- 0086-571-85302990

- sales@greenskybio.com

China Astaxanthin Powder Factory.

2024-11-28

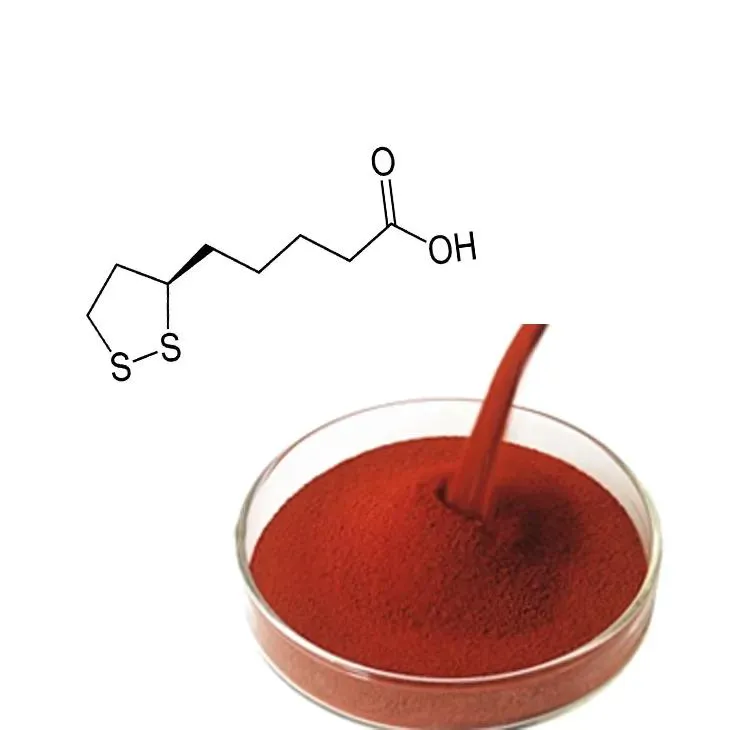

1. Introduction to Astaxanthin Powder

Astaxanthin powder has emerged as a highly valuable ingredient in a wide range of sectors in recent years. It is a powerful antioxidant, known for its various health benefits and applications in the food, cosmetic, and pharmaceutical industries. In China, the production of Astaxanthin powder has been on the rise, with factories playing a crucial role in meeting both domestic and international demands.

2. Geographical and Climatic Advantages in China

China's vast territory offers certain unique geographical and climatic advantages for astaxanthin production.

2.1 Diverse Climates

- China has a wide range of climates, from tropical to temperate zones. This diversity allows for the cultivation of different microalgae species suitable for astaxanthin production. For example, in some warmer southern regions, the climate can support the growth of microalgae with higher growth rates.

- The seasonal variations also play a role. In some areas, the distinct seasons can be managed to optimize the growth cycle of microalgae, ensuring a continuous supply of raw materials for astaxanthin powder production.

2.2 Rich Water Resources

- China has an abundance of water resources, both freshwater and brackish water. Brackish water in coastal areas can be used for the cultivation of certain microalgae species that are rich sources of astaxanthin. The availability of different water qualities provides flexibility in choosing the most suitable cultivation methods.

- Moreover, proper management of water resources, such as water treatment and recycling in factories, can reduce production costs and environmental impacts.

3. Production Sources in Chinese Factories

In China, astaxanthin powder factories mainly utilize two major sources: natural microalgae and synthetic production methods.

3.1 Natural Microalgae - Based Production

- 3.1.1 Microalgae Cultivation Factories carefully cultivate microalgae species that are rich in astaxanthin. These microalgae are typically grown in closed or semi - closed systems to ensure a controlled environment. For instance, in large - scale photobioreactors, factors such as light intensity, temperature, and nutrient supply are precisely regulated. The most commonly used microalgae species include Haematococcus pluvialis, which is known for its high astaxanthin content.

-

3.1.2 Environmental Considerations

- Water quality is of utmost importance. The water used for microalgae cultivation needs to be free from contaminants and have the appropriate nutrient levels. Regular water quality monitoring and treatment are carried out in factories.

- Salinity also affects the growth of microalgae. Different microalgae species have specific salinity requirements, and factories adjust the salinity of the cultivation medium accordingly. For example, some microalgae thrive in slightly saline water, while others prefer freshwater with added salts.

- Sunlight exposure is another crucial factor. Adequate sunlight is necessary for photosynthesis, but excessive sunlight can be harmful. Factories use techniques such as shading or artificial lighting to optimize the light exposure for microalgae growth.

3.2 Synthetic Production

- 3.2.1 Research and Development Chinese factories are increasingly investing in research to optimize the synthetic production of astaxanthin. Synthetic production has the potential to increase production volumes significantly. Scientists in these factories are constantly exploring new chemical synthesis methods and improving existing ones. For example, they are working on more efficient catalysts and reaction conditions to enhance the yield and quality of synthetic astaxanthin.

-

3.2.2 Quality and Efficiency

- One of the main challenges in synthetic production is maintaining the same high - quality standards as natural astaxanthin. Factories use advanced purification techniques to remove impurities and ensure that the synthetic astaxanthin powder meets the required specifications.

- Efficiency in the synthetic production process is also a key focus. By reducing reaction times and minimizing waste generation, factories can lower production costs and increase competitiveness in the market.

4. Quality Control in the Production Process

In the production of astaxanthin powder, strict quality control measures are implemented throughout the entire process, from the initial cultivation or synthesis to the final powder formation.

4.1 Raw Material Inspection

- For natural microalgae - based production, the quality of the microalgae is carefully inspected. This includes checking for the presence of contaminants, such as heavy metals and pesticides. Microscopic examination is often carried out to ensure that the microalgae are healthy and in the correct growth stage.

- In synthetic production, the quality of the starting materials is crucial. Chemical reagents are tested for purity and compliance with industry standards. Any sub - standard materials are rejected to prevent quality issues in the final product.

4.2 Intermediate Process Monitoring

- During the growth of microalgae or the synthesis process, continuous monitoring is carried out. For microalgae, parameters such as cell density, nutrient uptake, and photosynthetic activity are measured regularly. In synthetic production, reaction progress is monitored through various analytical techniques, such as chromatography and spectroscopy.

- Any deviations from the normal process are immediately addressed. For example, if the growth rate of microalgae slows down unexpectedly, corrective actions such as adjusting nutrient levels or environmental conditions are taken. In synthetic production, if a reaction is not proceeding as expected, the reaction conditions may be modified.

4.3 Final Product Analysis

- The astaxanthin powder is subjected to comprehensive analysis before it is released for sale. This includes determining the astaxanthin content, which is typically measured using high - performance liquid chromatography (HPLC). The purity of the powder is also evaluated, ensuring that it meets the required standards.

- Other quality aspects, such as particle size distribution and solubility, are also checked. These properties can affect the performance of the astaxanthin powder in different applications. For example, in the cosmetic industry, a fine particle size and good solubility are often desired for better skin absorption.

5. Domestic and International Market Focus

China's astaxanthin powder factories are not only concerned with domestic demand but also have a strong focus on the international market.

5.1 Domestic Market

- The domestic demand for astaxanthin powder has been growing steadily in China. In the food industry, it is increasingly used as a natural food colorant and antioxidant in products such as dietary supplements, functional foods, and beverages. The rising awareness of health and wellness among consumers has driven the demand for products containing astaxanthin.

- In the cosmetic industry, astaxanthin powder is being incorporated into skincare products due to its antioxidant properties. Chinese consumers are showing more interest in high - quality skincare products with natural ingredients, and astaxanthin fits this trend well.

5.2 International Market

- 5.2.1 Meeting International Standards Chinese factories are constantly adapting to international market requirements. They need to meet different regulatory standards in various countries. For example, in the European Union, there are strict regulations regarding the purity and safety of food additives, including astaxanthin. Chinese factories ensure that their products comply with these regulations through rigorous quality control and testing procedures.

-

5.2.2 Export Opportunities

- The global market for astaxanthin powder is expanding, presenting significant export opportunities for Chinese factories. They are exporting their products to countries all over the world, including the United States, Japan, and South Korea. These countries have a high demand for high - quality astaxanthin powder, especially in the pharmaceutical and nutraceutical industries.

- To enhance their competitiveness in the international market, Chinese factories are also focusing on product innovation and branding. They are developing new formulations and packaging to attract international customers.

6. Contribution to Regional Economic Development

China's astaxanthin powder factories play an important role in the economic development of the regions where they are located.

6.1 Job Creation

- The factories create direct employment opportunities. From the cultivation of microalgae to the production and packaging of astaxanthin powder, a wide range of jobs are available. These include jobs for technicians, laboratory staff, production workers, and quality control personnel.

- Indirectly, they also support employment in related industries. For example, the transportation of raw materials and finished products, as well as the supply of packaging materials, generates jobs in the logistics and packaging industries.

6.2 Promoting Related Industries

- The production of astaxanthin powder stimulates the development of related industries. In the agricultural sector, the demand for certain nutrients and fertilizers for microalgae cultivation can drive the growth of the fertilizer industry. Moreover, the development of high - tech equipment for microalgae cultivation and astaxanthin extraction can promote the growth of the manufacturing industry.

- In the research and development field, the focus on astaxanthin production has led to increased investment in biotechnology and chemical engineering research. This, in turn, can contribute to the overall scientific and technological progress in the region.

7. Future Prospects

With continuous innovation and improvement, China's astaxanthin powder factories are expected to have an even greater impact on the global market in the future.

7.1 Technological Advancements

- Future research is likely to focus on improving the efficiency of both natural microalgae - based and synthetic production methods. This could include the development of more advanced microalgae cultivation systems with higher yields and lower costs. In synthetic production, new synthesis routes may be discovered to further enhance the quality and quantity of astaxanthin produced.

- There will also be an emphasis on developing more sustainable production methods. For example, reducing energy consumption in the production process and minimizing environmental impacts through better waste management.

7.2 Market Expansion

- As the global awareness of astaxanthin's health benefits continues to grow, the market demand is expected to increase further. Chinese factories are well - positioned to capture a larger share of this expanding market. They can expand their product lines to include more specialized astaxanthin - based products for different applications, such as in the medical field for treating certain diseases.

- Collaboration with international partners will also play a role in market expansion. Chinese factories can form strategic alliances with foreign companies for research, production, and marketing, which can help them access new markets and technologies.

FAQ:

What are the main sources of astaxanthin powder in China's factories?

China's astaxanthin powder factories mainly rely on two sources: natural microalgae and synthetic production methods. For natural microalgae - based production, factories cultivate microalgae species rich in astaxanthin. And they are also investing in research to optimize the synthetic production.

How do Chinese factories ensure the quality of astaxanthin powder?

In the production process, from the initial cultivation or synthesis to the final powder formation, strict quality control measures are in place. This involves multiple stages of testing, from raw material inspection to the final product analysis.

Are China's astaxanthin powder factories only for domestic use?

No, China's astaxanthin powder factories are not only focused on domestic demand but also on exporting their products. They are constantly adapting to international market requirements, such as meeting different regulatory standards in various countries.

What role do China's astaxanthin powder factories play in local economic development?

They contribute to the economic development of the regions where they are located. They create jobs and promote related industries.

What factors need to be considered in cultivating microalgae for astaxanthin production?

When cultivating microalgae for astaxanthin production, factors like water quality, salinity, and sunlight exposure need to be considered as these microalgae are grown in carefully managed environments.

Related literature

- Advances in Astaxanthin Production in China"

- "China's Astaxanthin Industry: Current Situation and Future Prospects"

- "Quality Control in Chinese Astaxanthin Powder Manufacturing"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

The best olive leaf extract in nature.

2024-11-28

-

Cordyceps extract suppliers.

2024-11-28

-

Chinese aguaje extract powder manufacturers.

2024-11-28

-

Honeysuckle pollen of the best quality.

2024-11-28

-

Chinese Senna Leaf Extract Suppliers.

2024-11-28

-

Organic Dandelion Root Extract, Australia.

2024-11-28

-

The best bitter gourd extract in 2024.

2024-11-28

-

The best baicalin in nature.

2024-11-28

-

Saffron Extract Powder

2024-11-28

-

Milk Thistle Extract

2024-11-28

-

Licorice Root Extract Powder

2024-11-28

-

Curcumin Extract

2024-11-28

-

Selenium yeast

2024-11-28

-

Green coffee bean Extract

2024-11-28

-

Artichoke Leaf Extract

2024-11-28

-

Senna Leaf Extract

2024-11-28

-

Rosemary extract

2024-11-28

-

Calendula Extract

2024-11-28