- 0086-571-85302990

- sales@greenskybio.com

Chinese Saw Palmetto Extract Factories.

2024-11-30

Location and Resource Advantage

China has emerged as an important player in the production of Saw Palmetto Extract with its specialized factories. These factories are strategically located in areas with rich natural resources and convenient transportation. Rich natural resources provide a solid foundation for the production of Saw Palmetto Extract. Areas with abundant saw palmetto plants can ensure a stable supply of raw materials. Meanwhile, convenient transportation is crucial for the factories to transport raw materials in and finished products out. It not only reduces the cost of transportation but also shortens the delivery time, enabling the products to reach customers at home and abroad more quickly.

The Production Process

Raw Material Supply Chain

The production process in Chinese Saw Palmetto Extract factories is a comprehensive one. First, they have established stable raw material supply chains. This is of great significance for the production of high - quality saw palmetto extract. A stable supply chain allows for a continuous supply of fresh saw palmetto for extraction. The factories usually cooperate with local farmers or raw material suppliers. They ensure that the saw palmetto plants are harvested at the right time to maintain their best quality. For example, they may have strict agreements on the time of harvest, the method of collection, and the storage conditions of the raw materials.

Combination of Traditional and Modern Techniques

Then, in the extraction process, Chinese factories combine traditional extraction wisdom with modern scientific techniques. Traditional extraction wisdom has been passed down for generations in China. It often contains some unique and effective extraction methods. For instance, some traditional extraction methods can better preserve the active ingredients in saw palmetto. At the same time, modern scientific techniques play a vital role. Advanced extraction equipment such as supercritical fluid extraction machines are used in the factories. These machines can extract the active ingredients in saw palmetto more efficiently and accurately. By combining the two, the factories can produce saw palmetto extract with high purity and good quality.

Environmental Protection in Production

Chinese factories also focus on environmental protection during production. They strive to minimize waste and pollution, which is in line with global sustainable development trends. In the extraction process, the factories use environmentally friendly solvents as much as possible. For example, some solvents are biodegradable, which can reduce the harm to the environment. Moreover, the factories have waste treatment systems. Waste treatment systems are designed to deal with the waste generated during the production process. They can recycle some of the waste materials and treat the harmful substances properly. For example, the wastewater generated during extraction is treated to meet the environmental protection standards before being discharged.

Product Variety

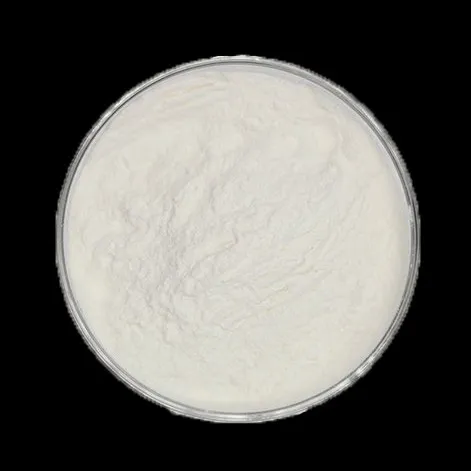

In terms of product variety, Chinese saw palmetto extract factories can produce different forms of saw palmetto extract, such as powder and liquid, to meet the diverse needs of customers at home and abroad. Powder form is convenient for storage and transportation. It can be easily used in the production of various health products. For example, it can be added to dietary supplements in powder form. Liquid form is more suitable for some products that require direct use, such as some topical medications. The factories can adjust the production process according to the different forms of products required by customers, ensuring that they can provide the most suitable products.

Quality Management System

Their strict quality management system, from raw material inspection to final product packaging, ensures that every batch of saw palmetto extract leaving the factory is of high quality. Raw material inspection is the first step in quality control. The factories will test the quality of saw palmetto raw materials, including the content of active ingredients, the presence of impurities, etc. Only the raw materials that meet the standards will be used for production. During the production process, there are strict process control and quality monitoring. For example, the extraction temperature, pressure, and time are all carefully controlled to ensure the stability of product quality. Final product packaging also plays an important role in quality management. The packaging materials are carefully selected to ensure that they can protect the product from moisture, light, and other factors that may affect the quality of the product.

Contribution to the Global Market

Chinese saw palmetto extract factories are thus well - positioned to contribute to the global saw palmetto extract market. With their advantages in production, environmental protection, product variety, and quality management, they can meet the needs of customers around the world. They can provide high - quality saw palmetto extract products at competitive prices. In addition, Chinese factories are also constantly exploring new markets and customers. They participate in international exhibitions and trade fairs to promote their products. Through cooperation with international partners, they can further expand their influence in the global market and contribute to the development of the global saw palmetto extract industry.

FAQ:

Q1: Where are the Chinese saw palmetto extract factories usually located?

They are located in areas with rich natural resources and convenient transportation.

Q2: How does the production process in Chinese saw palmetto extract factories work?

First, they establish stable raw material supply chains for a continuous supply of fresh saw palmetto for extraction. Then, they combine traditional extraction wisdom with modern scientific techniques during the extraction process.

Q3: What do Chinese saw palmetto extract factories do regarding environmental protection?

They strive to minimize waste and pollution during production, which is in line with global sustainable development trends.

Q4: What product varieties can Chinese saw palmetto extract factories produce?

They can produce different forms of saw palmetto extract, such as powder and liquid, to meet the diverse needs of customers at home and abroad.

Q5: How do Chinese saw palmetto extract factories ensure product quality?

They have a strict quality management system, from raw material inspection to final product packaging, which ensures that every batch of saw palmetto extract leaving the factory is of high quality.

Related literature

- Title: Saw Palmetto Extract: Production and Quality Control in China"

- Title: "The Role of Chinese Factories in the Global Saw Palmetto Extract Market"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

The best lemon juice powder in nature.

2024-11-30

-

Organic Vitamin K2 Powder Suppliers

2024-11-30

-

Bulk purchase of L - tyrosine.

2024-11-30

-

Vitamin K2 Manufacturers

2024-11-30

-

100% Pure Natural Rutin.

2024-11-30

-

Chinese Citrus Bioflavonoid Suppliers.

2024-11-30

-

Alisma Extract

2024-11-30

-

Senna Leaf Extract

2024-11-30

-

Aminolevulinic acid

2024-11-30

-

Chia Seed Powder

2024-11-30

-

Chaste Berry Extract

2024-11-30

-

Eucommia Ulmoides Extract

2024-11-30

-

Natural grape seed extract

2024-11-30

-

Pueraria Lobata Extract

2024-11-30

-

Beta Carotene

2024-11-30

-

Epimedium extract powder

2024-11-30