- 0086-571-85302990

- sales@greenskybio.com

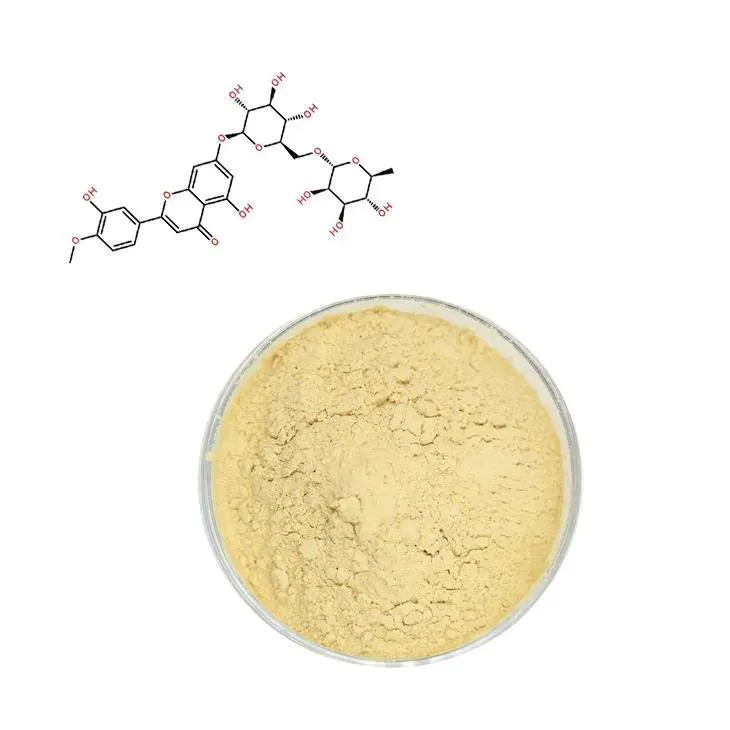

Manufacturers of Organic Diosmin Powder.

2024-11-30

Introduction

Organic Diosmin powder has emerged as a highly significant compound in multiple industries. In the pharmaceutical and nutraceutical sectors, its importance cannot be overstated. Manufacturers of this powder are at the heart of fulfilling the ever - increasing demand for this valuable substance.

The Importance of Raw Material Sourcing

1. Source of Raw Materials

The production of organic Diosmin powder begins with the sourcing of raw materials. These raw materials are typically sourced from plant origins, with citrus fruits being a common source. The quality of the raw materials directly impacts the final product.2. Ensuring Purity and Quality

Ensuring the purity and quality of these raw materials is of utmost importance. Manufacturers must carefully select and test the raw materials to guarantee that they are free from contaminants and of high quality. This is the cornerstone for the production of top - notch organic Diosmin powder.Extraction and Purification Techniques

1. Advanced Extraction

Manufacturers employ state - of - the - art extraction techniques. They use sophisticated equipment to extract Diosmin from the raw materials. This process requires precision and expertise. For example, specific solvents and extraction conditions need to be carefully controlled to ensure maximum yield and quality of the extracted Diosmin.2. Purification to Meet Standards

After extraction, the purification process is crucial. The manufacturers must purify the Diosmin to meet strict quality standards. This involves removing any impurities, such as other plant compounds or residual solvents. High - quality purification not only requires advanced technology but also a well - trained workforce.Quality Control in the Manufacturing Process

1. Comprehensive Testing

Quality control is a vital aspect of the manufacturing process. Manufacturers need to conduct comprehensive tests at every stage of production.- They check for chemical purity, ensuring that the Diosmin powder contains only the desired compound and no unwanted substances.

- Testing for potency is also essential. The powder must have the correct level of activity for its intended applications in the pharmaceutical and nutraceutical fields.

- The absence of contaminants, such as heavy metals or pesticides, is strictly monitored.

2. Adhering to Quality Standards

Only by strictly adhering to quality control measures can manufacturers produce organic Diosmin powder that is safe and effective for various applications. This is not only important for the end - users' health but also for the reputation of the manufacturers in the market.Sustainable Production Practices

1. Waste Reduction

Many organic Diosmin powder manufacturers are committed to sustainable production. They strive to reduce waste generated during the production process. This can be achieved through optimizing production processes, for example, by recycling solvents or reusing by - products where possible.2. Energy Conservation

Energy conservation is another key focus area. Manufacturers may invest in energy - efficient equipment or modify their production processes to reduce energy consumption. This not only helps in reducing the production cost but also has a positive impact on the environment.3. Minimizing Environmental Impact

By implementing sustainable practices, manufacturers can minimize the environmental impact of their production processes. This meets the increasing demand from consumers for sustainable products and also helps in fulfilling corporate social responsibility.The Global Market of Organic Diosmin Powder Manufacturers

1. Manufacturers with Large - scale Production Capabilities

In the global market, there are numerous manufacturers of organic Diosmin powder. Some are known for their large - scale production capabilities. These manufacturers can produce large quantities of the powder to meet the high - volume demands of the market. They often have advanced production facilities and a well - organized supply chain to ensure timely delivery of their products.2. Manufacturers of High - quality, Niche - market Products

On the other hand, there are manufacturers that are renowned for their high - quality, niche - market products. These manufacturers focus on producing specialized forms of organic Diosmin powder, perhaps with higher purity levels or for specific applications. They target a more selective customer base, such as high - end pharmaceutical companies or specialized nutraceutical product manufacturers.Conclusion

Overall, manufacturers of organic Diosmin powder play a significant role in the availability and application of this compound in different fields. Through their efforts in raw material sourcing, extraction, purification, quality control, and sustainable production, they contribute to the growth and development of the organic Diosmin powder market.

FAQ:

What are the main sources of raw materials for organic Diosmin powder manufacturers?

The main sources of raw materials for organic Diosmin powder manufacturers are often plant sources, such as citrus fruits. These plant - based materials form the basis for the production of organic Diosmin powder.

What techniques do manufacturers use to ensure the quality of organic Diosmin powder?

Manufacturers use advanced extraction and purification techniques. They use state - of - the - art equipment for extraction from raw materials and then purification to meet strict quality standards. Also, comprehensive quality control tests are carried out at every stage of production, including checking chemical purity, potency, and absence of contaminants.

Why is sustainable production important for organic Diosmin powder manufacturers?

Sustainable production is important for organic Diosmin powder manufacturers because it helps to reduce waste, conserve energy, and minimize the environmental impact of their production processes. Moreover, it meets the increasing demand from consumers for sustainable products.

What are the differences between different manufacturers of organic Diosmin powder?

In the global market, different manufacturers of organic Diosmin powder have their own unique features. Some are known for their large - scale production capabilities, which can meet high - volume demands. Others are renowned for their high - quality, niche - market products that target specific customer needs.

How does quality control in the manufacturing process of organic Diosmin powder work?

Quality control in the manufacturing process of organic Diosmin powder works by conducting comprehensive tests at every stage of production. Manufacturers check for chemical purity, potency, and the absence of contaminants. Only by strictly adhering to these quality control measures can they produce safe and effective organic Diosmin powder for various applications.

Related literature

- Organic Diosmin: Production and Quality Assurance"

- "The Role of Manufacturers in the Organic Diosmin Powder Market"

- "Sustainable Manufacturing of Organic Diosmin Powder: Current Trends"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

Bulk purchase of selenium yeast.

2024-11-30

-

The Best Sources of Natural Hops Extract.

2024-11-30

-

Chinese Ganoderma lucidum extract factories.

2024-11-30

-

有机金银花花粉澳大利亚

2024-11-30

-

Chinese stevia extract powder manufacturers.

2024-11-30

-

Chinese Yohimbe Bark Extract Suppliers.

2024-11-30

-

Soy Extract

2024-11-30

-

Selenium yeast

2024-11-30

-

Green Tea Extract

2024-11-30

-

Medicinal Marshmallow Extract

2024-11-30

-

Apricot Powder

2024-11-30

-

melatonin extract

2024-11-30

-

Mulberry Extract

2024-11-30

-

Cocoa Extract

2024-11-30

-

Gynostemma pentaphyllum extract

2024-11-30

-

Red Wine Extract

2024-11-30