- 0086-571-85302990

- sales@greenskybio.com

How to Extract Eucommia ulmoides Extract by Steam Distillation.

2024-11-30

1. Introduction

Eucommia ulmoides is a valuable plant with a wide range of potential applications in medicine, health products, and cosmetics. Steam distillation is an effective method for extracting its active components. Understanding the process of extracting Eucommia Ulmoides Extract by steam distillation is of great significance for maximizing the utilization of this plant resource.

2. Raw Material Preparation

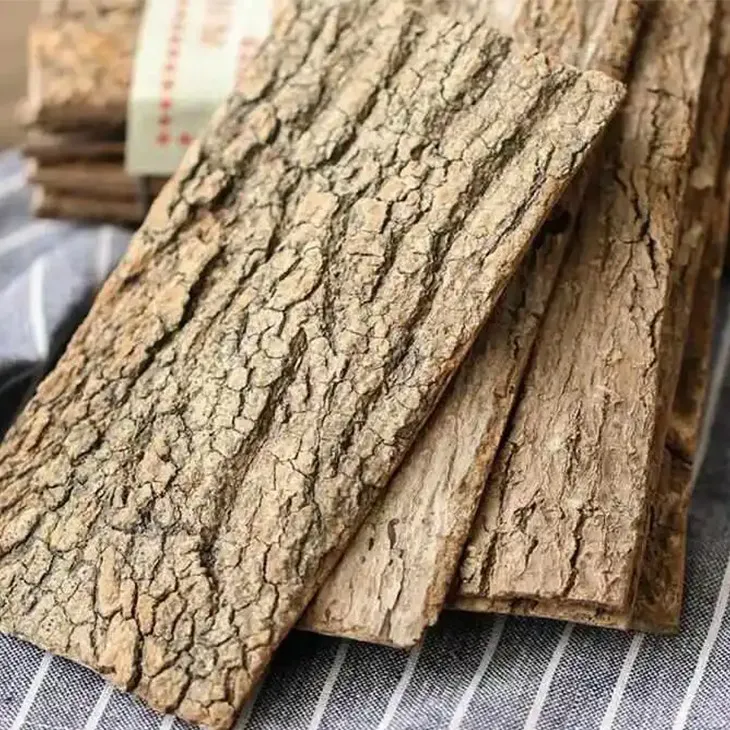

2.1. Collection of Eucommia ulmoides

The first step in raw material preparation is the proper collection of Eucommia ulmoides. It is crucial to select the appropriate time for collection. Generally, the best time is during the growth period when the plant contains a relatively high content of active ingredients. The parts of the plant that are often used for extraction include the bark, leaves, etc.2.2. Pretreatment

After collection, the raw materials need to be pretreated.- Cleaning: The collected Eucommia ulmoides should be thoroughly cleaned to remove dirt, dust, and other impurities. This can be done by gently washing with clean water.

- Drying: Drying is an essential step. It helps to reduce the moisture content in the raw materials, which is beneficial for subsequent extraction. The drying process should be carried out at an appropriate temperature and humidity to avoid the destruction of active ingredients. Usually, a drying temperature of around 40 - 60°C is suitable.

- Grinding: Once dried, the Eucommia ulmoides can be ground into a suitable particle size. A finer powder can increase the contact area between the raw materials and steam during distillation, thus improving the extraction efficiency.

3. Principle of Steam Distillation

Steam distillation is based on the principle that the vapor pressure of a mixture of two immiscible liquids (in this case, the active ingredients in Eucommia ulmoides and water) is equal to the sum of the vapor pressures of the individual components at a given temperature.

- When steam is introduced into the system containing the ground Eucommia ulmoides, the steam heats up the raw materials. As the temperature rises, the active ingredients in Eucommia ulmoides, which have certain volatility, start to vaporize along with the steam.

- The vapor mixture of the active ingredients and steam then passes through a condenser. In the condenser, the vapor is cooled and condensed back into a liquid state. Since the active ingredients are immiscible with water, they can be separated from the water phase relatively easily.

4. Detailed Operation Steps

4.1. Setup of the Steam Distillation Apparatus

- Select an appropriate steam distillation apparatus. It usually consists of a distillation flask, a condenser, a receiving flask, and a steam generator.

- Ensure that all the components are properly connected. Check for any leaks in the connections to prevent the loss of steam and vapor during the distillation process.

4.2. Loading of Raw Materials

- Place the pretreated and ground Eucommia ulmoides powder into the distillation flask. The amount of raw materials should be appropriate, not too much to avoid clogging the flask or too little to ensure sufficient extraction.

- Add a certain amount of water to the distillation flask. The ratio of raw materials to water can affect the extraction efficiency. Generally, a ratio of 1:5 - 1:10 (raw materials: water) can be used as a starting point and adjusted according to actual needs.

4.3. Start of Steam Distillation

- Turn on the steam generator to start generating steam. The steam is then introduced into the distillation flask containing the Eucommia ulmoides and water mixture.

- Control the rate of steam introduction. A too - fast steam flow rate may cause splashing of the raw materials, while a too - slow rate may lead to inefficient extraction. A moderate steam flow rate is usually recommended.

- As the steam heats the mixture, the temperature in the distillation flask gradually rises. Monitor the temperature during the process. The distillation temperature usually ranges from 100 - 150°C, depending on the nature of the active ingredients and the pressure in the system.

4.4. Condensation and Collection

- The vapor mixture of the active ingredients and steam rises from the distillation flask and enters the condenser. In the condenser, the vapor is cooled by circulating cold water, and it condenses back into a liquid state.

- The condensed liquid, which contains the Eucommia Ulmoides Extract and water, is collected in the receiving flask. The receiving flask should be placed at a proper position to ensure smooth collection.

4.5. Separation of the Extract

- Since the Eucommia Ulmoides Extract is immiscible with water, it can be separated by using a separating funnel. Pour the collected liquid from the receiving flask into the separating funnel.

- Allow the mixture to stand for a while until the two phases are clearly separated. The lower water phase can be drained out, and the upper Eucommia ulmoides extract phase can be collected.

5. Factors Affecting the Extraction Efficiency

5.1. Raw Material Characteristics

- The quality and variety of Eucommia ulmoides can significantly affect the extraction efficiency. Different varieties may have different contents of active ingredients. High - quality raw materials with a high content of target active ingredients are more likely to yield a high - quality extract.

- The particle size of the ground raw materials also plays a role. As mentioned before, a finer particle size can increase the contact area with steam, facilitating the vaporization of active ingredients.

5.2. Steam Parameters

- The steam flow rate is an important factor. An optimal steam flow rate can ensure sufficient heat transfer and mass transfer during distillation. If the steam flow rate is too high or too low, it will reduce the extraction efficiency.

- The steam temperature also affects the extraction. A higher steam temperature can accelerate the vaporization of active ingredients, but if it is too high, it may cause the decomposition of some active ingredients. Therefore, it is necessary to control the steam temperature within an appropriate range.

5.3. Distillation Time

- The length of the distillation time can influence the extraction efficiency. A too - short distillation time may result in incomplete extraction of active ingredients, while a too - long time may cause unnecessary energy consumption and may also lead to the degradation of some components. Determining the appropriate distillation time requires considering factors such as the type of raw materials and the desired extraction yield.

5.4. Ratio of Raw Materials to Water

- The ratio of Eucommia ulmoides raw materials to water can affect the extraction efficiency. An appropriate ratio can ensure good solubility and mass transfer of active ingredients. If the ratio is not appropriate, it may lead to incomplete extraction or excessive dilution of the extract.

6. Conclusion

Steam distillation is a viable method for extracting Eucommia ulmoides extract. By carefully preparing the raw materials, understanding the principle of steam distillation, following the detailed operation steps, and controlling the factors affecting the extraction efficiency, it is possible to obtain high - quality Eucommia ulmoides extracts. These extracts can then be further utilized in various fields such as medicine, health products, and cosmetics, bringing more benefits to human health and related industries.

FAQ:

What are the necessary preparations for raw materials in steam distillation extraction of Eucommia ulmoides extract?

First, high - quality Eucommia ulmoides materials should be selected. The materials are usually dried and crushed into an appropriate particle size. This helps to increase the contact area with steam during the distillation process, which is beneficial for the extraction of effective components.

What is the principle of steam distillation in extracting Eucommia ulmoides extract?

The principle of steam distillation for Eucommia ulmoides extract is based on the fact that when steam is passed through the Eucommia ulmoides raw materials, the volatile components in it will vaporize together with the steam due to the relatively high temperature and pressure. These vapor - containing components are then condensed and collected, separating the target extract from the raw materials.

What are the detailed operation steps for steam distillation extraction of Eucommia ulmoides extract?

1. Place the prepared Eucommia ulmoides raw materials in the distillation device. 2. Introduce steam into the device slowly. 3. Keep the appropriate temperature and pressure during the distillation process to ensure that the volatile components are effectively vaporized. 4. The vapor - steam mixture is led into the condenser for condensation. 5. Collect the condensed liquid, which contains the Eucommia ulmoides extract.

What factors can affect the extraction efficiency of Eucommia ulmoides extract by steam distillation?

The factors include the quality and particle size of raw materials, the temperature and pressure during distillation, and the duration of distillation. High - quality and appropriately sized raw materials can enhance the extraction. Appropriate temperature and pressure can ensure the efficient vaporization of components, and a proper distillation duration is also crucial for a high - yield extraction.

What are the potential applications of Eucommia ulmoides extract obtained by steam distillation?

The Eucommia ulmoides extract obtained by steam distillation has potential applications in medicine, such as in the development of drugs for treating certain diseases. In the field of health products, it can be used to produce supplements with various health - promoting functions. In cosmetics, it may be added to products for skin care, such as anti - aging and moisturizing products.

Related literature

- Study on the Chemical Components of Eucommia ulmoides Extract by Steam Distillation"

- "Optimization of Steam Distillation Process for Eucommia ulmoides Extract"

- "The Bioactivity of Eucommia ulmoides Extract Obtained by Steam Distillation"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

The best lemon juice powder in nature.

2024-11-30

-

Organic Vitamin K2 Powder Suppliers

2024-11-30

-

Bulk purchase of L - tyrosine.

2024-11-30

-

Vitamin K2 Manufacturers

2024-11-30

-

100% Pure Natural Rutin.

2024-11-30

-

Chinese Citrus Bioflavonoid Suppliers.

2024-11-30

-

Carrageenan Extract Powder

2024-11-30

-

Uridine-5'-monophosphate Disodium salt

2024-11-30

-

Plantain extract

2024-11-30

-

Pueraria Lobata Extract

2024-11-30

-

Lemon Extract

2024-11-30

-

Yohimbine Bark Extract

2024-11-30

-

Ginseng Root Extract

2024-11-30

-

Curcuma Longa Extract

2024-11-30

-

Phyllanthus Emblica Extract

2024-11-30

-

Sophora Japonica Flower Extract

2024-11-30