- 0086-571-85302990

- sales@greenskybio.com

Manufacturers of Organic Eucommia Ulmoides Extract Powder.

2024-11-26

1. Introduction to Organic Eucommia Ulmoides Extract Powder

Organic Eucommia Ulmoides Extract powder has been gradually emerging in the global market due to its numerous health - promoting properties. Eucommia ulmoides, a traditional Chinese medicinal plant, contains a variety of bioactive compounds. These compounds are believed to have positive effects on human health, such as improving cardiovascular function, enhancing immunity, and having anti - inflammatory properties.

2. The Role of Manufacturers

Manufacturers of organic Eucommia Ulmoides Extract powder play a vital role in the entire production chain. They are the key players in bringing this natural product from raw materials to the final market - ready form.

3. Advanced Extraction Technologies

3.1. Solvent Extraction

One of the commonly used extraction methods by manufacturers is solvent extraction. In this process, solvents are carefully selected to dissolve the active compounds present in Eucommia ulmoides. The solvents need to be non - toxic and easily removable to ensure the purity of the final extract powder. Manufacturers have to consider factors such as the solubility of different compounds in the solvent and the extraction efficiency. For example, ethanol is a popular solvent choice as it can effectively extract a wide range of bioactive components while being relatively safe and easy to handle. However, the extraction process requires precise control of parameters such as temperature, time, and solvent - to - raw - material ratio to optimize the extraction yield and quality.

3.2. Supercritical Fluid Extraction

Supercritical fluid extraction is another advanced technique employed by manufacturers. This method has several advantages over traditional solvent extraction. Supercritical fluids, typically carbon dioxide in a supercritical state, have properties between those of a gas and a liquid. They can penetrate the plant material more effectively and selectively extract the desired compounds. This results in a higher - quality extract with fewer impurities. Moreover, since carbon dioxide is a non - flammable, non - toxic, and easily removable gas, it is an environmentally friendly option. However, the equipment for supercritical fluid extraction is more expensive, and the operation requires specialized knowledge and skills.

4. Quality Control Systems

4.1. Purity Testing

Manufacturers place a high emphasis on quality control. Purity testing is a fundamental aspect. They use various analytical techniques to determine the purity of the Eucommia ulmoides extract powder. For instance, high - performance liquid chromatography (HPLC) is often used to separate and quantify the different components in the extract. This helps to ensure that the product contains the expected levels of active compounds and is free from contaminants such as heavy metals, pesticides, and other harmful substances. Any impurities present in the extract can affect its safety and efficacy, so strict purity standards are adhered to.

4.2. Potency Testing

Potency testing is equally important. The bioactive compounds in Eucommia ulmoides extract powder are responsible for its health - promoting effects. Manufacturers need to ensure that the potency of these compounds is maintained at an appropriate level. This may involve in - vitro and in - vivo assays to evaluate the biological activity of the extract. For example, antioxidant assays can be used to measure the antioxidant capacity of the extract, which is related to its potential health benefits. By conducting regular potency tests, manufacturers can guarantee that their products will have the expected therapeutic or health - promoting effects on consumers.

4.3. Contaminant Screening

Screening for contaminants is an essential part of the quality control process. As mentioned earlier, the presence of heavy metals, pesticides, and other pollutants can pose serious risks to human health. Manufacturers use sophisticated detection methods to identify and quantify these contaminants. For example, atomic absorption spectroscopy can be used to detect trace amounts of heavy metals in the extract powder. If any contaminants are detected above the allowable limits, appropriate measures are taken to remediate the situation, such as rejecting the batch of raw materials or improving the purification process.

5. High - Quality Raw Materials

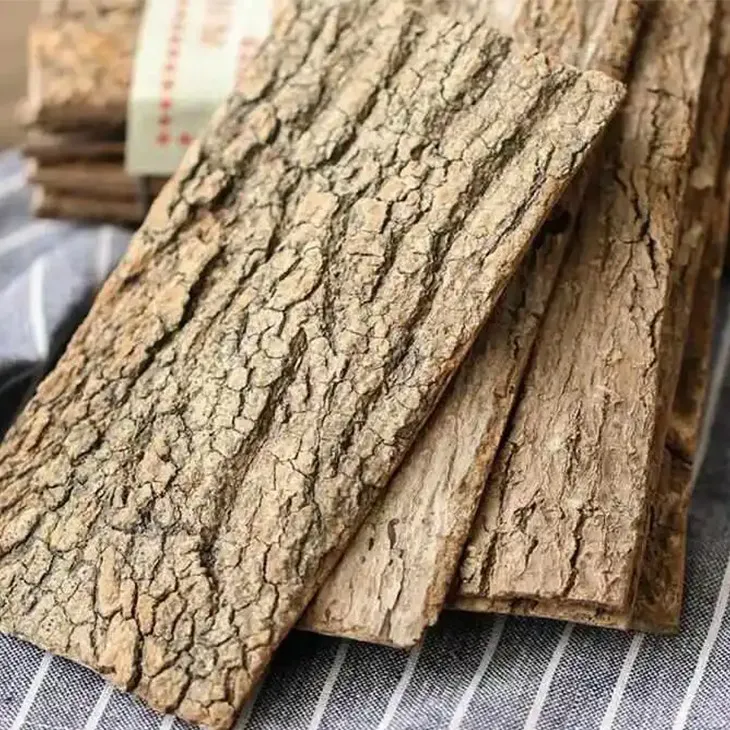

Manufacturers start with high - quality organic Eucommia ulmoides raw materials. These raw materials are typically sourced from carefully cultivated plantations. The quality of the raw materials directly impacts the final product quality.

5.1. Cultivation and Sourcing

The cultivation of Eucommia ulmoides requires specific environmental conditions. Manufacturers often work with farmers or suppliers who follow good agricultural practices. This includes proper soil management, irrigation, and pest control. For example, organic farming methods are preferred to ensure that the plants are free from chemical pesticides and fertilizers. The sourcing of raw materials also involves strict quality inspection at the source. Only plants that meet certain quality criteria, such as a certain age, growth stage, and health status, are selected for extraction.

5.2. Pre - processing of Raw Materials

Before the extraction process, the raw materials undergo pre - processing. This may include steps such as cleaning, drying, and grinding. Cleaning is necessary to remove dirt, debris, and other impurities from the plant material. Drying helps to preserve the raw materials and prevent spoilage. Grinding the dried materials into a suitable particle size is important for efficient extraction. Each of these pre - processing steps needs to be carefully controlled to ensure the quality of the raw materials for the subsequent extraction process.

6. Sustainable Development

Many manufacturers of organic Eucommia ulmoides extract powder are committed to sustainable development.

6.1. Environmentally Friendly Cultivation

They promote environmentally friendly cultivation methods of Eucommia ulmoides. This includes measures such as reducing chemical inputs, conserving water, and protecting biodiversity. For example, some manufacturers encourage the use of natural pest control methods, such as introducing beneficial insects, instead of relying on chemical pesticides. They also support sustainable water management practices in the plantations to ensure that water resources are used efficiently and not depleted. By promoting these environmentally friendly cultivation methods, manufacturers not only contribute to environmental protection but also help to ensure the long - term availability of high - quality raw materials.

6.2. Reducing Environmental Impact during Production

During the production process, manufacturers strive to reduce the environmental impact. In addition to using environmentally friendly extraction methods like supercritical fluid extraction with carbon dioxide, they also focus on waste management. For example, they may recycle or properly dispose of the waste generated during the extraction process, such as spent solvents or plant residues. By reducing waste and minimizing pollution, manufacturers can make their production processes more sustainable and environmentally friendly.

7. Applications in Different Industries

Organic Eucommia ulmoides extract powder has diverse applications in different industries, and manufacturers need to meet the specific requirements of each industry.

7.1. Dietary Supplements

In the dietary supplement industry, the demand for Eucommia ulmoides extract powder is growing. Consumers are increasingly interested in natural products that can enhance their health. Manufacturers need to ensure that their products are formulated in a way that is safe and effective for human consumption. This includes complying with regulatory requirements for dietary supplements, such as proper labeling and dosage instructions. The extract powder may be combined with other nutrients or ingredients to create a comprehensive dietary supplement product.

7.2. Pharmaceuticals

In the pharmaceutical industry, Eucommia ulmoides extract powder has the potential for further development. Research is ongoing to explore its therapeutic applications. Manufacturers need to adhere to strict pharmaceutical quality standards. This involves more comprehensive quality control, including pre - clinical and clinical trials to prove the safety and efficacy of the product. The extract powder may be used as an ingredient in drugs for treating various diseases, such as cardiovascular diseases or osteoporosis.

7.3. Cosmetic Industry

The cosmetic industry also utilizes Eucommia ulmoides extract powder. Its antioxidant and anti - inflammatory properties make it a valuable ingredient in skincare products. Manufacturers need to ensure that the extract powder is suitable for use in cosmetics, which may require additional purification steps to meet the high - quality requirements of the cosmetic industry. The extract powder can be incorporated into creams, lotions, and serums to provide benefits such as anti - aging, moisturizing, and skin - soothing effects.

8. Future Prospects

As the global market for natural products continues to expand, the future prospects for manufacturers of organic Eucommia ulmoides extract powder are promising.

8.1. Market Growth

The increasing consumer awareness of health and the preference for natural products are expected to drive the market growth of Eucommia ulmoides extract powder. Manufacturers are likely to see an increase in demand, both domestically and internationally. They need to be prepared to scale up their production while maintaining high - quality standards.

8.2. Research and Development

Ongoing research into the properties and applications of Eucommia ulmoides will open up new opportunities for manufacturers. New extraction techniques may be developed, or new bioactive compounds may be discovered. Manufacturers can collaborate with research institutions to stay at the forefront of technological advancements and product innovation. This will enable them to introduce new and improved products to the market, further enhancing their competitiveness.

8.3. Global Expansion

With the globalization of the market, manufacturers have the opportunity to expand their business globally. However, they need to be aware of the different regulatory requirements in various countries and regions. By complying with international standards and regulations, manufacturers can penetrate new markets and increase their market share.

FAQ:

What are the main extraction techniques used by manufacturers of Organic Eucommia Ulmoides Extract Powder?

Manufacturers typically use techniques such as solvent extraction or supercritical fluid extraction. These methods help isolate the active compounds from the high - quality organic Eucommia ulmoides raw materials, which are carefully sourced from cultivated plantations. Through these extraction steps, the purity and potency of the final extract powder can be ensured.

How do manufacturers ensure the quality of Organic Eucommia Ulmoides Extract Powder?

Quality control is of utmost importance to these manufacturers. They conduct rigorous tests on the extract powder. These tests include checking for purity, potency, and the absence of contaminants. By performing these comprehensive tests, they can ensure that the product meets the high standards demanded by the international market, whether it is for use in dietary supplements, pharmaceuticals, or the cosmetic industry.

What role does the source of raw materials play for manufacturers of Organic Eucommia Ulmoides Extract Powder?

The raw materials, which are high - quality organic Eucommia ulmoides, are often sourced from carefully cultivated plantations. The quality of the raw materials is fundamental as it is the starting point for the production process. High - quality raw materials contribute to the production of extract powder with good purity and potency, and also help meet the strict quality requirements of the international market.

Are manufacturers of Organic Eucommia Ulmoides Extract Powder concerned about sustainable development?

Yes, many of these manufacturers are committed to sustainable development. They promote environmentally friendly cultivation methods of Eucommia ulmoides. During the production process, they strive to reduce the environmental impact. This is beneficial for the environment and also helps ensure the long - term availability of high - quality raw materials.

What are the applications of Organic Eucommia Ulmoides Extract Powder in different industries?

Organic Eucommia Ulmoides Extract Powder has applications in dietary supplements, pharmaceuticals, and the cosmetic industry. Its various health - promoting properties make it suitable for use in these different sectors. The high - quality extract powder, which is produced with strict quality control and advanced extraction techniques, can meet the specific requirements of each industry.

Related literature

- Title: Advances in the Extraction and Application of Eucommia Ulmoides Extract"

- Title: "Quality Control and Standardization of Organic Eucommia Ulmoides Extract Powder"

- Title: "Sustainable Cultivation of Eucommia Ulmoides for Extract Production"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

Chinese Withania somnifera Extract Factory.

2024-11-26

-

中国松树皮提取物粉粉末供应商

2024-11-26

-

High - quality Marigold Extract Products.

2024-11-26

-

100% Pure Natural Mango - Flavored Powder.

2024-11-26

-

Genistein

2024-11-26

-

Moringa powder

2024-11-26

-

Eucommia Ulmoides Extract

2024-11-26

-

Polygonum multiflorum extract

2024-11-26

-

Hops Extract

2024-11-26

-

Sugarcane Extract

2024-11-26

-

Dandelion Leaf Extract

2024-11-26

-

Hesperidin

2024-11-26

-

Troxerutin

2024-11-26

-

Honeysuckle Pollen

2024-11-26