- 0086-571-85302990

- sales@greenskybio.com

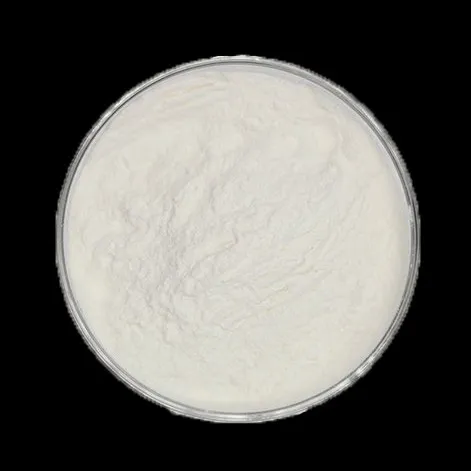

Extract Saw Palmetto Extract by Steam Distillation.

2024-11-30

1. Introduction to Saw Palmetto

Saw palmetto (Serenoa repens) is a small palm tree native to the southeastern United States, particularly Florida. It has been widely recognized for its medicinal properties and has a long history of use in traditional medicine. The plant is characterized by its fan - shaped leaves and small, dark berries. These berries are the main source of the valuable substances that are of interest in the production of Saw Palmetto Extract.

2. Importance of Saw Palmetto Extract

The Saw Palmetto Extract is highly sought after in various fields, especially in health - care and natural medicine. It is believed to have several beneficial effects on human health. For example, it has been studied for its potential role in treating benign prostatic hyperplasia (BPH), a common condition in men as they age. The extract may help to relieve some of the symptoms associated with BPH, such as urinary problems. Additionally, it is also being investigated for its anti - inflammatory properties and its potential impact on hormonal balance.

3. The Basics of Steam Distillation

3.1 Definition

Steam distillation is a separation process that is commonly used in the extraction of essential oils and other volatile compounds from plant materials. It is based on the principle that when steam is passed through a plant material, the volatile components in the plant are carried away with the steam. This is possible because the volatile compounds have a certain vapor pressure, and when the steam is introduced, they vaporize along with the steam.3.2 Equipment Used

- Steam Generator: This is the source of the steam. It can be a simple boiler or a more sophisticated device that can control the pressure and flow rate of the steam.

- Distillation Flask: The plant material, in this case, saw palmetto, is placed in the distillation flask. The steam is passed through this flask, and the volatile compounds are vaporized.

- Condenser: After the vaporized mixture of steam and volatile compounds leaves the distillation flask, it enters the condenser. The condenser cools the vapor, causing it to turn back into a liquid state.

- Receiver Flask: The condensed liquid, which is the saw palmetto extract along with water, is collected in the receiver flask.

4. The Steam Distillation Process for Saw Palmetto Extract

4.1 Preparation of Saw Palmetto

Before the steam distillation process can begin, the saw palmetto berries need to be properly prepared. This typically involves cleaning the berries to remove any dirt, debris, or foreign matter. They may also be dried to a certain extent, although fresh berries can also be used in some cases. Once the berries are clean and ready, they are placed in the distillation flask.4.2 Introduction of Steam

- The steam generator is activated, and steam is introduced into the distillation flask containing the saw palmetto berries. The steam should be introduced at a controlled rate to ensure proper extraction. If the steam is introduced too quickly, it may not have enough time to interact with all the volatile compounds in the plant material.

- As the steam passes through the berries, it begins to heat up the plant material. This heat causes the volatile compounds within the saw palmetto to vaporize. These volatile compounds include various substances such as fatty acids, sterols, and other bioactive components that are of interest in the extract.

4.3 Vapor Transport and Condensation

- The vaporized mixture of steam and volatile compounds then travels from the distillation flask to the condenser. The condenser is usually a coiled tube surrounded by a coolant, such as cold water. As the vapor passes through the condenser, it is rapidly cooled.

- The cooling process causes the vapor to condense back into a liquid state. Since the steam and the volatile compounds were vaporized together, they now form a liquid mixture in the condenser. This liquid mixture then flows down into the receiver flask.

4.4 Separation of the Extract

- In the receiver flask, the liquid mixture contains both the saw palmetto extract and water. Since the extract is hydrophobic (does not mix well with water), it can be separated from the water using techniques such as decantation or extraction with an organic solvent.

- Decantation involves carefully pouring off the water layer, leaving the saw palmetto extract behind. If extraction with an organic solvent is used, a solvent such as hexane or ethyl acetate can be added to the mixture. The extract will dissolve in the organic solvent, and then the solvent can be evaporated to obtain the pure saw palmetto extract.

5. Factors Affecting the Steam Distillation of Saw Palmetto Extract

5.1 Temperature

The temperature at which the steam distillation is carried out is crucial. If the temperature is too low, the volatile compounds may not vaporize completely, resulting in a lower yield of the extract. On the other hand, if the temperature is too high, it may cause the degradation of some of the valuable components in the saw palmetto. Therefore, a carefully controlled temperature is necessary to ensure the optimal extraction of the extract.5.2 Pressure

The pressure of the steam also affects the distillation process. Higher steam pressure can increase the rate of vaporization of the volatile compounds, but it also requires more robust equipment. Additionally, improper pressure control can lead to problems such as the bursting of the distillation flask or the formation of unwanted by - products.5.3 Duration of Distillation

The length of time that the steam distillation process is carried out is another important factor. A longer distillation time may result in a more complete extraction of the volatile compounds, but it also increases the risk of over - extraction and the degradation of the extract. Therefore, the optimal distillation time needs to be determined based on the characteristics of the saw palmetto and the desired quality of the extract.6. Quality Control of Saw Palmetto Extract Obtained by Steam Distillation

6.1 Purity Analysis

One of the key aspects of quality control is to ensure the purity of the saw palmetto extract. This can be done through various analytical techniques such as gas chromatography - mass spectrometry (GC - MS). GC - MS can identify and quantify the different components in the extract, allowing for the detection of any impurities or contaminants.6.2 Potency Testing

Since the effectiveness of the saw palmetto extract in health - care applications depends on its potency, it is essential to test the potency of the extract. This can involve in - vitro and in - vivo assays to determine the biological activity of the extract. For example, tests can be carried out to measure its anti - inflammatory activity or its effect on prostate cells in the case of its use for BPH.6.3 Standardization

To ensure consistent quality of the saw palmetto extract, standardization is necessary. This involves setting standards for the content of key components in the extract, such as the amount of fatty acids or sterols. By adhering to these standards, manufacturers can produce extracts with reliable and reproducible quality.7. Conclusion

Steam distillation is a valuable method for obtaining saw palmetto extract. It allows for the efficient separation of the valuable volatile compounds from the plant material while maintaining the quality and potency of the extract. However, several factors need to be carefully considered during the distillation process, including temperature, pressure, and duration. Quality control measures are also essential to ensure the purity, potency, and standardization of the extract. With proper implementation of the steam distillation process and quality control, saw palmetto extract can be effectively produced for use in health - care and natural medicine applications.

FAQ:

What is the principle behind steam distillation for saw palmetto extract?

The principle is that when steam is introduced to the saw palmetto source, the volatile compounds in the plant are carried away by the steam. As the steam - compound mixture is cooled, the steam turns back into water and the volatile compounds are separated out, forming the extract.

Why is steam distillation a preferred method for saw palmetto extract?

Steam distillation is preferred because it effectively separates the valuable substances from the saw palmetto plant while maintaining the quality and potency of the extract. It is a relatively gentle method that can preserve the medicinal properties of the plant for applications in healthcare and natural medicine.

What are the main steps in the steam distillation process for saw palmetto extract?

The main steps include introducing steam to the saw palmetto source. The steam then passes through the plant material, carrying the volatile compounds. After that, the steam - compound mixture is cooled, causing the steam to condense back into liquid and the volatile compounds to be collected as the saw palmetto extract.

How does steam distillation help in maintaining the quality of saw palmetto extract?

Steam distillation helps maintain quality as it is a mild extraction method. It selectively extracts the volatile compounds without causing excessive degradation or chemical changes to the valuable substances in the saw palmetto. This ensures that the extract retains its medicinal properties and potency.

What are the potential applications of saw palmetto extract obtained by steam distillation?

The extract has potential applications in healthcare and natural medicine. It may be used for various purposes related to the medicinal properties of saw palmetto, such as in the treatment of certain health conditions or as part of natural remedies.

Related literature

- Steam Distillation of Medicinal Plants: A Review"

- "Optimization of Steam Distillation for Extracting Bioactive Compounds from Saw Palmetto"

- "The Role of Steam Distillation in Extracting High - Quality Saw Palmetto Extract for Therapeutic Use"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

Standard - process green tea extract.

2024-11-30

-

100% Organic Calendula Extract.

2024-11-30

-

Wholesale Mulberry Leaf Extract Suppliers.

2024-11-30

-

Scutellaria Extract

2024-11-30

-

Dandelion Root Extract

2024-11-30

-

Carrageenan Extract Powder

2024-11-30

-

Okra Extract

2024-11-30

-

Citrus Aurantii Extract

2024-11-30

-

Tormentil Extract

2024-11-30

-

Oat Straw Extract Powder

2024-11-30

-

Saffron Extract Powder

2024-11-30

-

Rose Hip Extract

2024-11-30

-

Beta Carotene

2024-11-30