- 0086-571-85302990

- sales@greenskybio.com

Understand the main processes of astaxanthin manufacturing in the food industry.

2024-12-21

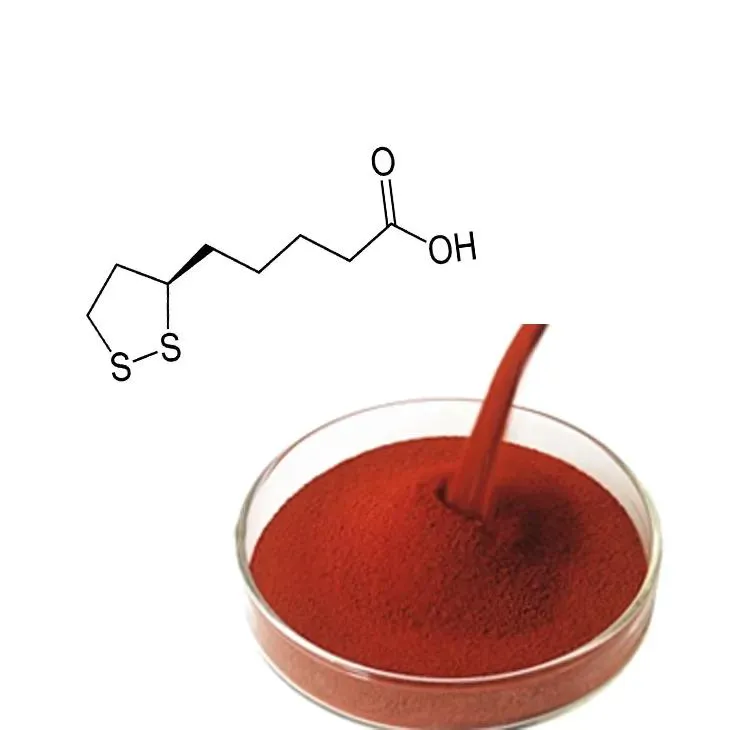

1. Introduction to Astaxanthin

Astaxanthin is a carotenoid pigment with remarkable antioxidant properties. It has gained significant attention in the food industry due to its potential health benefits and its use as a natural colorant. In the context of food manufacturing, Astaxanthin can be sourced from different methods, each with its own set of processes.

2. Production from Microalgae

2.1 Strain Selection

Strain selection is a crucial first step in astaxanthin production from microalgae. Microalgae are a diverse group of photosynthetic organisms, and certain strains are more suitable for astaxanthin production. For example, some Chlorophyceae species have shown great potential. These strains are carefully chosen based on their genetic makeup and their ability to accumulate astaxanthin. Scientists look for strains that can efficiently convert sunlight, carbon dioxide, and nutrients into astaxanthin under specific conditions.

2.2 Cultivation Conditions

Once the appropriate strains are selected, they need to be cultured in an optimized environment. Several factors play a vital role in this process:

- Salinity: The right salinity level is essential for the growth and astaxanthin production of microalgae. Different microalgae strains may have different salinity requirements. For example, some may thrive in brackish water with a specific salt concentration, while others may prefer more or less saline conditions.

- pH: Maintaining the correct pH is also crucial. Microalgae growth and astaxanthin synthesis can be significantly affected by pH. Most microalgae grow well within a certain pH range, typically between 7 and 9. Deviations from this range can lead to reduced growth rates and lower astaxanthin production.

- Carbon Dioxide Levels: As photosynthetic organisms, microalgae require carbon dioxide for growth. Adequate carbon dioxide supply is necessary for efficient photosynthesis and subsequent astaxanthin accumulation. However, too much or too little carbon dioxide can have negative impacts. In a controlled cultivation environment, the carbon dioxide levels are carefully regulated to optimize microalgae growth and astaxanthin production.

2.3 Astaxanthin Accumulation under Stress Conditions

Interestingly, microalgae tend to accumulate astaxanthin especially under stress conditions.

- High Light Intensity: When exposed to high light intensity, microalgae may experience stress. To protect themselves from the potential damage caused by excessive light, they start to produce and accumulate astaxanthin. Astaxanthin acts as a natural antioxidant, scavenging free radicals generated during photosynthesis and protecting the microalgae cells from oxidative stress.

- Nutrient Deficiency: Another stress factor is nutrient deficiency. When microalgae lack certain essential nutrients such as nitrogen or phosphorus, they initiate a series of physiological responses, one of which is the increased production of astaxanthin. This is thought to be a survival mechanism, as astaxanthin can help the microalgae endure the harsh conditions until the nutrient supply is restored.

2.4 Harvesting

After the microalgae have grown and accumulated astaxanthin, they need to be harvested. Harvesting is a critical step as it determines the efficiency of the overall production process. One common method is centrifugation. In this process, the microalgae culture is spun at high speeds in a centrifuge. Due to the difference in density between the microalgae cells and the surrounding medium, the microalgae cells are separated and collected at the bottom of the centrifuge tube. Other harvesting methods may also be used, depending on the scale of production and the characteristics of the microalgae strains.

2.5 Extraction

Once the microalgae are harvested, the next step is to extract astaxanthin from the microalgae biomass. This process typically involves two main steps:

- Mechanical Disruption: The first step is to break open the microalgae cells to release the astaxanthin. This can be achieved through various mechanical means such as high - pressure homogenization or bead milling. Mechanical disruption helps to expose the astaxanthin, which is usually located within the cells, to the extraction solvent in the next step.

- Solvent Extraction: After mechanical disruption, a suitable solvent is used to extract astaxanthin from the disrupted microalgae biomass. Commonly used solvents include hexane, ethanol, or a combination of both. The choice of solvent depends on factors such as the solubility of astaxanthin, the selectivity of the solvent towards astaxanthin, and the safety and environmental considerations in the food industry. The solvent extraction process is carefully controlled to ensure high extraction efficiency and purity of the astaxanthin product.

3. Chemical Synthesis of Astaxanthin

Chemical synthesis is another method for producing astaxanthin. In this approach, raw materials are reacted in a series of chemical reactions in a controlled laboratory environment. However, this method has some drawbacks, especially in the food industry.

- One of the main concerns is safety. Chemical synthesis may involve the use of chemicals that could potentially leave residues in the final product. These residues may pose risks to human health, which is a significant consideration in the food industry where safety is of utmost importance.

- Despite the fact that chemical synthesis can produce astaxanthin on a large scale, the product is often considered less 'natural' compared to astaxanthin sourced from natural organisms such as microalgae. As consumers are increasingly demanding natural products, the market preference for chemically synthesized astaxanthin in the food industry is relatively low.

4. Market Preference for Natural - Source - Derived Astaxanthin

In the food industry, there is a growing preference for astaxanthin derived from natural sources, whether it is from microalgae or other natural organisms.

- One of the main reasons is the perception of naturalness. Consumers tend to believe that natural - source - derived astaxanthin is more 'pure' and less likely to have unwanted additives or contaminants. This perception is driven by the general trend towards consuming more natural and healthy foods.

- Another factor is the potential health benefits. Natural - source - derived astaxanthin is often associated with a range of health benefits, such as antioxidant, anti - inflammatory, and cardiovascular protection properties. These health claims are further supported by some scientific studies, which make natural - source - derived astaxanthin more appealing to consumers and food manufacturers alike.

5. Conclusion

In conclusion, the production of astaxanthin in the food industry involves different processes depending on the source. Production from microalgae is a complex but promising method, with each step from strain selection to extraction being carefully controlled. While chemical synthesis is also an option, it is less favored in the food industry due to safety concerns. The market preference for natural - source - derived astaxanthin is on the rise, driven by consumer demand for natural and healthy products. Understanding these main processes is essential for food manufacturers looking to incorporate astaxanthin into their products in a safe and efficient manner.

FAQ:

What are the main sources of astaxanthin in the food industry?

The main sources of astaxanthin in the food industry are microalgae and chemical synthesis. However, due to potential safety concerns, natural - source - derived astaxanthin from microalgae or other natural organisms is more in demand for food applications.

Why is the selection of microalgae strains important in astaxanthin production?

The selection of suitable microalgae strains is important because different strains may have different capabilities to accumulate astaxanthin. For example, some Chlorophyceae species are selected as they can effectively produce astaxanthin when cultured in the right environment.

What environmental factors need to be optimized for microalgae growth in astaxanthin production?

For microalgae growth in astaxanthin production, factors such as salinity, pH, and carbon dioxide levels need to be optimized. These factors create an environment conducive to the growth of microalgae and their astaxanthin accumulation.

How is microalgae harvested in astaxanthin production?

In astaxanthin production, techniques such as centrifugation are used to harvest microalgae. This helps to collect the microalgae biomass for further extraction of astaxanthin.

What are the steps involved in extracting astaxanthin from microalgae?

The extraction of astaxanthin from microalgae may involve mechanical disruption followed by solvent extraction. This helps to isolate astaxanthin from the harvested microalgae biomass.

Related literature

- Astaxanthin Production from Microalgae: A Review of Cultivation, Harvesting, and Extraction"

- "Natural Astaxanthin: Sources, Production, and Applications in the Food Industry"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Pine bark Extract Powder

2024-12-21

-

Acerola Juice Powder

2024-12-21

-

Green Tea Extract

2024-12-21

-

Lavender Extract

2024-12-21

-

Hedyotis Diffusa Extract

2024-12-21

-

Passionflower Extract

2024-12-21

-

White Peony Extract

2024-12-21

-

Cocoa Extract

2024-12-21

-

Mango flavored powder

2024-12-21

-

Sea buckthorn oil

2024-12-21