- 0086-571-85302990

- sales@greenskybio.com

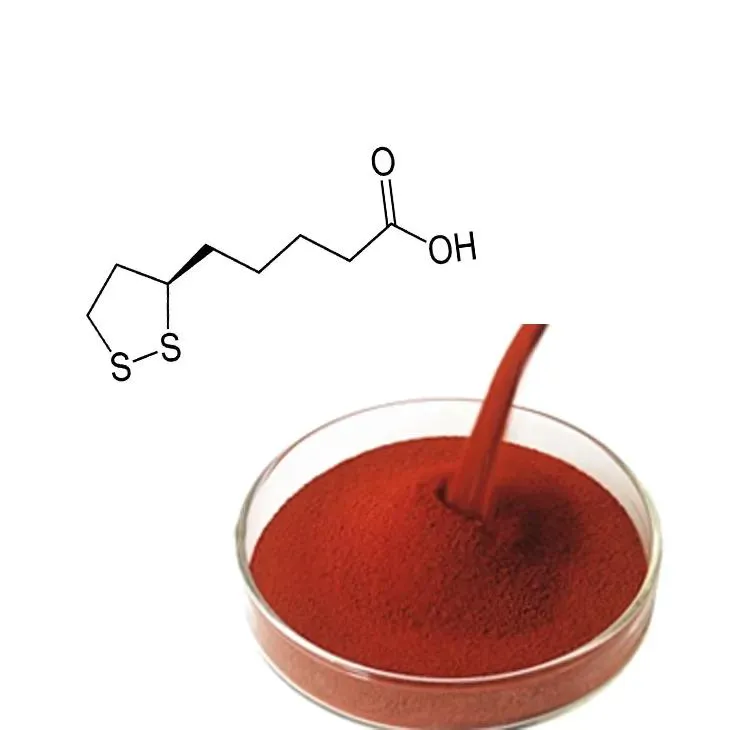

Chinese astaxanthin manufacturers.

2024-12-01

1. Introduction

Astaxanthin manufacturing in China has emerged as a significant and expanding industry. This industry has been growing steadily, with Chinese manufacturers making a name for themselves on the global stage. Astaxanthin, a powerful antioxidant, has a wide range of applications in various sectors such as aquaculture, health supplements, and cosmetics.

2. Adaptability to Different Production Scales

2.1 Large - scale Manufacturers

Large - scale Chinese Astaxanthin manufacturers play a crucial role in meeting the global market demands. In

the field of aquaculture, for instance, there is a high - volume need for astaxanthin. Farmed fish, such as

salmon, trout, and shrimp, require astaxanthin to develop their characteristic pink or red color, which is

highly desired by consumers. Additionally, astaxanthin also enhances the health of these farmed aquatic

organisms, improving their resistance to diseases and stress.

These large - scale manufacturers are equipped with advanced production facilities and efficient production

lines. They can produce astaxanthin in large quantities, ensuring a stable supply to the global market. Their

production capacity allows them to enter into long - term contracts with major international buyers,

contributing to the growth of the global aquaculture industry.

2.2 Small and Medium - sized Enterprises

Small and medium - sized enterprises (SMEs) in the Chinese astaxanthin manufacturing sector are also quite

active. They have identified niche markets and are focusing on them. For example, in the high - end health

supplement market, consumers are increasingly interested in products containing astaxanthin due to its

antioxidant properties. SMEs are able to develop specialized health supplement products, formulating

astaxanthin with other beneficial ingredients to target specific health concerns such as eye health, skin

health, and immune system support.

In the luxury cosmetics industry, astaxanthin is used for its anti - aging and skin - enhancing properties. SMEs

in China are leveraging this opportunity by customizing astaxanthin - based cosmetic products. They are known

for their flexibility in product formulation, being able to quickly adapt to changing market trends and

consumer demands. For instance, they can create different textures, colors, and application forms of

cosmetics containing astaxanthin, such as creams, serums, and masks.

3. Sustainable Production Methods

Sustainable production has become a key focus for Chinese astaxanthin manufacturers. Astaxanthin production

can have certain environmental impacts, particularly in terms of water usage and waste management.

- In terms of water usage, some manufacturers are investing in water - recycling technologies. By treating and

reusing the water in the production process, they can significantly reduce their freshwater consumption. For

example, advanced filtration and purification systems are being installed to ensure that the recycled water

meets the quality requirements for astaxanthin production.

- Regarding waste management, Chinese manufacturers are exploring ways to minimize waste generation and

properly dispose of any waste produced. Some are researching methods to convert waste products into useful

by - products. For instance, the residues from astaxanthin extraction can potentially be used in other

industries, such as in the production of animal feed or bio - fertilizers.

- Moreover, many manufacturers are also looking into alternative sources of raw materials for astaxanthin

production. Instead of relying solely on traditional sources, they are investigating the use of sustainable

biomass or microorganisms that can produce astaxanthin more efficiently and with less environmental impact.

4. Research and Development Collaborations

Chinese astaxanthin manufacturers are actively engaged in research and development (R & D) collaborations

with both domestic and international research institutions.

- Domestically, they are partnering with universities and research centers. These collaborations enable them to

access the latest scientific knowledge and research facilities in China. For example, some manufacturers are

working with Chinese universities to study new extraction methods for astaxanthin. This could lead to more

efficient and cost - effective ways of obtaining astaxanthin from its sources.

- Internationally, Chinese manufacturers are also forging partnerships. By collaborating with international

research institutions, they can gain insights into global trends and best practices in astaxanthin

manufacturing. This includes learning about the latest purification techniques and formulation methods used in

other countries. These international collaborations also help Chinese manufacturers to meet international

quality and safety standards more easily, facilitating their entry into global markets.

- In addition, through these R & D collaborations, Chinese manufacturers are able to contribute to the

scientific knowledge base in astaxanthin production. They can share their own experiences and data, which may

lead to new discoveries and innovations in the field. For example, they may provide unique insights on how to

optimize astaxanthin production under different environmental conditions or with different raw materials.

5. Quality Control and Standardization

Quality control is of utmost importance in the Chinese astaxanthin manufacturing industry. Manufacturers

are implementing strict quality control measures at every stage of the production process.

- Raw material sourcing: They carefully select the sources of raw materials to ensure high - quality

astaxanthin. This involves screening suppliers based on factors such as the purity of the raw materials, their

origin, and the sustainability of the sourcing methods. For example, if the raw material is obtained from

microalgae, the manufacturers will ensure that the microalgae are grown in a clean and controlled environment.

- Production process monitoring: During the production process, various parameters are closely monitored.

These include temperature, pressure, and reaction time in the extraction and purification processes. Any

deviation from the optimal values can affect the quality of the final astaxanthin product. Advanced

monitoring equipment and automated control systems are used to ensure that the production process remains

within the specified parameters.

- Product testing: Before the astaxanthin products are released to the market, comprehensive testing is

carried out. This includes tests for purity, potency, and stability. The products must meet the relevant

national and international standards. For example, in the case of astaxanthin used in health supplements, it

must meet the safety and efficacy standards set by regulatory bodies such as the Food and Drug

Administration in different countries.

6. Market Competitiveness

Chinese astaxanthin manufacturers have several factors contributing to their market competitiveness.

- Cost - effectiveness: China has certain advantages in terms of production costs. The availability of raw

materials, relatively lower labor costs, and the scale of production all contribute to cost - effective

production. This allows Chinese manufacturers to offer competitive prices in the global market, making their

products attractive to international buyers.

- Technological innovation: Through continuous R & D efforts and collaborations, Chinese manufacturers are

able to introduce innovative products and production methods. For example, they may develop new forms of

astaxanthin delivery systems in health supplements, such as nano - emulsions or liposomes, which can improve

the bioavailability of astaxanthin. This technological edge gives them an advantage over competitors in the

market.

- Product diversity: As mentioned earlier, the presence of both large - scale and SMEs in the industry leads to

a diverse range of astaxanthin products. This diversity caters to different market segments and consumer

needs, from high - volume aquaculture applications to niche - market health supplements and cosmetics.

7. Future Outlook

The future of Chinese astaxanthin manufacturers looks promising.

- Market expansion: The global demand for astaxanthin is expected to continue to grow. As more consumers become

aware of the health benefits of astaxanthin and as the aquaculture industry expands further, there will be

increasing opportunities for Chinese manufacturers. They are likely to expand their market share both

domestically and internationally.

- Technological advancements: With ongoing R & D efforts, new technologies for astaxanthin production are

likely to emerge. This could include more efficient extraction methods, improved purification techniques, and

enhanced formulation strategies. Chinese manufacturers are well - positioned to adopt these new

technologies, further enhancing their competitiveness in the global market.

- Sustainability focus: The trend towards sustainable production will continue to gain momentum. Chinese

manufacturers are expected to further invest in sustainable production methods, which will not only help

protect the environment but also meet the growing demand for environmentally - friendly products from

consumers.

FAQ:

What are the advantages of large - scale Chinese astaxanthin manufacturers?

Large - scale Chinese astaxanthin manufacturers have the advantage of being able to meet high - volume demands. For example, in the aquaculture industry which requires large amounts of astaxanthin to improve the color and health of farmed fish, they can supply sufficient quantities to the global market.

How do small and medium - sized Chinese astaxanthin manufacturers operate?

Small and medium - sized Chinese astaxanthin manufacturers usually focus on niche markets such as high - end health supplements and luxury cosmetics. They are recognized for their flexibility in product formulation and customization.

What are Chinese astaxanthin manufacturers doing regarding sustainable production?

Given the environmental issues related to astaxanthin production like water usage and waste management, Chinese manufacturers are investing in green technologies. This helps them reduce their environmental footprint while still maintaining high - quality production.

How do Chinese astaxanthin manufacturers keep up with technological advancements?

Chinese astaxanthin manufacturers collaborate with domestic and international research institutions. Through this cooperation, they can stay at the forefront of technological progress in astaxanthin extraction, purification, and formulation.

What are the main application areas of astaxanthin produced by Chinese manufacturers?

The main application areas include aquaculture, where it is used to enhance the color and health of farmed fish, as well as high - end health supplements and luxury cosmetics in the case of products from small and medium - sized manufacturers.

Related literature

- Advances in Astaxanthin Production in China"

- "Sustainable Astaxanthin Manufacturing in China: A Review"

- "The Role of Chinese Manufacturers in the Global Astaxanthin Market"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

The best lemon juice powder in nature.

2024-12-01

-

Organic Vitamin K2 Powder Suppliers

2024-12-01

-

Bulk purchase of L - tyrosine.

2024-12-01

-

Vitamin K2 Manufacturers

2024-12-01

-

100% Pure Natural Rutin.

2024-12-01

-

Chinese Citrus Bioflavonoid Suppliers.

2024-12-01

-

Citrus Aurantii Extract

2024-12-01

-

Panax Ginseng Leaf Extract

2024-12-01

-

Marigold Extract

2024-12-01

-

Beta Carotene

2024-12-01

-

Withania Somnifera Extract

2024-12-01

-

Maitake Mushroom Extract

2024-12-01

-

Avocado Extract Powder

2024-12-01

-

Maca Extract

2024-12-01

-

Rosemary extract

2024-12-01

-

Quercetin

2024-12-01