- 0086-571-85302990

- sales@greenskybio.com

Understand the main processes of eucommia ulmoides extract manufacturing in the food industry.

2024-12-14

1. Introduction

In the modern food industry, there is an increasing demand for natural and functional ingredients. Eucommia ulmoides extract has emerged as a valuable substance due to its potential health benefits. This article aims to explore the main processes involved in the manufacturing of Eucommia Ulmoides Extract in the food industry.

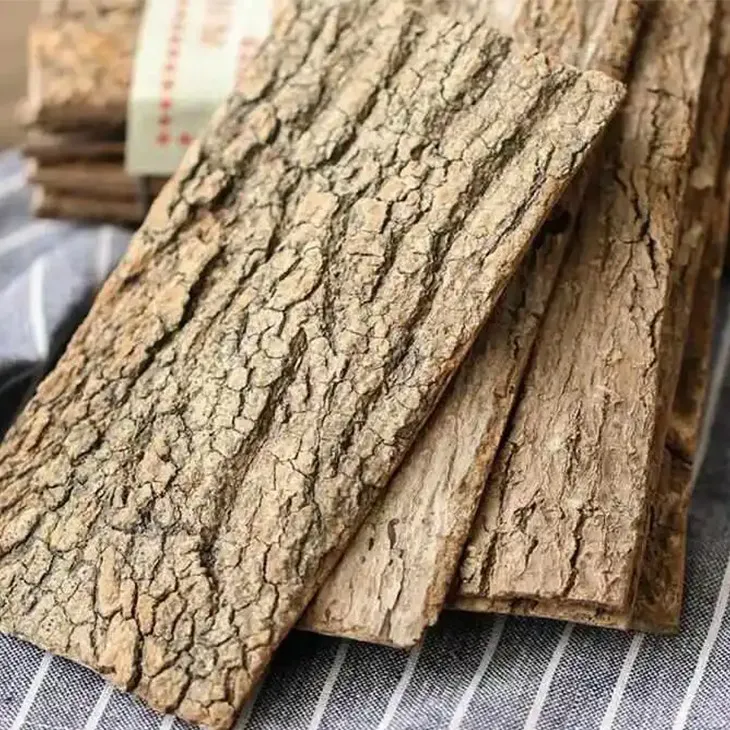

2. Raw Material Collection

High - quality raw materials are the foundation of good Eucommia Ulmoides Extract.

- The collection process is crucial. It involves sourcing Eucommia ulmoides from reliable areas.

- Collectors need to ensure that the plants are grown in suitable environmental conditions, such as proper soil, sunlight, and water availability.

- Only mature Eucommia ulmoides plants are usually selected, as they are more likely to contain higher levels of active components.

3. Pretreatment of Raw Materials

Once the raw materials are collected, they undergo a series of pretreatment processes.

3.1 Cleaning

- The first step in pretreatment is cleaning. Eucommia ulmoides plants may carry dirt, dust, and other impurities.

- Cleaning can be done using water. Gentle washing methods are preferred to avoid damaging the plant tissues.

3.2 Drying

- After cleaning, drying is necessary. Drying helps to remove moisture from the raw materials.

- There are different drying methods, such as natural drying and artificial drying. Natural drying may take longer but can preserve the natural properties of the plants better in some cases. Artificial drying, on the other hand, can be more efficient and can be controlled better in terms of temperature and humidity.

3.3 Crushing

- The dried Eucommia ulmoides needs to be crushed into smaller particles. Crushing makes it easier for the subsequent extraction process.

- Appropriate crushing equipment is used to ensure that the particles are of a suitable size. Too large particles may lead to incomplete extraction, while too small particles may cause problems during filtration and other processes.

4. Extraction

Extraction is a key step in obtaining the active components from Eucommia ulmoides.

4.1 Solvent Extraction

- One of the most common extraction methods is solvent extraction. Appropriate solvents are selected based on the solubility of the active components in Eucommia ulmoides.

- For example, ethanol is often used as a solvent. Ethanol has good solubility for many active components in Eucommia ulmoides and is also relatively safe in the food industry.

- The crushed Eucommia ulmoides is mixed with the solvent in a certain proportion. This mixture is then stirred or agitated to ensure good contact between the solvent and the plant material, facilitating the extraction process.

4.2 Other Extraction Methods

- In addition to solvent extraction, there are other extraction methods that can be considered. For instance, supercritical fluid extraction.

- Supercritical fluid extraction uses a supercritical fluid, such as supercritical carbon dioxide. This method has some advantages, such as being more environmentally friendly and having better selectivity for certain active components.

- However, supercritical fluid extraction may require more complex equipment and higher costs compared to solvent extraction, so it is not as widely used in the manufacturing of Eucommia Ulmoides Extract at present.

5. Purification

After extraction, the extract contains not only the desired active components but also impurities. Purification is required to obtain a high - quality Eucommia ulmoides extract.

5.1 Filtration

- Filtration is a simple and commonly used purification method. It can remove large particles and insoluble substances from the extract.

- Different types of filters can be used, such as filter papers or membrane filters. The choice of filter depends on the nature of the extract and the size of the impurities to be removed.

5.2 Chromatography

- Chromatography is a more advanced purification method. It can separate different components in the extract based on their different affinities for the stationary and mobile phases.

- There are various types of chromatography, such as column chromatography, thin - layer chromatography, and high - performance liquid chromatography (HPLC). HPLC is often used in the purification of Eucommia ulmoides extract due to its high separation efficiency and accuracy.

6. Concentration and Drying

After purification, the Eucommia ulmoides extract needs to be concentrated and dried to obtain the final product with a certain specification.

6.1 Concentration

- Concentration is the process of reducing the volume of the extract while increasing the concentration of the active components. This can be achieved through evaporation, for example.

- Evaporation can be carried out under reduced pressure to lower the boiling point of the solvent and avoid excessive heat damage to the active components.

6.2 Drying

- After concentration, drying is carried out to remove the remaining solvent completely. Drying methods include spray drying, freeze - drying, etc.

- Spray drying is a relatively fast drying method. It can transform the liquid extract into a powder form quickly. Freeze - drying, on the other hand, can better preserve the structure and activity of the active components, but it is more expensive and time - consuming.

7. Conclusion

The manufacturing process of Eucommia ulmoides extract in the food industry involves multiple steps, from raw material collection to final product formation. Each step plays an important role in ensuring the quality and functionality of the extract. With the continuous development of the food industry, further research and improvement on the manufacturing process of Eucommia ulmoides extract are expected to meet the increasing demand for natural and functional ingredients.

FAQ:

1. What are the key factors in selecting high - quality Eucommia ulmoides raw materials?

The key factors in selecting high - quality Eucommia ulmoides raw materials include factors such as the origin of the plant. Eucommia ulmoides from areas with suitable climate and soil conditions are often of better quality. Also, the growth stage of the plant matters. Mature plants usually contain more active components. Additionally, the appearance of the raw materials should be inspected to ensure there is no obvious damage or disease, which can affect the purity and effectiveness of the final extract.

2. Why is pretreatment necessary for Eucommia ulmoides raw materials?

Pretreatment is necessary for Eucommia ulmoides raw materials. Cleaning is done to remove dirt, debris, and other contaminants that may be present on the surface of the raw materials. Drying helps to reduce the moisture content, preventing the growth of microorganisms and spoilage during subsequent processes. Crushing is carried out to increase the surface area of the raw materials, which is beneficial for the extraction process as it allows the solvent to better access the active components within the Eucommia ulmoides.

3. What are the common solvents used in the solvent extraction of Eucommia ulmoides?

Common solvents used in the solvent extraction of Eucommia ulmoides include ethanol. Ethanol is a popular choice because it is relatively safe, can effectively dissolve many of the active components in Eucommia ulmoides, and is also easy to remove during the subsequent purification and concentration processes. Another solvent that may be used in some cases is water, especially when extracting water - soluble components.

4. How does filtration help in purifying the Eucommia ulmoides extract?

Filtration helps in purifying the Eucommia ulmoides extract by removing solid impurities. It allows the liquid extract to pass through a filter medium while trapping particles such as unextracted plant debris, dust, or insoluble substances formed during the extraction process. This results in a cleaner extract, which is important for obtaining a high - quality final product.

5. What are the advantages of chromatography in the purification of Eucommia ulmoides extract?

Chromatography has several advantages in the purification of Eucommia ulmoides extract. It can separate different components based on their chemical properties such as polarity or molecular size. This allows for the isolation of the desired active components from other substances in the extract more precisely. It can also help in removing impurities that are difficult to separate by other methods, thus improving the purity and quality of the final Eucommia ulmoides extract.

Related literature

TAGS:- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Grapefruit Seed Extract Powder

2024-12-14

-

Pomegranate Extract

2024-12-14

-

Maitake Mushroom Extract

2024-12-14

-

Curcumin

2024-12-14

-

Gynostemma pentaphyllum extract

2024-12-14

-

Licorice Root Extract Powder

2024-12-14

-

Cat Claw Extract

2024-12-14

-

Hawthorn powder

2024-12-14

-

Europen Bilberry Extract

2024-12-14

-

Garcinia Cambogia Extract

2024-12-14