- 0086-571-85302990

- sales@greenskybio.com

Understand the main processes of resveratrol extract manufacturing in the food industry.

2024-12-16

1. Introduction

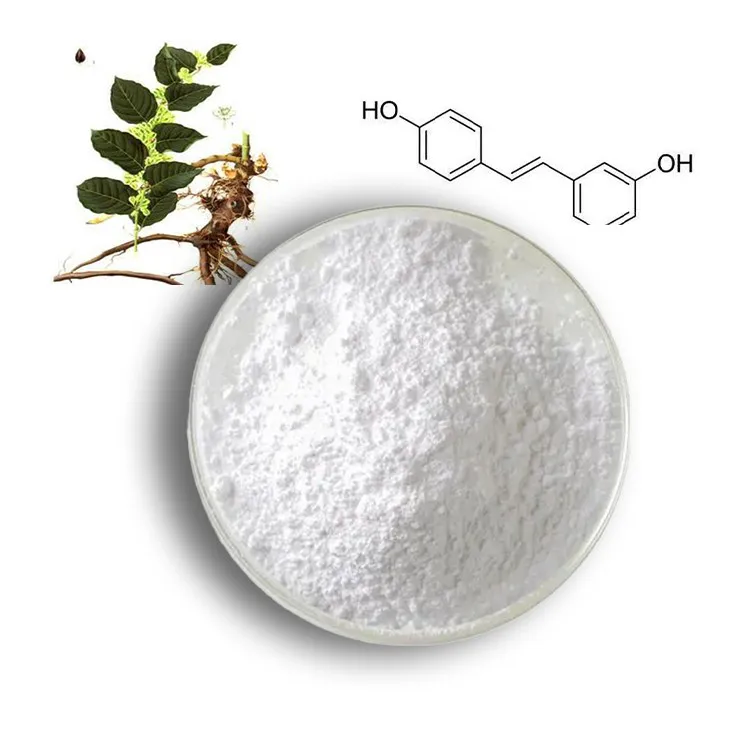

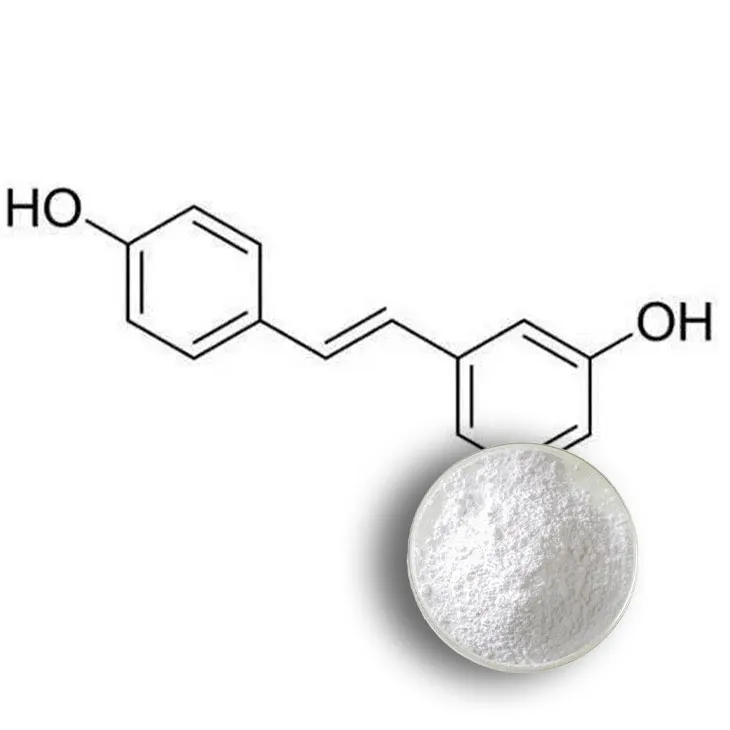

Resveratrol is a compound that has gained significant attention in the food industry due to its potential health benefits. It is found in various plant sources and is often extracted for use in food products such as fortified beverages and health - promoting snacks. The manufacturing process of white Resveratrol extract is complex and involves several key steps.

2. Sourcing of Plant - Based Materials

The first step in the manufacturing of Resveratrol extract is the sourcing of suitable plant - based materials. Resveratrol is naturally present in certain plants, and the choice of these plants is crucial for a successful extraction process.

2.1 Berries

Many types of berries are rich sources of resveratrol. For example, grapes, especially the skins of red grapes, contain a notable amount of resveratrol. The polyphenolic compound is synthesized in the grapevine as a response to various stresses such as fungal infections. During the winemaking process, resveratrol can be transferred from the grape skins to the wine, but for the purpose of Resveratrol extract manufacturing, the grape skins themselves can be used as a starting material. Another berry that contains resveratrol is the blueberry. Blueberries are known for their high antioxidant content, and resveratrol is one of the antioxidants present in them.

2.2 Medicinal Plants

Some medicinal plants also contain resveratrol. For instance, Japanese knotweed (Polygonum cuspidatum) is a well - known source of resveratrol. This plant has been used in traditional medicine in some Asian countries, and it contains a relatively high concentration of resveratrol compared to other plants. However, when using medicinal plants as a source, it is important to ensure that the extraction process is carried out in a way that meets all regulatory requirements, especially considering the potential for other bioactive compounds in the plant to interact with resveratrol or have their own effects on the final product.

3. Extraction Phase

Once the plant - based materials are sourced, the next step is the extraction of resveratrol. There are different techniques available for this purpose, with maceration and Soxhlet extraction being two commonly used methods.

3.1 Maceration

Maceration is a relatively simple extraction method. In this process, the plant material is soaked in a solvent for a period of time. The solvent is chosen based on its ability to dissolve resveratrol effectively. Common solvents used in maceration for resveratrol extraction include ethanol and methanol. The plant material is finely ground or chopped before being placed in the solvent. This increases the surface area of the plant material exposed to the solvent, allowing for more efficient extraction. The mixture is then left to stand for a certain period, which can range from a few hours to several days. During this time, resveratrol gradually dissolves in the solvent. However, one of the drawbacks of maceration is that it can be a relatively slow process, and the extraction efficiency may not be as high as some other methods.

3.2 Soxhlet Extraction

Soxhlet extraction is a more continuous and efficient method compared to maceration. In this technique, the plant material is placed in a Soxhlet extractor, which is a specialized piece of laboratory equipment. The solvent is continuously recycled through the plant material in the extractor. The solvent vaporizes in a distillation flask, rises through a condenser, and then drips back onto the plant material. This continuous cycle allows for a more thorough extraction of resveratrol. Soxhlet extraction can be more time - efficient as it can extract a significant amount of resveratrol in a relatively shorter period compared to maceration. However, it also requires more complex equipment and careful control of the extraction conditions such as temperature and solvent flow rate.

4. Refining the Extract

After the extraction process, the resulting extract contains not only resveratrol but also other impurities. Therefore, it is necessary to refine the extract to obtain a purer form of resveratrol.

4.1 Filtration

Filtration is the first step in refining the extract. The extract is passed through a filter medium, which can be a filter paper, a membrane filter, or a filter cartridge. The filter medium has pores of a certain size that allow the liquid part of the extract (containing resveratrol) to pass through while retaining larger particles such as plant debris, undissolved solids, and some large - molecular - weight impurities. There are different types of filtration methods, such as gravity filtration and vacuum filtration. Gravity filtration is a simple method where the extract is poured through the filter under the force of gravity. Vacuum filtration, on the other hand, uses a vacuum pump to draw the extract through the filter more quickly, which can be useful when dealing with larger volumes of extract or when a faster filtration rate is desired.

4.2 Centrifugation

Centrifugation is another important step in refining the extract. In this process, the extract is placed in a centrifuge tube and spun at a high speed. The centrifugal force causes the denser particles in the extract to move towards the bottom of the tube, while the supernatant (the liquid part containing resveratrol) can be separated. Centrifugation is effective in removing smaller particles and some emulsified impurities that may not be removed by filtration alone. By combining filtration and centrifugation, a relatively pure resveratrol extract can be obtained, which is then ready for the final preparation steps.

5. Final Preparation of Resveratrol Extract

After refining, the resveratrol extract needs to be prepared in a form that is suitable for use in food products. There are two main methods for this final preparation: crystallization and freeze - drying.

5.1 Crystallization

Crystallization is a process that involves the formation of crystals of resveratrol from the purified extract. This is achieved by carefully controlling the concentration of resveratrol in the solution, as well as other factors such as temperature and the presence of seed crystals. The extract is first concentrated to a point where the resveratrol is close to its saturation point in the solvent. Then, by slowly changing the conditions such as cooling the solution or adding a small amount of seed crystals (tiny crystals of resveratrol to initiate the crystallization process), resveratrol crystals start to form. The crystals can then be separated from the remaining liquid by filtration or centrifugation. Crystallized resveratrol has a more stable form and can be easily incorporated into food products such as powdered supplements or fortified foods.

5.2 Freeze - Drying

Freeze - drying, also known as lyophilization, is another method for preparing the resveratrol extract. In this process, the refined extract is first frozen. Then, under a vacuum, the ice in the frozen extract is sublimated (directly converted from a solid to a gas without passing through the liquid phase). This results in a dry powder form of the resveratrol extract. Freeze - drying is advantageous as it helps to preserve the bioactivity of resveratrol as the process is carried out at low temperatures and in a low - oxygen environment. The resulting freeze - dried resveratrol extract can be used in a variety of food products, such as in the production of health - promoting snacks where it can be added as a dry ingredient.

6. Conclusion

The manufacturing process of resveratrol extract in the food industry is a multi - step process that involves careful sourcing of plant - based materials, efficient extraction techniques, refining of the extract, and final preparation methods. Each step is crucial in ensuring the production of a high - quality resveratrol extract that can be safely and effectively used in food products. With the increasing demand for functional foods containing bioactive compounds like resveratrol, understanding these manufacturing processes becomes even more important for both producers and consumers.

FAQ:

What are the common plant - based materials used for resveratrol extraction?

Some types of berries and certain medicinal plants are common plant - based materials used for resveratrol extraction as they are known to contain resveratrol.

What is maceration in the resveratrol extraction process?

Maceration in the resveratrol extraction process is a method where the plant material is soaked in a solvent for a period. This allows resveratrol to dissolve in the solvent.

How does Soxhlet extraction work in resveratrol manufacturing?

Soxhlet extraction is a more continuous and efficient extraction method. It works by repeatedly washing the plant material with a solvent to extract resveratrol.

Why are filtration and centrifugation necessary after extraction?

Filtration and centrifugation are necessary after extraction to refine the extract by removing impurities, ensuring a purer resveratrol extract.

What are the benefits of using crystallization or freeze - drying in the final preparation?

Crystallization or freeze - drying methods in the final preparation of the resveratrol extract make it suitable for use in food products like fortified beverages or health - promoting snacks. These methods can help in obtaining a stable and easily usable form of the extract.

Related literature

- Resveratrol: Sources, Extraction, and Health Benefits in the Food Industry"

- "Advanced Techniques for Resveratrol Extraction in Food - grade Manufacturing"

- "The Role of Resveratrol Extracts in Functional Food Development"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Grapefruit Seed Extract Powder

2024-12-16

-

Curcuma Longa Extract

2024-12-16

-

Calendula Extract

2024-12-16

-

Hedyotis Diffusa Extract

2024-12-16

-

Beetroot juice Powder

2024-12-16

-

White Willow Bark Extract

2024-12-16

-

Boswellia Serrata Extract

2024-12-16

-

Cactus Extract

2024-12-16

-

Feverfew Extract

2024-12-16

-

Curcuma Longa Extract/Turmeric extract

2024-12-16