- 0086-571-85302990

- sales@greenskybio.com

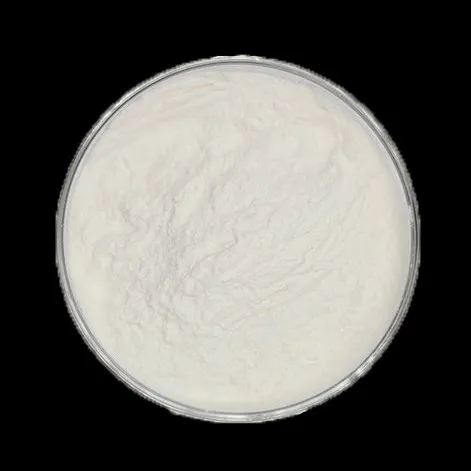

How to make powder from garcinia cambogia extract.

2024-12-01

1. Introduction

Garcinia Cambogia Extract has gained significant popularity in recent years due to its potential health benefits, particularly in relation to weight management. Making powder from this extract can be a useful way to create a more convenient and versatile product form. This article will explore the various aspects involved in the process, from raw material selection to quality control.

2. Raw Material Selection

2.1 Source of Garcinia Cambogia

It is crucial to start with high - quality Garcinia cambogia fruits. The fruits should be sourced from reliable growers. Ideally, they should be organically grown to avoid potential contamination from pesticides and other chemicals. Fruits from regions known for their favorable growing conditions for Garcinia cambogia, such as certain parts of Southeast Asia, are often preferred.

2.2 Purity of the Extract

When obtaining the Garcinia Cambogia Extract, it is essential to ensure its purity. The extract should be free from impurities such as other plant materials that may have been co - extracted accidentally. Look for extracts with a high percentage of hydroxycitric acid (HCA), which is the main active component in Garcinia cambogia. A purity level of at least 50% HCA is often considered good for making high - quality powder.

3. Equipment Needed

3.1 Drying Equipment

- A dehydrator is a great option for drying the Garcinia Cambogia Extract. It allows for controlled drying at relatively low temperatures, which helps to preserve the active components. Set the dehydrator to a temperature between 40 - 50°C. This slow drying process can take several hours to a day, depending on the quantity of the extract.

- An oven can also be used if a dehydrator is not available. However, it is important to use a low - temperature setting, typically around 50 - 60°C. Keep a close eye on the extract while it is drying in the oven to prevent over - drying or burning.

3.2 Grinding Equipment

- A coffee grinder can be used for small - scale grinding of the dried Garcinia cambogia extract. It is convenient and easy to operate. However, it may not be suitable for large - quantity production as it has a relatively small capacity.

- For larger - scale production, a industrial - grade grinder is recommended. These grinders can handle larger volumes of the dried extract and can produce a more uniform powder. They are often adjustable to achieve different levels of fineness in the powder.

4. The Process of Making Powder

4.1 Drying the Extract

- First, spread the Garcinia cambogia extract evenly on the drying trays of the dehydrator or in a baking dish if using an oven. Make sure that the layer of the extract is not too thick; a thickness of about 1 - 2 centimeters is ideal.

- As mentioned earlier, set the appropriate temperature and start the drying process. Stir the extract occasionally during drying to ensure even drying. This helps to prevent the formation of lumps or uneven drying.

- Once the extract has dried completely, it should have a brittle texture. It is important to ensure that there is no remaining moisture, as this can affect the quality and shelf - life of the final powder.

4.2 Grinding the Dried Extract

- Place the dried Garcinia cambogia extract into the chosen grinding device. If using a coffee grinder, fill it to an appropriate level, not overloading it to ensure effective grinding.

- Grind the extract until it reaches the desired fineness. For a more fine - textured powder, run the grinder for a longer period. However, be careful not to over - grind, which can cause the powder to become too fine and potentially affect its flowability.

- After grinding, transfer the powder to a clean, dry container for further processing or storage.

5. Quality Control Measures

5.1 Testing for Purity

- Conduct chemical analysis to verify the purity of the powder. This can include tests for the presence of HCA and the absence of contaminants. High - performance liquid chromatography (HPLC) is a commonly used method for accurately determining the HCA content in the powder.

- Check for any signs of adulteration, such as the presence of fillers or other substances that are not supposed to be in the Garcinia cambogia powder. This can be done through various spectroscopic and chromatographic techniques.

5.2 Assessing Particle Size

- Use a particle size analyzer to determine the size distribution of the powder particles. A consistent particle size is important for ensuring the powder's flowability, solubility, and overall quality. The ideal particle size for Garcinia cambogia powder can vary depending on its intended use, but generally, a relatively fine and uniform size is preferred.

- If the particle size is not within the desired range, adjustments can be made to the grinding process. For example, if the particles are too large, the grinding time can be increased or a different grinder with a finer grinding setting can be used.

5.3 Microbial Testing

- Perform microbial tests to check for the presence of bacteria, fungi, and other microorganisms. This is especially important as the powder may be used for consumption. Tests for total viable count, yeast, and mold should be carried out according to standard microbiological methods.

- If microbial contamination is detected, steps should be taken to identify the source of the contamination and to correct the production process. This may involve improving the hygiene of the production area, sterilizing the equipment more thoroughly, or ensuring proper storage conditions for the raw materials.

6. Packaging and Storage

6.1 Packaging Materials

- Use airtight containers for packaging the Garcinia cambogia powder. This helps to prevent moisture absorption and oxidation, which can degrade the quality of the powder over time. Dark - colored containers, such as amber glass bottles or opaque plastic containers, are preferred as they can protect the powder from light exposure.

- Consider using desiccant packets inside the containers. These packets can absorb any remaining moisture and further protect the powder from spoilage. Make sure that the desiccant packets are food - grade and do not contaminate the powder.

6.2 Storage Conditions

- Store the packaged Garcinia cambogia powder in a cool, dry place. A temperature range of 15 - 25°C is ideal. Avoid storing the powder in areas with high humidity, such as bathrooms or basements.

- Keep the powder away from direct sunlight and sources of heat. Exposure to sunlight can cause chemical degradation of the active components in the powder, and heat can accelerate the oxidation process.

7. Conclusion

Making powder from Garcinia cambogia extract involves careful consideration of raw material selection, proper use of equipment, and strict quality control measures. By following these steps, it is possible to produce a high - quality Garcinia cambogia powder that can be used for various purposes, such as in dietary supplements or for research purposes. However, it is important to note that the production should be carried out in compliance with relevant regulations and safety standards to ensure the safety and efficacy of the final product.

FAQ:

Q1: What are the key factors in raw material selection for making powder from garcinia cambogia extract?

When selecting raw materials for making garcinia cambogia extract powder, several factors are crucial. Firstly, the source of the garcinia cambogia should be reliable. It is best to choose from regions where the plant is known to grow well and is free from contaminants. High - quality, fresh garcinia cambogia fruits are preferred as they are likely to contain more active compounds. Also, ensure that the raw materials are free from pesticides, heavy metals, and other harmful substances. This can be verified through proper testing methods. Additionally, the ripeness of the fruits can affect the quality of the extract powder, so fruits at the appropriate stage of ripeness should be selected.

Q2: What kind of equipment is needed to make powder from garcinia cambogia extract?

To make powder from garcinia cambogia extract, several types of equipment are required. Firstly, extraction equipment such as a Soxhlet extractor or a modern supercritical fluid extraction device can be used to extract the active compounds from the garcinia cambogia. After extraction, a drying device like a spray dryer or a freeze - dryer is necessary to remove the moisture and convert the extract into a powder form. Grinding equipment, such as a high - speed grinder, is also needed to ensure that the dried extract is ground into a fine powder. Additionally, filtration equipment can be used during the extraction process to remove impurities.

Q3: How can we ensure quality control during the process of making garcinia cambogia extract powder?

Quality control during the production of garcinia cambogia extract powder is essential. Firstly, strict incoming raw material inspection should be carried out. This includes testing for purity, active ingredient content, and the absence of contaminants. During the extraction process, parameters such as temperature, pressure (if applicable in the extraction method), and extraction time should be carefully controlled to ensure consistent extraction of the active compounds. After extraction, the drying process should be monitored to ensure that the powder has the appropriate moisture content. Regular sampling and laboratory analysis should be done to check for the presence of any impurities, and to verify the concentration of the active ingredients. Packaging should also be done in a way that protects the powder from moisture, light, and other environmental factors.

Q4: Are there any safety precautions to be taken when making powder from garcinia cambogia extract?

Yes, there are safety precautions when making powder from garcinia cambogia extract. Workers should wear appropriate personal protective equipment, such as gloves and safety glasses, especially when handling the raw materials and during the extraction process, as some chemicals or solvents may be used. The extraction area should be well - ventilated to prevent the accumulation of fumes or vapors. Also, when using equipment, it should be operated according to the manufacturer's instructions to avoid accidents. Since garcinia cambogia extract may have potential interactions or side effects, proper handling and storage are necessary to prevent any accidental ingestion or exposure.

Q5: Can the method of making powder from garcinia cambogia extract affect its effectiveness?

Yes, the method of making powder from garcinia cambogia extract can significantly affect its effectiveness. If the extraction process is not carried out properly, for example, if the wrong solvents are used or if the extraction time and temperature are not optimal, the amount and quality of the active compounds extracted may be reduced. Similarly, during the drying and grinding processes, if the powder is over - dried or not ground finely enough, it can affect the bioavailability of the active ingredients. Therefore, following the correct and optimized production methods is crucial to ensure that the final powder retains its effectiveness.

Related literature

- Garcinia Cambogia: Properties and Potential Applications"

- "The Extraction and Utilization of Garcinia Cambogia Extract in the Pharmaceutical Industry"

- "Optimizing the Production of Garcinia Cambogia Extract Powder: A Review"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

The best lemon juice powder in nature.

2024-12-01

-

Organic Vitamin K2 Powder Suppliers

2024-12-01

-

Bulk purchase of L - tyrosine.

2024-12-01

-

Vitamin K2 Manufacturers

2024-12-01

-

100% Pure Natural Rutin.

2024-12-01

-

Chinese Citrus Bioflavonoid Suppliers.

2024-12-01

-

Golden Seal Extract

2024-12-01

-

Tinospora cordifolia extract

2024-12-01

-

Hawthorn Extract

2024-12-01

-

Calendula Extract

2024-12-01

-

Acerola Extract

2024-12-01

-

Quercetin

2024-12-01

-

Milk Thistle Extract

2024-12-01

-

Shikone Extract

2024-12-01

-

Hericium erinaceus extract powder

2024-12-01

-

Red Vine Extract

2024-12-01