- 0086-571-85302990

- sales@greenskybio.com

How to make powder with astaxanthin?

2024-12-01

1. Introduction to Astaxanthin

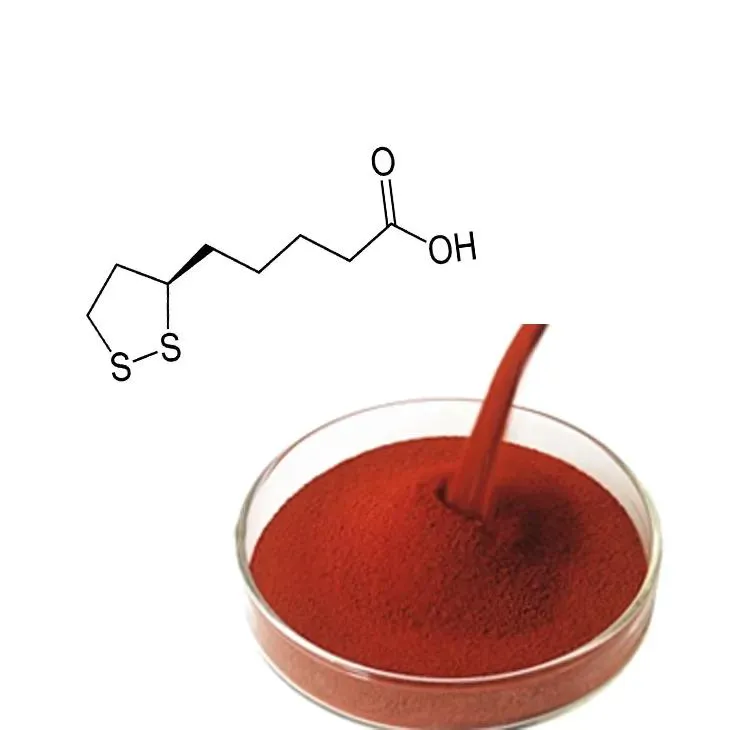

Astaxanthin is a powerful antioxidant that has gained significant attention in recent years. It is a carotenoid pigment that occurs naturally in certain algae, yeast, and marine organisms such as salmon, shrimp, and krill. Astaxanthin has a bright red color and is known for its numerous health benefits, including antioxidant, anti - inflammatory, and potential anti - aging properties.

Due to its hydrophobic nature, astaxanthin is often difficult to incorporate into various products in its natural form. Therefore, converting it into a powder form can increase its stability, solubility, and ease of use in a wide range of applications, such as dietary supplements, cosmetics, and food additives.

2. Raw Material Selection

The first step in making astaxanthin powder is to select the appropriate raw material. There are several sources of astaxanthin available:

- Natural Algae Extracts: Some species of microalgae, such as Haematococcus pluvialis, are rich sources of astaxanthin. Algae - derived astaxanthin is often considered a high - quality source as it is produced through natural photosynthesis.

- Yeast - Fermented Astaxanthin: Produced by fermenting certain yeasts, this form of astaxanthin can be a more sustainable and cost - effective option.

- Synthetic Astaxanthin: Although synthetic astaxanthin is available, it may not have the same complex composition and potential health benefits as natural sources. However, it can be a more affordable option for some industrial applications.

When choosing the raw material, factors such as purity, cost, and intended use of the astaxanthin powder should be considered. For example, if the powder is intended for use in high - end dietary supplements, a natural and pure source of astaxanthin may be preferred.

3. Extraction of Astaxanthin

Once the raw material is selected, the next step is to extract astaxanthin. The extraction process depends on the source of astaxanthin:

3.1. Algae - Based Extraction

- Cultivation: First, the microalgae, such as Haematococcus pluvialis, need to be cultivated. This typically involves providing the appropriate growth conditions, including light, temperature, and nutrient - rich media.

- Harvesting: After the algae have reached the desired growth stage, they are harvested. This can be done through centrifugation or filtration methods to separate the algae from the growth medium.

- Cell Disruption: To release the astaxanthin from the algal cells, cell disruption techniques are employed. This can include mechanical methods such as homogenization or bead - milling, or non - mechanical methods like enzymatic digestion or osmotic shock.

- Solvent Extraction: Once the cells are disrupted, a suitable solvent is used to extract the astaxanthin. Organic solvents such as hexane, acetone, or ethyl acetate are commonly used. However, it is important to ensure that the solvent is of food - grade or pharmaceutical - grade quality if the astaxanthin is intended for human consumption or use in supplements.

3.2. Yeast - Fermented Astaxanthin Extraction

- Fermentation Termination: When the yeast has completed the fermentation process and produced astaxanthin, the fermentation is terminated. This can be achieved by adjusting the pH, temperature, or adding certain chemicals to stop the yeast's metabolic activity.

- Separation: The yeast cells are then separated from the fermentation broth. Centrifugation or filtration can be used for this purpose.

- Extraction: Similar to the algae - based extraction, a solvent extraction method may be employed to extract the astaxanthin from the yeast cells. However, the extraction conditions may need to be optimized based on the characteristics of the yeast - derived astaxanthin.

4. Purification of Astaxanthin

After extraction, the astaxanthin may contain impurities such as other pigments, lipids, or proteins. Purification is necessary to obtain a high - quality astaxanthin powder. There are several purification methods:

- Column Chromatography: This is a common method used to separate astaxanthin from other components based on their differential affinities for the stationary and mobile phases in a chromatography column. Different types of chromatography columns, such as silica - based or polymeric columns, can be used depending on the nature of the impurities and the astaxanthin itself.

- Crystallization: By carefully controlling the temperature, concentration, and solvent composition, astaxanthin can be crystallized out of the solution. This method can be effective in removing soluble impurities.

- Membrane Filtration: Ultrafiltration or nanofiltration membranes can be used to separate astaxanthin from larger or smaller molecules. This method is relatively simple and can be used for a preliminary purification step.

The choice of purification method depends on factors such as the scale of production, cost, and the required purity of the final astaxanthin powder. In some cases, a combination of purification methods may be used to achieve the desired level of purity.

5. Drying and Powder Formation

Once the astaxanthin has been purified, it needs to be dried to form a powder. There are different drying methods available:

- Spray Drying: This is a commonly used method in the food and pharmaceutical industries. In spray drying, the purified astaxanthin solution is sprayed into a hot air stream. The water or solvent evaporates quickly, leaving behind fine astaxanthin particles. Spray drying can produce powders with good flowability and solubility properties. However, it requires careful control of parameters such as inlet air temperature, feed rate, and atomizer pressure to ensure product quality.

- Freeze Drying: Also known as lyophilization, freeze drying involves freezing the astaxanthin solution first and then subjecting it to a vacuum to remove the ice (water) by sublimation. Freeze - dried astaxanthin powder has a high porosity and can retain its bioactivity well. However, it is a more expensive and time - consuming process compared to spray drying.

- Vacuum Drying: In vacuum drying, the astaxanthin is dried under reduced pressure. This method can be used when a relatively mild drying condition is required to avoid degradation of the astaxanthin. Vacuum drying can also help in removing solvents more effectively compared to normal drying methods.

After drying, the resulting astaxanthin powder may need to be further processed, such as milling or sieving, to achieve the desired particle size and powder characteristics. For example, milling can break down any agglomerates of powder particles, while sieving can remove any oversized or undersized particles.

6. Quality Control and Characterization

To ensure the quality of the astaxanthin powder, several quality control measures and characterization techniques are employed:

- Purity Analysis: High - performance liquid chromatography (HPLC) is often used to determine the purity of astaxanthin in the powder. HPLC can separate and quantify astaxanthin from other components, providing accurate information about its purity level.

- Identification of Isomers: Astaxanthin has different isomers, and it is important to identify and quantify them. Spectroscopic techniques such as nuclear magnetic resonance (NMR) or infrared spectroscopy (IR) can be used to distinguish between different isomers of astaxanthin.

- Stability Testing: The stability of the astaxanthin powder under different storage conditions (e.g., temperature, light, and humidity) is evaluated. This can involve long - term storage studies and accelerated stability tests to predict the shelf - life of the powder.

- Bioavailability Studies: If the astaxanthin powder is intended for use in dietary supplements or pharmaceuticals, bioavailability studies may be conducted. These studies assess how well the astaxanthin is absorbed and utilized by the body.

In addition to these quality control measures, the powder's physical characteristics such as particle size distribution, bulk density, and flowability should also be characterized to ensure its suitability for different applications.

7. Packaging and Storage

The final step in making astaxanthin powder is packaging and storage.

- Packaging: The astaxanthin powder should be packaged in a suitable material to protect it from environmental factors such as light, moisture, and oxygen. Dark - colored, airtight containers are often preferred. For example, amber - colored glass bottles or laminated aluminum foil pouches can be used.

- Storage: The powder should be stored in a cool, dry, and dark place. The ideal storage temperature is usually between 2 - 8°C. Proper storage conditions are crucial to maintain the stability and quality of the astaxanthin powder over time.

FAQ:

What are the main raw materials needed to make astaxanthin powder?

The main raw material is astaxanthin itself, which can be sourced from natural producers like certain algae (such as Haematococcus pluvialis) or synthetically produced. Additionally, carriers or excipients may be required depending on the method of powder formation. These can include substances like maltodextrin or other food - grade additives to help with the drying process and to improve the powder's flowability and stability.

What are the different methods to make astaxanthin powder?

One common method is spray drying. In this process, astaxanthin is first dissolved or dispersed in a suitable solvent, often along with a carrier material. The solution is then sprayed into a hot drying chamber where the solvent evaporates quickly, leaving behind the astaxanthin powder. Another method is freeze - drying, which involves freezing the astaxanthin - containing solution and then subjecting it to a vacuum to sublime the ice, resulting in a powder. There is also the option of using milling techniques to reduce astaxanthin - rich materials into a fine powder form, although this may require prior processing to ensure proper dispersion.

How can the quality of astaxanthin powder be ensured during the production process?

To ensure quality, strict control of the raw materials is crucial. The source of astaxanthin should be well - characterized and of high purity. During the production process, parameters such as temperature, pressure (in case of drying methods), and mixing ratios need to be carefully monitored. For example, in spray drying, the inlet and outlet temperatures should be optimized to prevent degradation of astaxanthin. Additionally, proper handling and storage conditions post - production, such as protection from light, heat, and moisture, are essential to maintain the powder's quality.

Are there any safety precautions to be taken when making astaxanthin powder?

Yes, there are several safety precautions. When handling astaxanthin, appropriate personal protective equipment (PPE) should be used, especially if dealing with concentrated forms or during processes that may generate dust. In case of using solvents in the production process, proper ventilation is necessary to avoid inhalation of solvent vapors. Also, since astaxanthin can be sensitive to certain environmental factors, proper storage of raw materials and intermediate products to prevent contamination or degradation is important.

What are the potential applications of astaxanthin powder?

Astaxanthin powder has a wide range of applications. In the nutraceutical and dietary supplement industry, it is used for its antioxidant properties. It can also be added to cosmetics and skincare products as it may help in protecting the skin from oxidative stress and promoting skin health. In the food industry, astaxanthin powder can be used as a natural colorant for products like fish feed, to enhance the color of fish flesh, and in some functional foods and beverages.

Related literature

- Astaxanthin: Sources, Extraction, Stability, Biological Activities and Its Commercial Applications"

- "Production and Characterization of Astaxanthin - Containing Powders for Nutraceutical Applications"

- "Advances in Astaxanthin Powder Manufacturing Technologies"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

The best lemon juice powder in nature.

2024-12-01

-

Organic Vitamin K2 Powder Suppliers

2024-12-01

-

Bulk purchase of L - tyrosine.

2024-12-01

-

Vitamin K2 Manufacturers

2024-12-01

-

100% Pure Natural Rutin.

2024-12-01

-

Chinese Citrus Bioflavonoid Suppliers.

2024-12-01

-

Soy Extract

2024-12-01

-

Tinospora cordifolia extract

2024-12-01

-

Plantain extract

2024-12-01

-

Curcuma Longa Extract/Turmeric extract

2024-12-01

-

Motherwort Extract

2024-12-01

-

Astaxanthin

2024-12-01

-

Scutellaria Extract

2024-12-01

-

Coconut Water Powder

2024-12-01

-

Alisma Extract

2024-12-01

-

Oyster Mushroom Extract Powder

2024-12-01