- 0086-571-85302990

- sales@greenskybio.com

Extraction Technology and Production Process of Eucommia ulmoides Extract

2024-11-30

1. Introduction

Eucommia ulmoides, a well - known traditional Chinese medicinal plant, has been widely used for its various health - promoting properties. The extract of Eucommia ulmoides contains a rich variety of bioactive components, such as flavonoids, iridoids, lignans, and polysaccharides. These components are associated with antioxidant, anti - inflammatory, antihypertensive, and other pharmacological effects. Therefore, the extraction technology and production process of Eucommia Ulmoides Extract play a crucial role in ensuring the quality and efficacy of the final product, which are of great significance for related industries and scientific research.

2. Traditional Extraction Methods

2.1. Solvent Extraction

2.1.1. Water Extraction

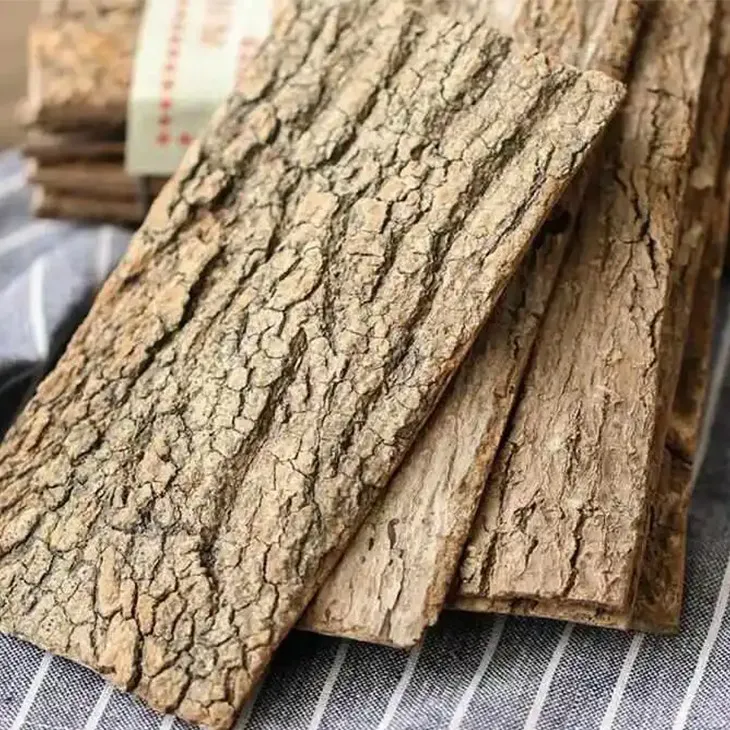

- Water extraction is one of the most basic traditional methods. The process involves soaking the Eucommia ulmoides raw materials in water for a certain period, usually several hours to days.

- Then, the mixture is heated under reflux or boiled to dissolve the water - soluble components. After that, the liquid is separated from the solid residue through filtration or centrifugation.

- The advantages of water extraction include its simplicity, low cost, and environmental friendliness since water is a non - toxic solvent. However, the extraction efficiency may be relatively low, and it may extract a large amount of impurities simultaneously.

- Ethanol extraction is also commonly used. Ethanol, with different concentrations (usually 30% - 95%), is used as the solvent. The Eucommia ulmoides materials are soaked in ethanol, and the extraction is carried out in a similar way as water extraction.

- Compared with water extraction, ethanol extraction can dissolve more lipophilic components in addition to water - soluble ones. It has a relatively higher extraction efficiency for some active components. However, ethanol is flammable, which requires certain safety precautions during the production process.

2.2. Maceration

- Maceration is a traditional extraction method that involves soaking the Eucommia ulmoides materials in a solvent (such as water or ethanol) for a long time, usually weeks or even months. During this process, the solvent gradually penetrates into the plant tissues, and the active components are dissolved out.

- The advantage of maceration is that it can achieve a relatively complete extraction of active components. However, it is a time - consuming process, and there is a risk of microbial growth during the long - term soaking, which may affect the quality of the extract.

3. Modern Extraction Technologies

3.1. Supercritical Fluid Extraction (SFE)

- Supercritical fluid extraction uses supercritical carbon dioxide (CO₂) as the extraction solvent. Supercritical CO₂ has properties between gas and liquid, such as high diffusivity, low viscosity, and adjustable density.

- In the SFE process, the Eucommia ulmoides materials are placed in an extraction vessel, and supercritical CO₂ is passed through. The supercritical CO₂ can selectively dissolve the target components from the materials. Then, by changing the pressure and temperature, the dissolved components can be separated from the CO₂.

- The main advantages of SFE are its high extraction efficiency, short extraction time, and the ability to obtain extracts with high purity. Moreover, since CO₂ is non - toxic, non - flammable, and easily removed from the extract, it is an environmentally friendly extraction method. However, the equipment for SFE is relatively expensive, which may limit its widespread application in some small - scale production.

3.2. Ultrasonic - Assisted Extraction (UAE)

- Ultrasonic - assisted extraction utilizes ultrasonic waves to enhance the extraction process. When ultrasonic waves are applied to the extraction system containing Eucommia ulmoides materials and solvent, the cavitation effect is generated.

- The cavitation effect can cause micro - bubbles to form, grow, and collapse violently in the solvent, which creates local high - temperature and high - pressure environments. These extreme conditions can break the cell walls of the plant materials more effectively, thereby increasing the release of active components into the solvent.

- UAE has the advantages of high extraction efficiency, short extraction time, and relatively simple equipment requirements. It can be combined with traditional extraction methods such as solvent extraction to further improve the extraction yield.

3.3. Microwave - Assisted Extraction (MAE)

- Microwave - assisted extraction uses microwave energy to heat the extraction system. The microwave can directly interact with the polar molecules in the Eucommia ulmoides materials and the solvent, causing rapid heating.

- This rapid heating can lead to the expansion of plant cells and the acceleration of mass transfer processes, which is beneficial for the extraction of active components. MAE has the characteristics of high efficiency, energy - saving, and short extraction time.

- However, the microwave - assisted extraction process needs to be carefully controlled to avoid overheating and decomposition of some active components. Also, the equipment for MAE needs to meet certain safety requirements due to the use of microwave energy.

4. Quality Control in the Production Process

4.1. Raw Material Quality

- The quality of Eucommia ulmoides raw materials is the foundation for ensuring the quality of the extract. High - quality raw materials should be selected, which are required to come from reliable sources, such as well - managed plantations.

- The growth environment, including soil quality, climate, and altitude, can affect the content and quality of active components in Eucommia ulmoides. For example, plants grown in suitable soil with appropriate sunlight and rainfall are more likely to contain higher levels of bioactive substances.

- Also, the harvesting time and processing methods of raw materials are important factors. Appropriate harvesting time can ensure that the active components are at their peak content, and proper processing methods can prevent the degradation of active components during storage and pretreatment.

4.2. Extraction Process Monitoring

- During the extraction process, various parameters need to be monitored to ensure the quality and reproducibility of the extract. These parameters include extraction time, temperature, solvent concentration, and extraction pressure (for methods like SFE).

- For example, in solvent extraction, if the extraction time is too short, the extraction may be incomplete, while if it is too long, it may lead to the extraction of excessive impurities. Similarly, the temperature should be controlled within an appropriate range to avoid the decomposition of active components.

- Modern extraction equipment is often equipped with sensors and monitoring systems to accurately measure and control these parameters. This can help to produce extracts with consistent quality and meet the requirements of different applications.

4.3. Purification and Concentration

- After extraction, the obtained crude extract usually contains a large amount of impurities, such as pigments, proteins, and other non - target components. Therefore, purification and concentration steps are necessary.

- Common purification methods include filtration, centrifugation, and chromatography. Filtration and centrifugation can remove large - particle impurities, while chromatography can separate the target components from other components based on their different physical and chemical properties.

- Concentration is mainly carried out to increase the content of active components in the extract. This can be achieved by methods such as evaporation under reduced pressure or freeze - drying. Through these purification and concentration steps, the quality of the final Eucommia Ulmoides Extract can be significantly improved.

5. Environmental Impact of the Production Process

5.1. Traditional Extraction Methods

- Traditional solvent extraction methods, especially those using large amounts of organic solvents such as ethanol, may have certain environmental impacts. The use and disposal of organic solvents can cause air pollution and water pollution if not properly managed.

- For example, the evaporation of ethanol during the extraction process may release volatile organic compounds (VOCs) into the atmosphere, contributing to air pollution. And if the waste ethanol is discharged directly into water bodies, it can cause water quality degradation.

- Although water extraction is relatively environmentally friendly, a large amount of wastewater may be generated, which also needs to be properly treated to avoid environmental pollution.

5.2. Modern Extraction Technologies

- Supercritical fluid extraction using CO₂ has a relatively small environmental impact. Since CO₂ is a natural gas, it is non - toxic and non - polluting. And after the extraction, the CO₂ can be recycled and reused, reducing the overall environmental footprint.

- Ultrasonic - assisted extraction and microwave - assisted extraction mainly rely on physical energy sources, and their environmental impact is mainly related to the energy consumption of the equipment. However, compared with traditional extraction methods, they generally consume less energy and produce less pollution due to their high - efficiency extraction characteristics.

6. Conclusion

In conclusion, the extraction technology and production process of Eucommia Ulmoides Extract have experienced continuous development from traditional methods to modern advanced technologies. Each extraction method has its own advantages and disadvantages in terms of extraction efficiency, quality control, and environmental impact. Traditional extraction methods are simple and low - cost but may have relatively low extraction efficiency and certain environmental problems. Modern extraction technologies, such as supercritical fluid extraction, ultrasonic - assisted extraction, and microwave - assisted extraction, offer higher extraction efficiency, better quality control, and relatively smaller environmental impact, but may require more expensive equipment and higher - level technical operation. Therefore, in the actual production of Eucommia ulmoides extract, it is necessary to comprehensively consider various factors such as product requirements, cost, and environmental protection to select the most suitable extraction method and production process, so as to ensure the production of high - quality Eucommia ulmoides extract and promote the healthy development of related industries.

FAQ:

What are the traditional extraction methods of Eucommia ulmoides extract?

Traditional extraction methods of Eucommia ulmoides extract mainly include solvent extraction. For example, using ethanol as a solvent. The process typically involves soaking the Eucommia ulmoides raw materials in the solvent for a certain period, followed by filtration and concentration to obtain the extract. Another traditional method is water extraction, where water is used to extract the active components from Eucommia ulmoides. However, traditional methods may have some limitations such as relatively low extraction efficiency and longer extraction time.

What are the modern extraction techniques for Eucommia ulmoides extract?

Modern extraction techniques for Eucommia ulmoides extract include supercritical fluid extraction. Supercritical CO2 is often used as the extraction medium. This method has the advantages of high extraction efficiency, selectivity, and it can operate at relatively low temperatures, which helps to preserve the active components. Another modern technique is ultrasonic - assisted extraction. Ultrasonic waves can enhance the mass transfer process during extraction, reducing the extraction time and improving the extraction yield. Microwave - assisted extraction is also a modern approach. Microwave irradiation can rapidly heat the extraction system, increasing the extraction efficiency.

How is the quality of Eucommia ulmoides extract controlled during the production process?

Quality control of Eucommia ulmoides extract during the production process involves several aspects. Firstly, raw material quality is crucial. Only high - quality Eucommia ulmoides should be selected. During the extraction process, parameters such as extraction time, temperature, and solvent concentration need to be strictly controlled. Analytical methods like high - performance liquid chromatography (HPLC) are often used to analyze the content and purity of the active components in the extract. Also, strict quality standards for the final product need to be established, including limits for impurities and ensuring the stability of the extract.

What are the environmental impacts of different extraction methods of Eucommia ulmoides extract?

Traditional solvent extraction methods may have certain environmental impacts. For example, if large amounts of organic solvents are used, there may be issues related to solvent waste disposal. In contrast, supercritical fluid extraction, especially when using CO2 as the supercritical fluid, is relatively more environmentally friendly as CO2 is non - toxic and can be recycled easily. Ultrasonic - assisted and microwave - assisted extraction methods mainly consume energy, but compared to traditional methods, they may reduce the use of solvents and thus have less environmental impact in terms of solvent waste.

How can the extraction efficiency of Eucommia ulmoides extract be improved?

To improve the extraction efficiency of Eucommia ulmoides extract, modern extraction techniques can be employed. As mentioned before, ultrasonic - assisted extraction can break cell walls more effectively through ultrasonic cavitation, facilitating the release of active components. Microwave - assisted extraction can quickly heat the system to increase the solubility of the components. Optimization of extraction parameters such as adjusting the solvent - to - material ratio, extraction time, and temperature also plays an important role. Additionally, pretreatment of the raw materials, such as grinding to a proper particle size, can increase the contact area between the raw materials and the solvent, thereby improving the extraction efficiency.

Related literature

- Studies on the Extraction and Bioactivity of Eucommia ulmoides Extract"

- "Advanced Extraction Technologies for Eucommia ulmoides: A Review"

- "Quality Control and Standardization of Eucommia ulmoides Extract in Industrial Production"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

The best lemon juice powder in nature.

2024-11-30

-

Organic Vitamin K2 Powder Suppliers

2024-11-30

-

Bulk purchase of L - tyrosine.

2024-11-30

-

Vitamin K2 Manufacturers

2024-11-30

-

100% Pure Natural Rutin.

2024-11-30

-

Chinese Citrus Bioflavonoid Suppliers.

2024-11-30

-

Acerola Juice Powder

2024-11-30

-

White mustard seed extract

2024-11-30

-

Motherwort Extract

2024-11-30

-

Marigold Extract

2024-11-30

-

Purple Sweet Potato Extract

2024-11-30

-

Citrus Aurantium Extract

2024-11-30

-

Jujube Extract

2024-11-30

-

Alisma Extract

2024-11-30

-

Golden Seal Extract

2024-11-30

-

Nettle Root Extract

2024-11-30