- 0086-571-85302990

- sales@greenskybio.com

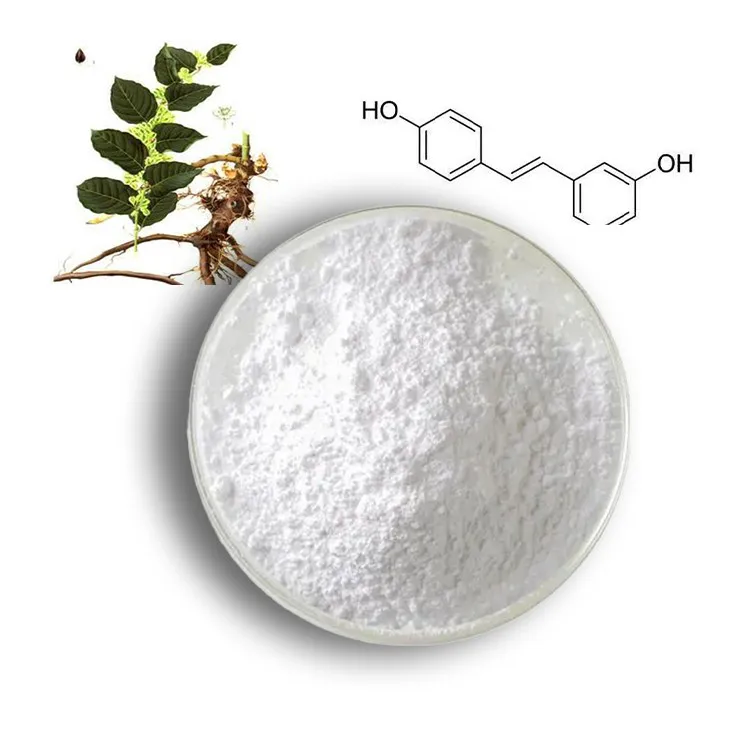

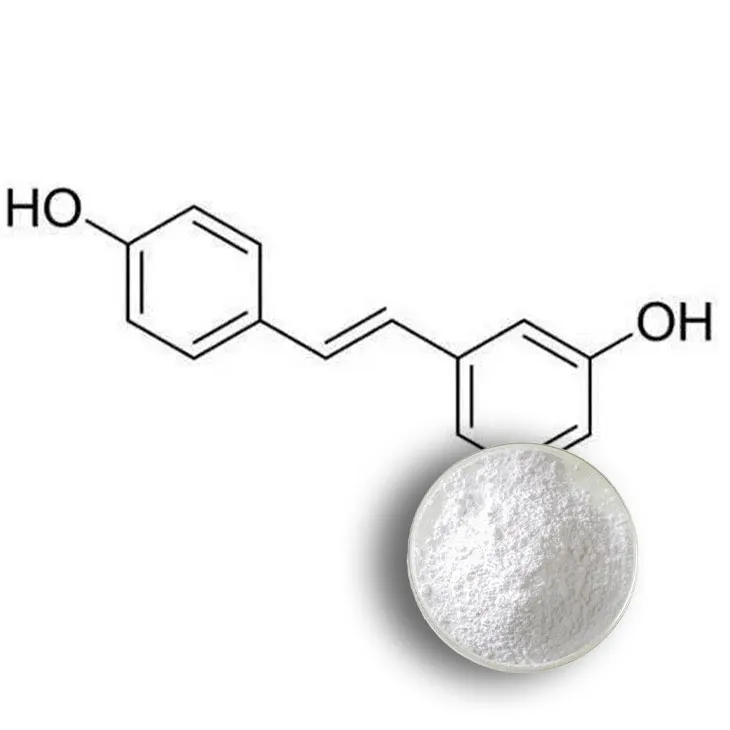

Resveratrol extract manufacturers from China.

2024-12-02

1. Introduction to China's Role in Resveratrol extract Manufacturing

China has become a dominant force in the global Resveratrol extract manufacturing arena. Resveratrol, a natural compound present in plants like grapes and berries, has been the focus of much attention due to its myriad potential health benefits. These benefits range from antioxidant properties to possible anti - aging effects and potential contributions to heart health.

2. Advanced Extraction Techniques

Chinese manufacturers are at the forefront when it comes to employing cutting - edge extraction techniques.

2.1 Solvent Extraction

One of the commonly used methods is solvent extraction. Manufacturers use solvents such as ethanol to extract resveratrol from the plant materials. This method is effective in separating resveratrol from other components in the plant. However, it requires careful control of parameters such as solvent concentration, temperature, and extraction time to ensure high - quality extraction. For example, if the temperature is too high during extraction, it may lead to the degradation of resveratrol, thus reducing the final product's quality.

2.2 Supercritical Fluid Extraction

Another advanced technique is supercritical fluid extraction. In this process, supercritical carbon dioxide is often used as the extraction medium. The advantage of this method is that it can produce a highly pure Resveratrol extract. Supercritical carbon dioxide has properties between a gas and a liquid, which allows it to penetrate the plant material effectively and selectively extract resveratrol. Moreover, it is a cleaner extraction method compared to some traditional solvent - based methods, as there is no solvent residue left in the final product.

3. Rich Supply of Raw Materials

China's vast territory and diverse climate provide a bountiful supply of raw materials for resveratrol extraction.

3.1 Grape - Based Raw Materials

Grape skins and seeds are excellent sources of resveratrol. China is one of the largest grape - producing countries in the world. In regions like Xinjiang and Shandong, grapes are cultivated on a large scale. The local grape industry not only provides a stable source of raw materials for resveratrol extraction but also promotes the development of related industries. For instance, winemaking by - products such as grape pomace can be used as a cost - effective raw material for resveratrol extraction, reducing waste and increasing the overall economic value of the grape industry.

3.2 Berry - Based Raw Materials

Berries such as blueberries and raspberries also contain resveratrol. In recent years, China has seen an increase in berry cultivation. In some mountainous areas, blueberries are grown in large plantations. These berries can be directly used for resveratrol extraction or as a supplement to grape - based raw materials to enhance the diversity of the resveratrol extract's composition. The availability of these berry - based raw materials gives Chinese manufacturers an edge in producing resveratrol extracts with different characteristics.

4. State - of - the - Art Manufacturing Facilities

Chinese resveratrol extract manufacturers are equipped with top - notch facilities.

4.1 Modern Extraction Equipment

They use advanced extraction equipment that can precisely control the extraction process. For example, some modern extraction machines are equipped with automated temperature and pressure control systems. This allows for more consistent and efficient extraction of resveratrol. The equipment also has a large - scale production capacity, which enables manufacturers to meet the growing market demand both domestically and internationally.

4.2 Purification and Concentration Equipment

After extraction, purification and concentration equipment are used to further improve the quality of the resveratrol extract. Chromatography columns are often employed for purification, which can separate resveratrol from impurities with high precision. Concentration equipment, such as rotary evaporators, can increase the concentration of resveratrol in the extract, making it more suitable for various applications in the nutraceutical, cosmetics, and pharmaceutical industries.

5. Sustainable Sourcing of Raw Materials

Most Chinese manufacturers are committed to sustainable sourcing of raw materials.

5.1 Local Plantation Sourcing

By sourcing raw materials from local plantations, manufacturers can reduce the carbon footprint associated with transportation. For example, a resveratrol extract manufacturer in Yunnan province may source grapes from nearby vineyards. This not only ensures the freshness of the raw materials but also supports the local economy. Additionally, local sourcing promotes the development of sustainable agricultural practices. Manufacturers may work with local farmers to implement organic farming methods, which can increase the quality of the raw materials and also have a positive impact on the environment.

5.2 Waste Reduction and Recycling

Manufacturers are also focused on reducing waste during the production process. For instance, in the case of solvent extraction, they may recycle the solvents used to reduce environmental pollution. In addition, by - products from the extraction process, such as plant fiber residues, can be used for other purposes like composting or as raw materials for other industries, thus maximizing the utilization of resources.

6. Stringent Quality Control

Quality control is of paramount importance in the production of resveratrol extracts by Chinese manufacturers.

6.1 Raw Material Inspection

Before the extraction process begins, strict inspection of raw materials is carried out. This includes checking for the presence of contaminants, the freshness of the plant materials, and the content of resveratrol in the raw materials. Only raw materials that meet the specified quality standards are used for extraction. For example, grapes used for extraction must be free from pesticides and other harmful substances, and the resveratrol content should be within a certain range.

6.2 In - process Quality Monitoring

During the extraction, purification, and concentration processes, continuous quality monitoring is implemented. Parameters such as extraction efficiency, purity of the intermediate products, and the stability of the process are closely monitored. If any deviation from the set standards is detected, immediate corrective actions are taken. For instance, if the purity of the resveratrol extract during the purification process is lower than expected, the purification process may be adjusted, such as increasing the number of chromatography columns used or changing the elution conditions.

6.3 Final Product Testing

Once the resveratrol extract is produced, comprehensive final product testing is conducted. This includes testing for the final purity of resveratrol, its bioavailability, and its compliance with international quality standards. Only products that pass all these tests are allowed to be packaged and sold. For example, in the nutraceutical industry, the resveratrol extract must meet the requirements for dietary supplement products in terms of purity, safety, and efficacy.

7. Research and Development Efforts

Chinese manufacturers are actively investing in research and development (R & D).

7.1 Improving Extraction Methods

Researchers are constantly exploring new ways to improve the extraction methods. For example, they are looking into the use of novel solvents or combinations of solvents to increase the extraction efficiency and purity of resveratrol. They are also studying the effects of different extraction parameters on the quality of the final product. By optimizing these parameters, manufacturers can produce resveratrol extracts with higher quality and better performance.

7.2 Enhancing Bioavailability

Another area of focus in R & D is enhancing the bioavailability of resveratrol. Since resveratrol has relatively low bioavailability in its natural form, researchers are investigating methods such as encapsulation and formulation to improve its absorption in the human body. Encapsulation can protect resveratrol from degradation in the digestive tract and increase its solubility, thereby enhancing its bioavailability. These R & D efforts enable Chinese manufacturers to offer more effective resveratrol products in the market.

7.3 New Product Development

Based on the research findings, manufacturers are also involved in new product development. They are creating resveratrol - based products for different applications in the nutraceutical, cosmetics, and pharmaceutical industries. For example, in the cosmetics industry, resveratrol - enriched creams and serums are being developed for their antioxidant and anti - aging properties. In the pharmaceutical industry, research is being conducted on the potential use of resveratrol in treating certain diseases, which may lead to the development of new drugs in the future.

8. Conclusion

Chinese resveratrol extract manufacturers have made significant progress in recent years. With their advanced extraction techniques, rich supply of raw materials, state - of - the - art facilities, sustainable sourcing practices, strict quality control, and continuous R & D efforts, they are well - positioned to compete in the global market. Their products are not only meeting the high - quality requirements of the international market but also driving innovation in the fields of nutraceuticals, cosmetics, and pharmaceuticals. As the demand for resveratrol - based products continues to grow, Chinese manufacturers are expected to play an even more important role in the future.

FAQ:

What are the advantages of Chinese resveratrol extract manufacturers?

Chinese resveratrol extract manufacturers have several advantages. They use advanced extraction techniques and have a rich supply of raw materials from local plantations, which ensures a stable supply and promotes sustainable development. Their state - of - the - art facilities guarantee high - quality extraction, and strict quality control standards are implemented throughout the production process. They also invest in research and development to explore new extraction methods for better purity and bioavailability, enabling them to be competitive in international markets and provide products in demand in nutraceuticals, cosmetics, and pharmaceuticals.

How do Chinese manufacturers ensure the quality of resveratrol extract?

Chinese manufacturers ensure the quality of resveratrol extract by implementing strict standards at every stage of the production process. From the selection of raw materials to the final packaging, comprehensive testing is carried out. They source raw materials from local plantations, which are likely to be of good quality. The use of advanced facilities for extraction also contributes to the high - quality output, and their continuous investment in research and development helps in improving the overall quality of the extract.

What kind of raw materials do Chinese resveratrol extract manufacturers use?

Chinese resveratrol extract manufacturers often use raw materials from plants such as grapes and berries. These plants are rich sources of resveratrol. They usually source these raw materials from local plantations, which not only provides a stable supply but also has the potential to support sustainable development as it reduces the need for long - distance transportation of raw materials.

Why are Chinese resveratrol extract manufacturers investing in research and development?

Chinese resveratrol extract manufacturers are investing in research and development to improve the purity and bioavailability of resveratrol. By exploring new extraction methods, they can enhance the quality of their products. This is important for staying competitive in the international market, as there is a growing demand for high - quality resveratrol in fields like nutraceuticals, cosmetics, and pharmaceuticals. Continuous innovation also allows them to meet the evolving needs and expectations of customers.

How do Chinese resveratrol extract manufacturers contribute to sustainable development?

Chinese resveratrol extract manufacturers contribute to sustainable development by sourcing raw materials from local plantations. This reduces the carbon footprint associated with transporting raw materials over long distances. Also, their focus on high - quality extraction using advanced techniques and strict quality control means less waste and more efficient use of resources. Their investment in research and development for better extraction methods can also lead to more sustainable production processes in the long run.

Related literature

- Resveratrol: Sources, Bioavailability, and Potential Health Benefits"

- "Manufacturing of Resveratrol Extract: Current Practices and Future Perspectives"

- "The Role of Chinese Manufacturers in the Global Resveratrol Market"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

The best lemon juice powder in nature.

2024-12-02

-

Organic Vitamin K2 Powder Suppliers

2024-12-02

-

Bulk purchase of L - tyrosine.

2024-12-02

-

Vitamin K2 Manufacturers

2024-12-02

-

100% Pure Natural Rutin.

2024-12-02

-

Chinese Citrus Bioflavonoid Suppliers.

2024-12-02

-

Feverfew Extract

2024-12-02

-

Hedyotis Diffusa Extract

2024-12-02

-

Echinacea Extract

2024-12-02

-

Camu Camu Extract

2024-12-02

-

Nutmeg Extract

2024-12-02

-

Red Date Extract

2024-12-02

-

Mangosteen extract powder

2024-12-02

-

Astaxanthin

2024-12-02

-

Soy Extract

2024-12-02

-

Green coffee bean Extract

2024-12-02