a market where price is often a factor in consumer choice. Moreover, cost - savings can be reinvested in research and development to further improve product quality and effectiveness.

4. The Link between Reliability, Efficiency, and Research and Development

Manufacturers known for their reliability are more likely to invest in research and development (R & D). Reliability implies a long - term commitment to quality, which often goes hand - in - hand with a desire to improve products through R & D. These manufacturers recognize that continuous innovation is necessary to stay competitive in the astaxanthin market.

R & D efforts can lead to more effective astaxanthin products in several ways. First, research can focus on improving the extraction and purification methods to increase the purity and potency of astaxanthin. Second, studies can be carried out on new formulations to enhance the bioavailability of astaxanthin in the human body. For example, developing novel delivery systems that can improve the absorption of astaxanthin in the gut.

Efficiency also supports R & D. Cost - savings achieved through efficient production can be redirected towards R & D activities. Additionally, an efficient production process can provide a stable base for R & D, as it allows for more predictable production volumes and timelines. This enables researchers to better plan and conduct experiments related to product improvement.

5. Case Studies of Successful Astaxanthin Manufacturers

There are several examples of astaxanthin manufacturers that have thrived due to their emphasis on reliability and efficiency. One such company is AstaReal, which has been a pioneer in astaxanthin production. AstaReal has a highly reliable raw material sourcing process, relying on its own microalgae farms to ensure the quality and traceability of the astaxanthin - producing microalgae.

Their manufacturing process is also characterized by strict quality control at every stage. In terms of efficiency, AstaReal has continuously optimized its production processes, enabling it to meet the growing global demand for astaxanthin products in a timely manner. Another example is BASF, a large chemical company that has entered the astaxanthin market. BASF's reputation for reliability in chemical manufacturing has translated well into its astaxanthin production.

They have invested in advanced research and development to improve the quality and effectiveness of their astaxanthin products. Their efficient production processes also allow them to be competitive in terms of cost and market delivery. These case studies illustrate how reliability and efficiency can contribute to the success of astaxanthin manufacturers.

6. Conclusion

In conclusion, reliability and efficiency are indeed the cornerstones for top - tier astaxanthin manufacturers in providing effective products. Reliability ensures that the astaxanthin products are of high quality, from raw material sourcing to final packaging. This includes strict quality control in all aspects of the manufacturing process and comprehensive quality assurance testing.

Efficiency, on the other hand, enables manufacturers to meet market demand in a timely manner and in a cost - effective way. The link between reliability, efficiency, and research and development further enhances the quality and effectiveness of astaxanthin products. Manufacturers that can master these two factors, as demonstrated by successful case studies, are well - positioned to succeed in the competitive astaxanthin market and continue to provide consumers with high - quality, effective astaxanthin - based products.

FAQ:

1. What are the key aspects of reliable manufacturing processes for astaxanthin?

Reliable manufacturing processes for astaxanthin include strict quality control at every stage. This starts with sourcing high - quality raw materials, ensuring proper extraction methods, accurate purification processes, and proper formulation. During production, factors such as maintaining appropriate temperature, pressure, and reaction times are crucial. Also, strict quality checks during and after production, as well as proper packaging to protect the product from degradation, are important aspects of reliable manufacturing.

2. How does efficiency in production affect the quality of astaxanthin products?

Efficiency in production does not mean sacrificing quality. Instead, it ensures that the astaxanthin product reaches the market in a timely manner while still maintaining high quality. By optimizing production processes, manufacturers can reduce the time between raw material acquisition and final product distribution. This is achieved through streamlined production lines, advanced manufacturing techniques, and proper scheduling. For example, efficient extraction methods can preserve the antioxidant properties of astaxanthin better, and timely packaging can prevent exposure to factors that might degrade it.

3. Why is research and development important for reliable astaxanthin manufacturers?

Research and development (R & D) is crucial for reliable astaxanthin manufacturers. Firstly, R & D helps in improving the manufacturing processes to enhance product quality and reliability. It can lead to the discovery of more efficient extraction methods, better purification techniques, and improved formulations. Secondly, R & D allows manufacturers to explore new applications of astaxanthin, which can expand their market reach. It also helps in staying ahead of competitors by continuously innovating and providing more effective products.

4. How can consumers identify reliable astaxanthin manufacturers?

Consumers can identify reliable astaxanthin manufacturers in several ways. One way is to look for manufacturers with proper certifications, such as Good Manufacturing Practice (GMP) certifications. These certifications indicate that the manufacturer follows strict quality and safety standards. Another way is to check for customer reviews and testimonials. Positive feedback from other consumers can be a good indication of a reliable manufacturer. Additionally, manufacturers who are transparent about their production processes, including raw material sourcing and quality control measures, are more likely to be reliable.

5. What role does quality control play in the manufacturing of astaxanthin?

Quality control plays a vital role in the manufacturing of astaxanthin. It starts with the inspection of raw materials to ensure they meet the required standards. During production, quality control monitors various parameters such as purity, potency, and stability. After production, final product testing is done to ensure that the astaxanthin product is safe, effective, and meets all regulatory requirements. Quality control helps to identify and correct any potential issues at each stage of production, thus ensuring a high - quality final product.

Related literature

- The Role of Astaxanthin in Health and Wellness"

- "Manufacturing Processes of Antioxidants: A Focus on Astaxanthin"

- "Quality Assurance in Astaxanthin Production: Best Practices"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Nettle leaf extract

2024-12-12

-

Genistein

2024-12-12

-

White mustard seed extract

2024-12-12

-

Grapefruit Seed Extract Powder

2024-12-12

-

Plantain extract

2024-12-12

-

Sea buckthorn oil

2024-12-12

-

Mangosteen extract powder

2024-12-12

-

Red Vine Extract

2024-12-12

-

Purple Sweet Potato Extract

2024-12-12

-

Polygonum multiflorum extract

2024-12-12