- 0086-571-85302990

- sales@greenskybio.com

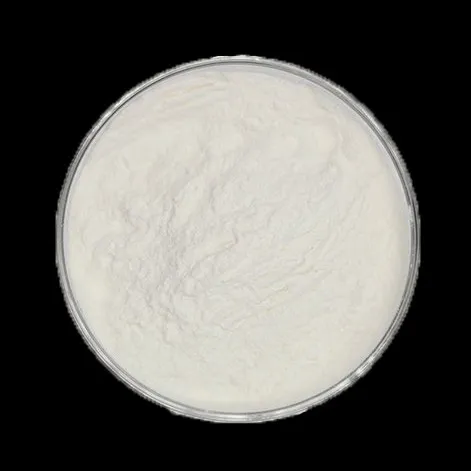

The extraction of saw palmetto extract by using natural wood log method.

2024-11-26

1. Introduction

Saw Palmetto Extract has been recognized for its significant value in a variety of fields, including the pharmaceutical, cosmetic, and dietary supplement industries. The extraction method using natural wood logs is a topic of great interest due to its potential to produce high - quality extracts. This article will explore this extraction method in detail, covering aspects such as the importance of log selection, the extraction process, and the implications for environmental sustainability and product quality control.

2. The Importance of Log Quality

2.1 Source of Logs

The origin of the natural wood logs used for Saw Palmetto Extraction is a crucial factor. Logs sourced from sustainable forests are highly preferred. Sustainable forestry practices ensure that the logs are obtained in an environmentally friendly manner, without causing deforestation or long - term damage to the ecosystem. For example, forests that are managed under strict certification programs, such as the Forest Stewardship Council (FSC) certification, can provide a reliable source of high - quality logs. These forests are typically managed to maintain biodiversity, protect water resources, and support the local communities.

2.2 Purity and Effectiveness

Logs from sustainable forests also offer the advantage of purity. They are less likely to be contaminated with pollutants or harmful substances that could affect the quality of the Saw Palmetto Extract. A pure starting material is essential for obtaining an effective extract. The natural composition of the saw palmetto within the logs is better preserved when sourced from a clean and well - managed forest environment. This, in turn, can lead to a more potent and reliable extract, with higher levels of the active compounds that are desired for various applications.

3. The Extraction Process

3.1 Log Selection

- The first step in the extraction process is the careful selection of natural wood logs. Logs should be of an appropriate size and maturity. Larger logs may contain more saw palmetto berries, but they also need to be in a suitable condition for extraction.

- Inspection for signs of disease or damage is crucial. Logs with signs of fungal infection or physical damage may have a lower quality of saw palmetto, and could potentially introduce contaminants into the extraction process.

3.2 Preparation of Logs

- Once selected, the logs need to be prepared for extraction. This may involve cleaning the logs to remove any dirt, debris, or external contaminants. A simple washing process can be used to ensure that the surface of the logs is clean.

- The logs may then be cut into smaller pieces. This can increase the surface area available for extraction, facilitating the release of the active compounds from the saw palmetto within the logs.

3.3 Extraction of Active Compounds

- The extraction of active compounds from the prepared log pieces can be achieved through various methods. One common method is solvent extraction. Solvents such as ethanol or hexane can be used to dissolve the active compounds present in the saw palmetto within the logs.

- The choice of solvent depends on several factors, including the solubility of the active compounds, the selectivity of the solvent, and the safety and environmental considerations. Ethanol, for example, is a relatively safe and environmentally friendly solvent that can effectively extract many of the active components of saw palmetto.

- After the solvent is added to the log pieces, the mixture is typically agitated or stirred to enhance the extraction process. This helps to ensure that the solvent comes into full contact with the saw palmetto within the logs, allowing for a more complete extraction of the active compounds.

- The extraction process may be carried out at a specific temperature and for a certain period of time. For example, a temperature - controlled extraction at a moderately warm temperature (e.g., around 40 - 60°C) for several hours can often yield good results. The optimal conditions need to be determined based on the characteristics of the logs and the desired quality of the extract.

- Once the extraction is complete, the solvent - containing the extracted active compounds needs to be separated from the remaining log debris. Filtration or centrifugation can be used for this purpose. Filtration through a fine - mesh filter can effectively remove the solid log particles, leaving behind a solution containing the saw palmetto extract.

3.4 Purification and Concentration

- The extracted solution may still contain impurities, so a purification step is often required. This can involve techniques such as chromatography, which can separate the desired active compounds from other substances present in the solution. For example, high - performance liquid chromatography (HPLC) can be used to purify the saw palmetto extract, ensuring a high - quality final product.

- After purification, the extract may need to be concentrated. This can be achieved through methods such as evaporation, where the solvent is removed under controlled conditions to increase the concentration of the active compounds in the extract. Care must be taken during the concentration process to avoid over - heating or degradation of the active compounds.

4. Environmental Sustainability

- The use of natural wood logs for saw palmetto extraction has important implications for environmental sustainability. By sourcing logs from sustainable forests, the extraction process can contribute to the long - term viability of the forest ecosystem. Sustainable forestry practices ensure that new trees are planted to replace those that are harvested, maintaining the forest's carbon sequestration capacity, providing habitat for wildlife, and protecting soil and water resources.

- The choice of extraction solvents also plays a role in environmental sustainability. As mentioned earlier, ethanol is a relatively environmentally friendly solvent. It is biodegradable and has a lower environmental impact compared to some other solvents. Additionally, proper management of solvent waste is essential. Solvent recovery systems can be implemented to recycle and reuse the solvents, reducing the amount of waste generated during the extraction process.

5. Product Quality Control

- Quality control is a critical aspect of the saw palmetto extract production process when using the natural wood log method. Throughout the extraction process, from log selection to the final purified and concentrated extract, various quality control measures need to be implemented.

- For log selection, strict standards should be in place to ensure that only high - quality logs are used. This includes visual inspection for signs of damage or disease, as well as verification of the log's origin from sustainable sources.

- During the extraction process, the quality of the solvents, the extraction conditions (such as temperature and time), and the efficiency of the separation and purification steps need to be monitored. Analytical techniques such as HPLC can be used to analyze the composition of the extract at different stages, ensuring that the desired active compounds are present in the correct amounts and that impurities are within acceptable limits.

- Finally, the finished saw palmetto extract product should be subjected to comprehensive quality testing. This includes testing for potency, purity, and stability. The product should meet all relevant regulatory requirements and quality standards to ensure its safety and effectiveness for use in various applications.

6. Conclusion

The extraction of saw palmetto extract using the natural wood log method is a complex but rewarding process. The quality of the log source is fundamental, as it directly impacts the purity and effectiveness of the extract. The extraction process involves multiple steps, from log selection to the extraction, purification, and concentration of the active compounds. This method also has significant implications for environmental sustainability and product quality control. By following best practices in all aspects of the process, it is possible to produce high - quality saw palmetto extract that can meet the demands of various industries while also being environmentally responsible.

FAQ:

What are the main advantages of using natural wood logs for saw palmetto extract extraction?

The main advantage is that logs from sustainable forests can provide a pure and effective starting point for the extraction. This helps ensure the quality of the saw palmetto extract.

What are the key steps in the extraction process of saw palmetto extract using natural wood logs?

The key steps include log selection and then the extraction of the active compounds. Each step requires careful handling to preserve the beneficial properties of saw palmetto.

How does the extraction method using natural wood logs affect environmental sustainability?

Using logs from sustainable forests in the extraction method can contribute to environmental sustainability. It ensures that the source of the raw material is managed in an environmentally friendly way, reducing the negative impact on the forest ecosystem.

What role does product quality control play in the extraction of saw palmetto extract using natural wood logs?

Product quality control is very important. It ensures that the extraction process is carried out properly, and the final saw palmetto extract meets the required quality standards. This includes making sure that the beneficial properties of saw palmetto are preserved during the extraction process.

How can the quality of the source material (natural wood logs) be ensured?

The quality of the source material can be ensured by sourcing logs from sustainable forests. This helps to ensure that the logs are pure and of high quality, which is crucial for obtaining an effective saw palmetto extract.

Related literature

- The Benefits of Saw Palmetto Extract: A Comprehensive Review"

- "Sustainable Extraction of Natural Compounds: The Case of Saw Palmetto"

- "Saw Palmetto Extract: Quality Control in the Extraction Process"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

Chinese Withania somnifera Extract Factory.

2024-11-26

-

中国松树皮提取物粉粉末供应商

2024-11-26

-

High - quality Marigold Extract Products.

2024-11-26

-

100% Pure Natural Mango - Flavored Powder.

2024-11-26

-

Tamarind extract powder

2024-11-26

-

Milk Thistle Extract

2024-11-26

-

Apricot Powder

2024-11-26

-

Green Tea Extract

2024-11-26

-

Nutmeg Extract

2024-11-26

-

Artichoke Extract

2024-11-26

-

Shikonin

2024-11-26

-

Hesperidin

2024-11-26

-

Hawthorn Extract

2024-11-26

-

Angelica sinensis extract

2024-11-26