- 0086-571-85302990

- sales@greenskybio.com

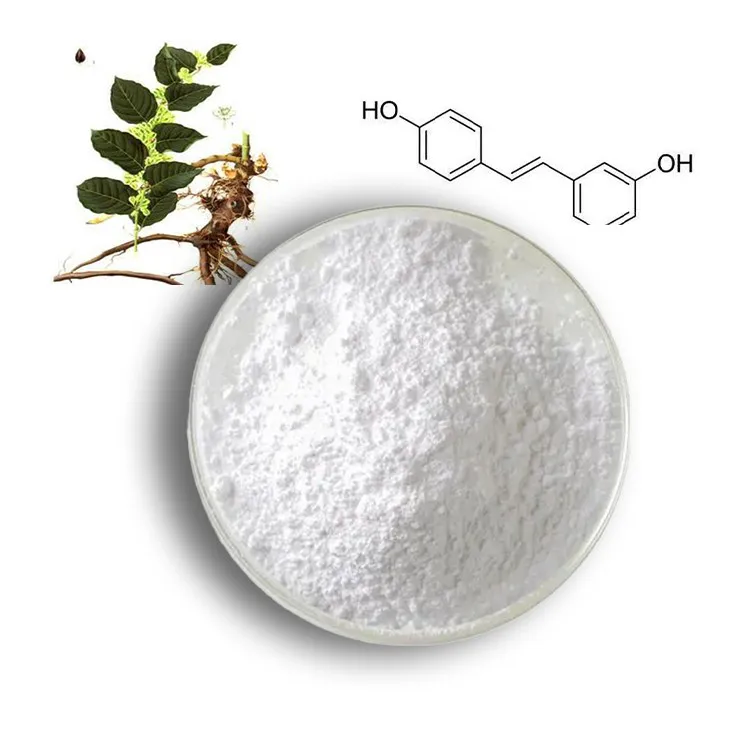

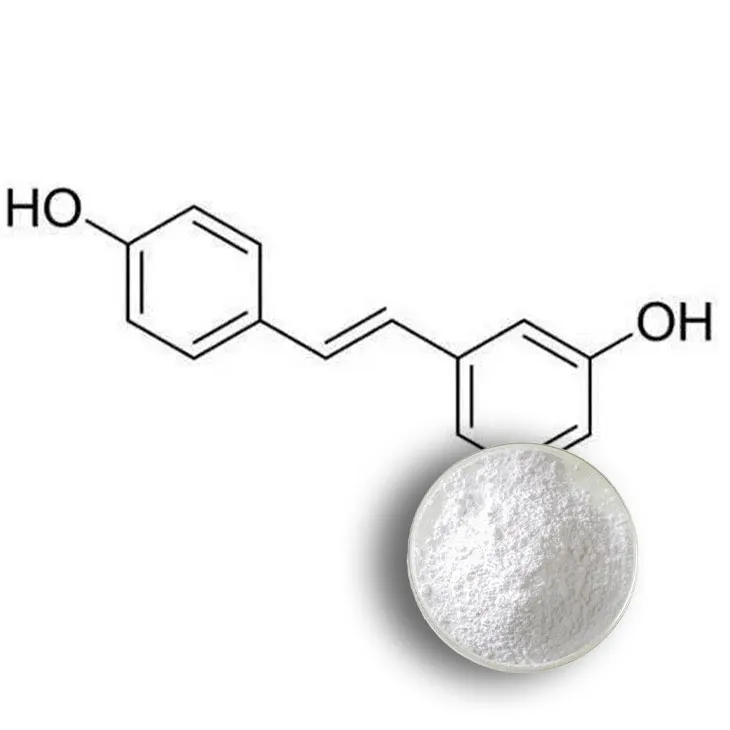

Extraction technology and production process of resveratrol extract.

2024-11-28

Resveratrol, especially white Resveratrol extract, has attracted significant attention in recent years due to its potential health benefits. This article will comprehensively discuss the extraction techniques and production processes of white Resveratrol extract.

1. Introduction to Resveratrol

Resveratrol is a natural phenolic compound that can be found in various plants, such as grapes, peanuts, and some berries. It is known for its antioxidant, anti - inflammatory, and potential anti - cancer properties. White Resveratrol extract is a form of resveratrol that has particular significance in the field of nutraceuticals and pharmaceuticals.

2. Traditional Extraction Methods

2.1 Solvent Extraction

Principle: Solvent extraction is one of the most common traditional methods for extracting resveratrol. It is based on the solubility of resveratrol in different solvents. Resveratrol is more soluble in certain organic solvents than in water.

Procedure:

- First, the raw materials (such as grape skins or seeds) are dried and ground into a fine powder.

- Then, an appropriate solvent, such as ethanol or methanol, is added to the powdered raw material. The mixture is stirred thoroughly to ensure good contact between the solvent and the resveratrol - containing material.

- After that, the mixture is left to stand for a certain period to allow for the extraction of resveratrol into the solvent.

- Finally, the solvent containing resveratrol is separated from the solid residue, usually by filtration or centrifugation.

Advantages:

- It is a relatively simple and straightforward method.

- It can be carried out with relatively inexpensive equipment.

Disadvantages:

- The use of organic solvents may pose safety risks due to their flammability and toxicity.

- The extraction efficiency may not be as high as some modern methods.

- There may be co - extraction of other unwanted compounds, which requires further purification steps.

2.2 Maceration

Principle: Maceration is a simple form of solvent extraction where the raw material is soaked in a solvent for an extended period. The solvent gradually penetrates the plant material and extracts the resveratrol.

Procedure:

- The raw plant material is placed in a container, and the solvent (e.g., ethanol - water mixture) is added in sufficient quantity to completely cover the material.

- The container is sealed and left to stand at room temperature or a slightly elevated temperature for a few days to weeks. During this time, the solvent extracts the resveratrol from the plant cells.

- After the maceration period, the liquid (containing resveratrol) is separated from the solid plant material, similar to the final step in solvent extraction.

Advantages:

- It is a low - tech and cost - effective method, especially suitable for small - scale production.

Disadvantages:

- It is a time - consuming process.

- The extraction efficiency is relatively low compared to some other methods.

3. Modern Extraction Methods

3.1 Supercritical Fluid Extraction (SFE)

Principle: Supercritical fluid extraction uses a supercritical fluid, most commonly carbon dioxide (CO₂), as the extraction solvent. A supercritical fluid has properties between those of a gas and a liquid. It has a high diffusivity like a gas and a good solvent power like a liquid. When CO₂ is in its supercritical state, it can selectively extract resveratrol from the raw material.

Procedure:

- The raw material is prepared by drying and grinding as in other methods.

- The CO₂ is pressurized and heated to reach its supercritical state. The supercritical CO₂ is then passed through the raw material in an extraction vessel.

- The resveratrol is dissolved in the supercritical CO₂, and the mixture is then transferred to a separation vessel where the pressure is reduced. As the pressure drops, the CO₂ returns to its gaseous state, and the resveratrol is separated.

Advantages:

- It is a clean and environmentally friendly method as CO₂ is non - toxic, non - flammable, and can be easily removed from the final product.

- The extraction selectivity is high, which means that it can extract resveratrol more specifically, reducing the amount of co - extracted impurities.

- It can operate at relatively low temperatures, which is beneficial for heat - sensitive compounds like resveratrol.

Disadvantages:

- The equipment for supercritical fluid extraction is relatively expensive, which may limit its use in small - scale operations.

- It requires high - pressure operation, which also poses certain technical challenges and safety concerns.

3.2 Enzymatic Extraction

Principle: Enzymatic extraction utilizes specific enzymes to break down the cell walls of the raw material, thereby facilitating the release of resveratrol. Enzymes can selectively hydrolyze the components of the cell wall, such as cellulose, hemicellulose, and pectin, without affecting the resveratrol molecule.

Procedure:

- The raw material is first treated with an appropriate enzyme preparation. The enzyme is dissolved in a buffer solution, and the raw material is soaked in this enzyme solution for a certain period. For example, cellulase can be used to break down cellulose in plant cell walls.

- After the enzymatic treatment, the material is then subjected to a traditional extraction method, such as solvent extraction. The enzyme - treated material is more permeable to the solvent, and resveratrol can be more easily extracted.

Advantages:

- It is a mild extraction method that can preserve the bioactivity of resveratrol better.

- It can increase the extraction efficiency by breaking down the cell walls effectively.

Disadvantages:

- The cost of enzyme preparations can be relatively high.

- The enzymatic reaction conditions need to be carefully controlled, such as temperature, pH, and reaction time.

4. Production Process of White Resveratrol Extract

4.1 Raw Material Selection

The selection of raw materials is crucial for the production of high - quality white resveratrol extract.

- For plants rich in resveratrol, such as grapes, the variety, origin, and maturity of the grapes can significantly affect the resveratrol content. For example, red grapes, especially those from certain regions known for high - quality wine production, may have a relatively high resveratrol content.

- The quality of the raw material also includes factors such as freedom from pesticides and other contaminants. Organic - grown plants are often preferred as they are less likely to contain harmful residues.

4.2 Extraction

As discussed above, different extraction methods can be chosen depending on various factors such as cost, scale of production, and desired product quality.

- For small - scale or traditional production, solvent extraction or maceration may be more feasible. However, for large - scale and high - quality production, modern methods like supercritical fluid extraction or enzymatic extraction in combination with solvent extraction may be more appropriate.

- The extraction conditions, such as the type and concentration of the solvent (in solvent extraction), the pressure and temperature (in supercritical fluid extraction), and the enzyme type and reaction conditions (in enzymatic extraction), need to be optimized to achieve the best extraction efficiency and product quality.

4.3 Purification

After extraction, the obtained extract usually contains not only resveratrol but also other compounds. Purification is necessary to obtain a high - purity white resveratrol extract.

- One common purification method is chromatography. Column chromatography, such as silica gel chromatography or high - performance liquid chromatography (HPLC), can be used to separate resveratrol from other impurities based on differences in their chemical properties, such as polarity.

- Another method is crystallization. By carefully controlling the temperature, concentration, and other conditions, resveratrol can be crystallized out from the extract, leaving behind other impurities.

4.4 Quality Control

Quality control is an essential part of the production process of white resveratrol extract.

- One aspect of quality control is the determination of the resveratrol content. Analytical methods such as HPLC can be used to accurately measure the amount of resveratrol in the final product. The product should meet the specified resveratrol content requirements.

- Another aspect is the detection of impurities. Tests should be carried out to ensure that the product is free from harmful substances such as heavy metals, pesticides, and other organic contaminants.

- Stability testing is also important. The white resveratrol extract should be stable under different storage conditions, such as temperature and humidity. This helps to ensure the shelf - life and effectiveness of the product.

5. Conclusion

The extraction technology and production process of white resveratrol extract are complex and require careful consideration of various factors. Traditional extraction methods have their advantages in terms of simplicity and cost - effectiveness, while modern methods offer higher extraction efficiency and product quality. The production process involves multiple steps from raw material selection to quality control. Understanding these aspects is crucial for industries aiming to produce high - quality white resveratrol extract products, which can then be used in various applications in the fields of nutraceuticals, pharmaceuticals, and cosmetics.

FAQ:

What are the traditional extraction methods of white resveratrol extract?

Traditional extraction methods of white resveratrol extract include solvent extraction. Solvent extraction involves using solvents like ethanol or methanol to dissolve resveratrol from plant materials. The plant material is soaked in the solvent, and then the solvent containing resveratrol is separated from the solid residue through filtration or other means.

How does supercritical fluid extraction work for white resveratrol extract?

Supercritical fluid extraction for white resveratrol extract utilizes a supercritical fluid, often carbon dioxide. Supercritical carbon dioxide has properties between those of a gas and a liquid. It can penetrate plant cells effectively. The pressure and temperature are adjusted to a supercritical state. Resveratrol is then selectively extracted from the plant material as the supercritical fluid passes through it. After that, the pressure is reduced to separate the resveratrol - rich extract from the supercritical fluid.

What is the role of enzymatic extraction in obtaining white resveratrol extract?

Enzymatic extraction plays an important role in getting white resveratrol extract. Enzymes are used to break down the cell walls of plant materials. This helps to release resveratrol more efficiently compared to some other methods. Specific enzymes target the structural components of the plant cell walls, making the resveratrol more accessible for extraction.

What are the key steps in the purification of white resveratrol extract?

The key steps in the purification of white resveratrol extract often include filtration to remove large particles and impurities. Chromatography techniques may also be used. For example, column chromatography can separate resveratrol from other compounds based on their different affinities to the stationary and mobile phases. Crystallization is another method where pure resveratrol crystals can be formed by carefully controlling the conditions such as temperature and concentration.

How is quality control carried out during the production of white resveratrol extract?

During the production of white resveratrol extract, quality control is carried out in multiple ways. Firstly, the raw materials are inspected for their quality and authenticity. During the extraction process, parameters such as temperature, pressure (in the case of supercritical fluid extraction), and solvent concentration (in solvent extraction) are monitored. The purity of the final extract is determined using techniques like high - performance liquid chromatography (HPLC). Microbiological tests are also conducted to ensure the absence of harmful microorganisms.

Related literature

- Optimization of Resveratrol Extraction from Grape Skins"

- "Advanced Extraction Technologies for Bioactive Compounds: Resveratrol as a Case Study"

- "Quality Assurance in the Production of Resveratrol - Rich Extracts"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

100% Organic Calendula Extract.

2024-11-28

-

Wholesale Mulberry Leaf Extract Suppliers.

2024-11-28

-

China Aguaje Extract Powder Factory.

2024-11-28

-

Mulberry Extract Suppliers.

2024-11-28

-

Active components in aguaje extract.

2024-11-28

-

Standard - process cocoa extract.

2024-11-28

-

Resveratrol extract

2024-11-28

-

Black Pepper Extract

2024-11-28

-

American Ginseng Root Extract

2024-11-28

-

Gynostemma pentaphyllum extract

2024-11-28

-

Tinospora cordifolia extract

2024-11-28

-

Hedyotis Diffusa Extract

2024-11-28

-

Cranberry Extract

2024-11-28

-

Clove Powder

2024-11-28

-

Elderberry Extract

2024-11-28

-

Coconut Water Powder

2024-11-28