- 0086-571-85302990

- sales@greenskybio.com

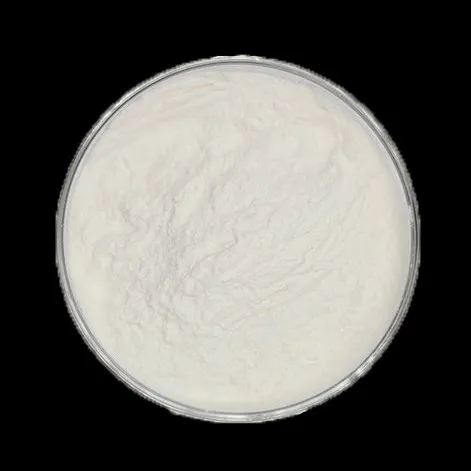

Garcinia cambogia extract manufacturer.

2024-11-29

1. Introduction

The production of Garcinia Cambogia Extract is a complex process, and the manufacturers involved are integral to its success. Garcinia Cambogia Extract has gained significant popularity in the supplement market due to its potential health benefits. Manufacturers play a vital role in ensuring the quality, safety, and effectiveness of this extract.

2. Fruit Selection

Manufacturers begin by carefully selecting the garcinia cambogia fruit. This selection process is based on multiple factors:

2.1 Genetic Variety

Different genetic varieties of the fruit may have varying levels of hydroxycitric acid (HCA). Manufacturers aim to source those with higher HCA content as HCA is considered one of the key active compounds in Garcinia Cambogia Extract. Higher HCA levels are often associated with potentially greater effectiveness in areas such as weight management.

2.2 Environmental Factors

The environmental factors of the growing regions also play a crucial role. For example:

- Soil Quality: The composition of the soil can influence the nutrient uptake of the fruit. Fruits grown in nutrient - rich soils may have a more favorable chemical composition.

- Altitude: Altitude can affect the growth and development of the garcinia cambogia fruit. Different altitudes may lead to differences in the levels of bioactive compounds in the fruit.

3. Extraction Methods

When it comes to extraction, manufacturers have a range of options:

3.1 Traditional Solvent - Based Extraction

Traditional solvent - based extraction methods are common. These methods typically involve using solvents such as ethanol or methanol to extract the active compounds from the garcinia cambogia fruit. However, one of the drawbacks of these methods is that they may leave behind some solvent residues in the final extract, which may require additional purification steps.

3.2 Supercritical CO2 Extraction

More environmentally friendly and advanced methods like supercritical CO2 extraction are also being adopted. This method offers several advantages:

- Better Selectivity: It can selectively extract the desired compounds, resulting in a purer extract with fewer impurities compared to traditional solvent - based methods.

- Environmentally Friendly: Since carbon dioxide is used as the extraction solvent, it is a more sustainable option as it is non - toxic and can be easily recycled.

Manufacturers must also optimize the extraction conditions, such as temperature and pressure, to ensure the integrity of the active compounds. Incorrect extraction conditions may lead to the degradation of HCA or other important bioactive substances.

4. Safety and Quality Assurance

One of the most important responsibilities of garcinia cambogia extract manufacturers is safety and quality. They must ensure that the extract is free from harmful substances, including heavy metals and pesticides.

4.1 Pre - extraction Testing

To achieve this, they implement strict quality control procedures. This involves pre - extraction testing of the raw materials. Tests may include:

- Heavy Metal Analysis: To check for the presence of metals such as lead, mercury, and cadmium, which can be toxic if present in high levels.

- Pesticide Residue Testing: To ensure that the fruits have not been exposed to excessive pesticides during cultivation.

4.2 Post - extraction Analysis

Post - extraction analysis of the final product is also essential. This may involve:

- HCA Content Determination: To ensure that the extract contains the appropriate amount of HCA as claimed on the product label.

- Impurity Screening: To check for any other unwanted substances that may have been introduced during the extraction process.

5. Product Development

In addition to production, manufacturers are involved in product development.

5.1 Bioavailability Improvement

They research ways to improve the bioavailability of the extract. For example:

- Encapsulation: Developing new delivery systems such as encapsulation. Encapsulated garcinia cambogia extract can protect the active ingredients from degradation in the digestive tract and enhance their absorption in the body. This can increase the effectiveness of the product as more of the active ingredients are able to reach the target sites in the body.

5.2 Formulation Innovation

Manufacturers also explore different formulations of the extract. They may combine garcinia cambogia extract with other complementary ingredients to enhance its overall effect. For instance, combining it with ingredients that can improve metabolism or reduce appetite can create a more comprehensive supplement for weight management.

6. Consumer Information Provision

Finally, manufacturers play a significant role in providing information about garcinia cambogia extract to consumers.

6.1 Potential Benefits

They need to communicate accurate and evidence - based information regarding the potential benefits of the extract. For example:

- Weight Management: Some studies suggest that garcinia cambogia extract may assist in weight loss by inhibiting the enzyme that converts carbohydrates into fat and by increasing serotonin levels, which can help reduce appetite.

- Metabolic Support: It may also play a role in improving metabolic function, although more research is needed to fully understand these mechanisms.

6.2 Proper Usage

Manufacturers should also inform consumers about the proper usage of the product. This includes details such as:

- Dosage: Recommending the appropriate dosage based on scientific research and regulatory guidelines. Taking too much or too little of the extract may not yield the desired results.

- Timing: Advising on the best time to take the supplement, such as before meals for better appetite suppression.

6.3 Possible Side Effects

It is equally important to communicate possible side effects. Although garcinia cambogia extract is generally considered safe for most people, some individuals may experience:

- Gastrointestinal Discomfort: Such as nausea, diarrhea, or abdominal pain in some cases.

- Allergic Reactions: In rare cases, allergic reactions may occur, especially in individuals with known sensitivities to plants in the Garcinia family.

By providing this comprehensive information, manufacturers help consumers make informed decisions and build trust in the product.

7. Conclusion

In summary, garcinia cambogia extract manufacturers are multi - faceted entities that are crucial for the production, quality, and promotion of this popular supplement extract. Their attention to fruit selection, extraction methods, safety and quality assurance, product development, and consumer information provision all contribute to the overall success and reputation of garcinia cambogia extract in the supplement market.

FAQ:

What are the main factors considered by garcinia cambogia extract manufacturers when selecting the fruit?

Manufacturers consider multiple factors when selecting the garcinia cambogia fruit. These include the genetic variety of the fruit, as different varieties may have different levels of hydroxycitric acid (HCA), and they aim to source fruits with higher HCA content. They also take into account environmental factors of the growing regions such as soil quality and altitude, since these can affect the fruit's chemical composition.

What extraction methods are used by garcinia cambogia extract manufacturers?

Manufacturers have several extraction methods at their disposal. Traditional solvent - based extraction methods are commonly used. However, more environmentally friendly and advanced methods like supercritical CO2 extraction are also being adopted. The supercritical CO2 extraction method has advantages such as better selectivity, which results in a purer extract with fewer impurities.

How do garcinia cambogia extract manufacturers ensure safety and quality?

Manufacturers ensure safety and quality by implementing strict quality control procedures. This includes pre - extraction testing of the raw materials to check for harmful substances like heavy metals and pesticides. They also conduct post - extraction analysis of the final product to ensure it is free from such contaminants.

What role do manufacturers play in product development of garcinia cambogia extract?

Manufacturers play an important role in product development. They research ways to enhance the bioavailability of the extract. For example, they develop new delivery systems like encapsulation. This can improve the absorption of the active ingredients in the body, thereby increasing the effectiveness of the product.

How do manufacturers provide information to consumers about garcinia cambogia extract?

Manufacturers need to communicate accurate and evidence - based information to consumers regarding the potential benefits, proper usage, and possible side effects of garcinia cambogia extract. This helps consumers make informed decisions and builds trust in the product.

Related literature

- Garcinia cambogia: A Review of Its Effects on Weight Loss and Metabolism"

- "The Production and Quality Control of Garcinia cambogia Extract in the Supplement Industry"

- "Bioavailability Enhancement of Garcinia cambogia Extract: Manufacturers' Approaches"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

Organic Mango - Flavored Powder Factory.

2024-11-29

-

Ivy Extract

2024-11-29

-

Pueraria Lobata Extract

2024-11-29

-

Saponin Extract

2024-11-29

-

Konjac Powder

2024-11-29

-

White mustard seed extract

2024-11-29

-

Curcuma Longa Extract

2024-11-29

-

Dan Shen Root Extract/Salvia Root Extract

2024-11-29

-

Red Wine Extract

2024-11-29

-

Yellow Pine Extract

2024-11-29

-

Hericium erinaceus extract powder

2024-11-29