- 0086-571-85302990

- sales@greenskybio.com

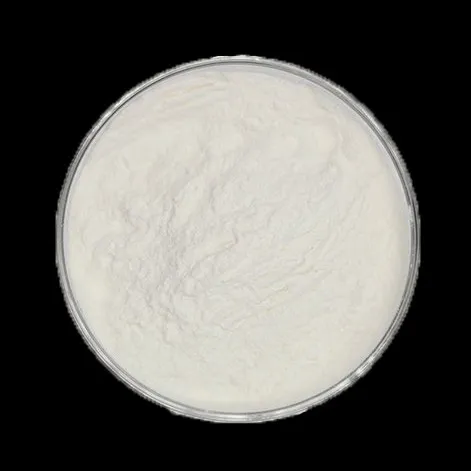

Manufacturer of Organic Saw Palmetto Extract Powder.

2024-11-30

Introduction to the Industry

The manufacturing of organic Saw Palmetto Extract powder has emerged as a significant and rapidly growing industry. Saw Palmetto Extract powder has gained considerable popularity due to its numerous potential health benefits. It is widely recognized for its role in supporting prostate health and is also believed to have positive effects on hair growth. This has led to an exponential increase in the demand for this product both in the domestic and international markets.

Botanical Knowledge Requirement

Manufacturers in this sector must possess in - depth botanical knowledge. Since they are dealing with the saw palmetto plant, understanding the plant's life cycle and characteristics is crucial.

Harvesting Time

One of the most important aspects is knowing the optimal time for harvesting. The berries of the saw palmetto plant are the main source of the extract. Harvesting at the right time ensures that the maximum amount of active ingredients can be obtained. If the berries are harvested too early or too late, the quality and quantity of the active compounds may be compromised. For example, if harvested too early, the berries may not have fully developed the necessary bioactive substances. On the other hand, if harvested too late, some of the valuable components may have started to degrade.

The Manufacturing Process

The process of converting saw palmetto berries into extract powder is a complex and multi - step procedure.

Extraction

The first step in the manufacturing process is extraction. This involves using appropriate solvents to draw out the desired components from the saw palmetto berries. The choice of solvent is critical as it can affect the purity and quality of the final extract. Commonly used solvents are carefully selected based on their ability to dissolve the active ingredients while minimizing the extraction of unwanted substances. For instance, some solvents may be more effective in extracting the fatty acids and sterols, which are among the key bioactive compounds in Saw Palmetto Extract.

Purification

After extraction, purification is carried out. This step is necessary to remove any impurities that may have been co - extracted during the previous step. Purification techniques can include filtration, chromatography, and other methods. Filtration can be used to remove solid particles, while chromatography can separate different compounds based on their chemical properties. By purifying the extract, manufacturers can ensure that the final product contains a higher concentration of the desired bioactive compounds and is free from harmful or unwanted substances.

Drying

The final step in the manufacturing process is drying. Once the extract has been purified, it needs to be dried to convert it into a fine powder. Drying can be achieved through various methods such as spray drying or freeze - drying. Spray drying involves spraying the liquid extract into a hot chamber where the water evaporates quickly, leaving behind a powder. Freeze - drying, on the other hand, involves freezing the extract first and then removing the water through sublimation. Each drying method has its own advantages and may be chosen depending on the specific requirements of the product. For example, freeze - drying may be preferred for products where the preservation of the bioactive compounds' structure is of utmost importance.

Quality Assurance

Quality assurance is a top priority for organic saw palmetto extract powder manufacturers.

Chemical Analysis

Manufacturers use state - of - the - art laboratory equipment to analyze the chemical composition of the extract powder. This includes techniques such as high - performance liquid chromatography (HPLC) and gas chromatography - mass spectrometry (GC - MS). These methods allow for the accurate quantification of the bioactive compounds present in the powder. For example, HPLC can be used to determine the amount of fatty acids, while GC - MS can be used to identify and quantify sterols. By closely monitoring the chemical composition, manufacturers can ensure that the product contains the correct amount of the necessary bioactive substances. This is crucial as the effectiveness of the saw palmetto extract powder in providing its potential health benefits is directly related to the concentration of these compounds.

Packaging Solutions

Another important aspect of quality assurance is the focus on packaging solutions. The packaging needs to be able to preserve the integrity of the powder during storage and transportation. For instance, the packaging material should be impermeable to moisture, light, and air, which can cause degradation of the powder. Manufacturers may use vacuum - sealed packaging or packaging with desiccants to prevent moisture absorption. Additionally, the packaging should be sturdy enough to protect the powder from physical damage during transportation. By ensuring proper packaging, manufacturers can guarantee that consumers receive a product of the highest quality.

Meeting Regulatory Requirements

Manufacturers of organic saw palmetto extract powder must also meet various regulatory requirements.

Organic Certification

Since the product is labeled as "organic," it must adhere to the strict standards set by organic certification bodies. These standards cover aspects such as the use of pesticides, fertilizers, and the overall farming practices of the saw palmetto plants. The manufacturing process also needs to comply with organic regulations, including the use of approved solvents and processing methods. Obtaining and maintaining organic certification is not only a legal requirement but also an important factor in building consumer trust as more and more consumers are demanding organic products.

Quality and Safety Standards

In addition to organic certification, manufacturers need to meet general quality and safety standards. This includes compliance with good manufacturing practices (GMP). GMP ensures that the manufacturing process is carried out in a clean, hygienic, and controlled environment. It also requires proper documentation of all manufacturing steps, from the sourcing of raw materials to the final packaging of the product. Meeting these standards helps to ensure the safety and quality of the saw palmetto extract powder and protects the health of consumers.

Research and Development

Continuous research and development (R & D) is essential for manufacturers in this industry.

New Extraction Methods

Research is being carried out to develop new and more efficient extraction methods. Traditional extraction methods may have limitations in terms of yield and purity. New techniques such as supercritical fluid extraction are being explored. Supercritical fluid extraction uses a fluid that is above its critical temperature and pressure, which has unique solvent properties. This method has the potential to provide higher yields of pure extract with less solvent residue, which could lead to a higher - quality product.

Enhancing Bioavailability

Another area of R & D is focused on enhancing the bioavailability of the saw palmetto extract powder. Bioavailability refers to the proportion of a drug or supplement that enters the circulation and is able to have an active effect. Manufacturers are exploring ways to modify the formulation of the powder to improve its absorption in the body. This could involve encapsulating the powder or combining it with other substances that can enhance its solubility or absorption in the digestive tract.

Market Trends and Competition

The market for organic saw palmetto extract powder is constantly evolving, and manufacturers need to be aware of the latest market trends and competition.

Consumer Preferences

Consumer preferences play a significant role in shaping the market. For example, there is an increasing demand for natural and organic products. Consumers are also more educated about the potential health benefits of different supplements and are looking for products that are backed by scientific research. Manufacturers need to respond to these preferences by offering high - quality, organic, and scientifically - validated products.

Competitive Landscape

The market for saw palmetto extract powder is highly competitive. There are numerous manufacturers both domestically and internationally. To stand out in this competitive market, manufacturers need to focus on product quality, innovation, and marketing. They need to differentiate their products by highlighting unique features such as superior extraction methods, higher bioavailability, or additional health benefits. Effective marketing strategies can also help to increase brand awareness and attract more customers.

Conclusion

The manufacturing of organic saw palmetto extract powder is a complex and dynamic industry. Manufacturers need to have a comprehensive understanding of botany, a well - controlled manufacturing process, strict quality assurance measures, compliance with regulatory requirements, and a focus on research and development. By staying attuned to market trends and competition, they can succeed in this booming industry and provide consumers with high - quality products that offer potential health benefits.

FAQ:

What are the main health benefits of organic saw palmetto extract powder?

Organic saw palmetto extract powder is mainly known for potentially supporting prostate health and hair growth. However, more research is still needed to fully understand all of its health - related effects.

How do manufacturers ensure the quality of organic saw palmetto extract powder?

Manufacturers ensure quality by using state - of - the - art laboratory equipment to analyze the chemical composition. They check for the right amount of bioactive compounds like fatty acids and sterols. Also, they focus on proper packaging to preserve the powder's integrity during storage and transportation.

Why is in - depth botany knowledge important for manufacturers?

In - depth botany knowledge is crucial because manufacturers deal with the saw palmetto plant. Understanding the optimal harvesting time of the berries is essential to obtain the maximum active ingredients.

What is the manufacturing process of organic saw palmetto extract powder?

The manufacturing process involves harvesting the berries at the right time first. Then, it includes extraction, purification, and drying to convert the berries into a fine powder.

How can consumers be sure they are getting a high - quality product?

Consumers can trust that they are getting a high - quality product if the manufacturer has a good reputation for quality assurance. This includes proper analysis of the chemical composition and appropriate packaging to maintain the powder's quality.

Related literature

- The Potential Health Benefits of Saw Palmetto Extract"

- "Saw Palmetto: From Plant to Extract - Manufacturing Insights"

- "Quality Assurance in Organic Saw Palmetto Extract Powder Production"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

High - quality Chasteberry Extract Products.

2024-11-30

-

China's banana juice powder suppliers.

2024-11-30

-

Bulk purchase of cranberry extract.

2024-11-30

-

How to make powder with bayberry extract?

2024-11-30

-

The best peony root extract in nature.

2024-11-30

-

100% Pure Organic Baicalin.

2024-11-30

-

American Ginseng Root Extract

2024-11-30

-

Giant Knotweed Extract

2024-11-30

-

Red Vine Extract

2024-11-30

-

Echinacea Extract

2024-11-30

-

Wheat Germ Extract

2024-11-30

-

Lemon Extract

2024-11-30

-

Passionflower Extract

2024-11-30

-

Dandelion Root Extract

2024-11-30

-

Maca Extract

2024-11-30

-

Oat Straw Extract Powder

2024-11-30