- 0086-571-85302990

- sales@greenskybio.com

Organic Diosmin Powder Factory.

2024-12-01

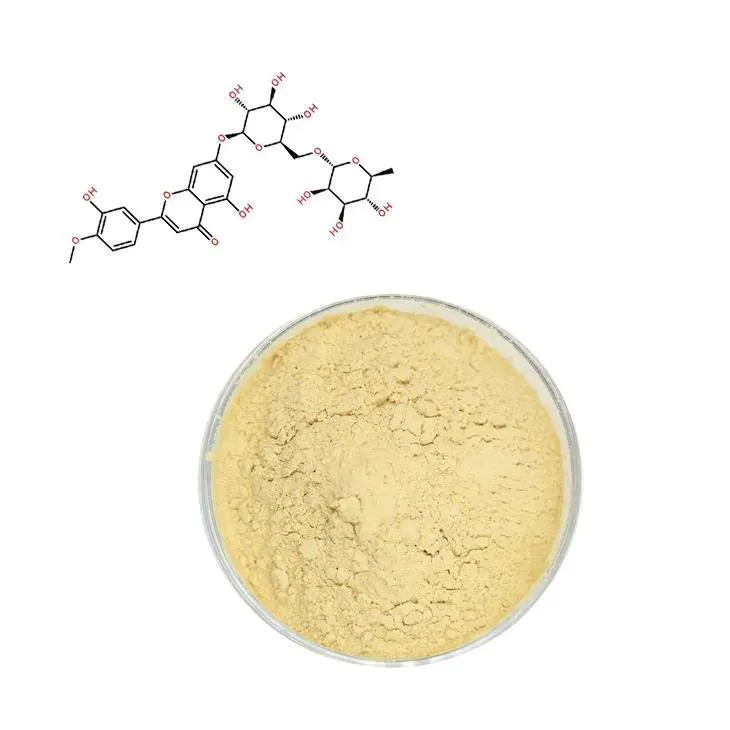

Introduction to Organic Diosmin Powder

Diosmin, as an important bioflavonoid, has a wide range of applications in the medical field. It is highly valued for its various beneficial properties. Organic Diosmin powder, in particular, is in demand due to its purity and natural origin. Organic diosmin powder factories are thus at the forefront of supplying this crucial pharmaceutical ingredient.

Production Process in Organic Diosmin Powder Factories

Raw Material Sourcing

At the very beginning of the production process, strict standards are applied in raw material sourcing. Only the finest and purest natural sources are selected. This is crucial as the quality of the raw material directly impacts the final product. For example, plants that are rich in diosmin and free from contaminants are carefully chosen. These sources are often sourced from specific regions known for their high - quality botanical products.Extraction and Purification

Advanced extraction and purification techniques are employed in organic diosmin powder factories. Chromatographic separation methods may be used to remove impurities effectively. This process is highly sophisticated and requires precision. Firstly, the raw materials are prepared and subjected to an extraction process. Solvents are carefully selected to ensure maximum extraction of diosmin while minimizing the extraction of unwanted substances. After extraction, the purification process begins. This may involve multiple steps of filtration, crystallization, and separation techniques. Through these steps, the purity of the diosmin powder is gradually increased until it meets the high - quality standards of the pharmaceutical industry.Quality Control in Organic Diosmin Powder Factories

These factories adhere to strict quality control standards throughout the production process. Quality control is not just a one - time check but a continuous process. At each stage of production, samples are taken and analyzed. The physical and chemical properties of the diosmin powder are closely monitored. Parameters such as purity, particle size, and solubility are measured. Any deviation from the set standards is immediately addressed. In addition, the factories are often compliant with international quality standards such as Good Manufacturing Practice (GMP). This ensures that the final product is of consistent quality and is suitable for use in pharmaceutical applications.

Technological Innovation in Organic Diosmin Powder Factories

Improving Production Efficiency

From a technological innovation perspective, organic diosmin powder factories are constantly exploring new ways to improve production efficiency. Research and development teams are investing in new extraction solvents and reaction conditions to optimize the production process. New solvents may offer better selectivity and higher extraction yields. For example, some newly developed solvents can dissolve diosmin more effectively while leaving behind impurities. Reaction conditions such as temperature, pressure, and reaction time are also being optimized. By carefully controlling these factors, the production process can be made more efficient.Enhancing Product Quality

In addition to improving efficiency, technological innovation is also focused on enhancing product quality. New purification techniques are being explored to further increase the purity of diosmin powder. For instance, membrane separation technology is being studied for its potential application in diosmin purification. This technology can separate molecules based on their size and charge, providing a more precise purification method. Moreover, advanced analytical techniques are used to better understand the properties of diosmin powder. This enables the factories to make more informed decisions regarding product improvement.Environmental Protection in Organic Diosmin Powder Factories

Environment - Friendly Production Processes

These factories are also making their contributions to environmental protection. They strive to use environment - friendly production processes, reducing waste emissions and energy consumption. Green chemical principles are increasingly being adopted. For example, some factories are implementing processes that minimize the use of harmful chemicals. Instead, they are exploring the use of more sustainable and less toxic solvents. In the extraction process, for instance, plant - based solvents or supercritical fluids are being considered as alternatives to traditional organic solvents.Waste Management and Energy Conservation

Effective waste management is another aspect of environmental protection in these factories. Any waste generated during the production process is properly treated and disposed of. Recycling of waste materials is also explored whenever possible. In terms of energy conservation, energy - efficient equipment is being used. For example, modern extraction and purification systems are designed to consume less energy while maintaining high productivity. Lighting systems are also being upgraded to more energy - saving models, reducing the overall energy consumption of the factory.The Impact of Organic Diosmin Powder Factories on the Global Market

Meeting Global Demand

With the increasing demand for diosmin - based drugs worldwide, organic diosmin powder factories are key suppliers. They play a vital role in meeting the global demand for this important pharmaceutical ingredient. As the awareness of the health benefits of diosmin - based drugs grows, the demand from different regions, including developed and developing countries, is on the rise. These factories are able to scale up their production to meet the increasing market needs.International Trade Promotion

Organic diosmin powder factories not only meet the domestic market needs but also export their products to various countries, promoting international trade in the pharmaceutical ingredient sector. Their products are shipped to different parts of the world, contributing to the global pharmaceutical supply chain. By exporting high - quality diosmin powder, these factories help to improve the availability of diosmin - based drugs globally. This also has a positive impact on the economic development of the regions where these factories are located, as export revenues are generated.Conclusion

In conclusion, the organic diosmin powder factory is a crucial component in the pharmaceutical ingredient industry. Through strict production processes, quality control, technological innovation, and environmental protection efforts, these factories are able to produce high - quality diosmin powder. Their impact on the global market is significant, as they meet the growing demand for diosmin - based drugs and promote international trade. As the pharmaceutical industry continues to evolve, organic diosmin powder factories will likely continue to play an important role in supplying this essential ingredient.

FAQ:

What are the main processes in an organic diosmin powder factory?

An organic diosmin powder factory typically involves processes such as strict raw material sourcing, advanced extraction methods like using chromatographic separation to remove impurities effectively, and purification techniques to ensure high - purity final product.

How does an organic diosmin powder factory ensure product quality?

These factories ensure product quality by adhering to strict quality control standards. They start with carefully selecting the finest and purest natural raw materials. Then, during production, they use advanced extraction and purification techniques. For example, chromatographic separation helps in removing impurities to obtain a high - purity diosmin powder.

What role does technological innovation play in an organic diosmin powder factory?

Technological innovation in an organic diosmin powder factory is crucial. Research and development teams invest in new extraction solvents and reaction conditions. This optimizes the production process, increasing the yield of diosmin and reducing production costs, which makes the product more accessible for pharmaceutical companies.

How does an organic diosmin powder factory contribute to environmental protection?

Organic diosmin powder factories contribute to environmental protection by striving to use environmentally friendly production processes. They reduce waste emissions and energy consumption. Some factories implement green chemical principles in the synthesis process, minimizing the use of harmful chemicals.

What is the impact of the organic diosmin powder factory on the global market?

The organic diosmin powder factory has a significant impact on the global market. With the increasing worldwide demand for diosmin - based drugs, these factories are key suppliers. They supply both domestic and international markets, promoting international trade in the pharmaceutical ingredient sector.

Related literature

- Title: Advances in Diosmin Production in Organic Factories"

- Title: "The Role of Organic Diosmin Powder Factories in the Global Pharmaceutical Supply Chain"

- Title: "Quality Assurance in Organic Diosmin Powder Production"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

The best lemon juice powder in nature.

2024-12-01

-

Organic Vitamin K2 Powder Suppliers

2024-12-01

-

Bulk purchase of L - tyrosine.

2024-12-01

-

Vitamin K2 Manufacturers

2024-12-01

-

100% Pure Natural Rutin.

2024-12-01

-

Chinese Citrus Bioflavonoid Suppliers.

2024-12-01

-

Tinospora cordifolia extract

2024-12-01

-

Medicinal Marshmallow Extract

2024-12-01

-

Fenugreek Extract Powder

2024-12-01

-

Hawthorn powder

2024-12-01

-

Artichoke Extract

2024-12-01

-

Peppermint Extract Powder

2024-12-01

-

Artichoke Leaf Extract

2024-12-01

-

Cat Claw Extract

2024-12-01

-

Tongkat Ali Extract Powder

2024-12-01

-

Lycopene

2024-12-01