- 0086-571-85302990

- sales@greenskybio.com

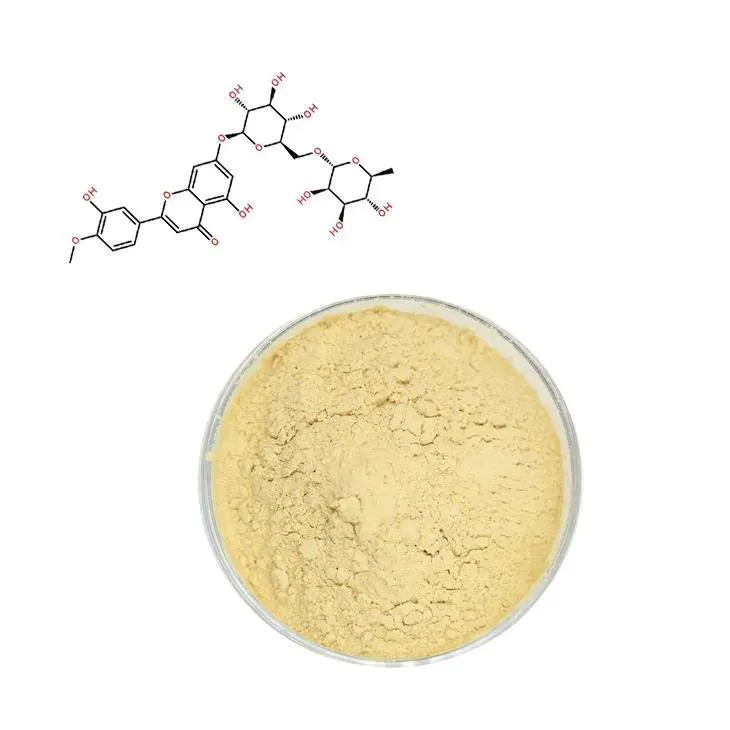

The process of extracting diosmin particles from diosmin.

2024-12-01

1. Introduction

Diosmin is a flavonoid with various beneficial properties, such as antioxidant, anti - inflammatory, and vascular protection effects. Extracting Diosmin microparticles from Diosmin can enhance its bioavailability and performance in different applications. This article aims to comprehensively discuss the process of this extraction, covering aspects from raw material preparation to quality control and property optimization.

2. Raw Material Preparation for Extraction

2.1 Source Selection

- The source of diosmin is crucial. It can be obtained from natural plants such as citrus fruits. When selecting the source, factors like the diosmin content in the plant, the availability of the plant, and the cost of procurement need to be considered.

- For example, oranges are a common source. The peel of oranges contains a relatively high amount of diosmin. However, the quality of oranges may vary depending on the variety, cultivation conditions, and harvesting time.

- Once the source is selected, pretreatment of the raw material is necessary. For plant - based sources, this may involve cleaning to remove dirt, pesticides, and other contaminants.

- Drying is another important step. Different drying methods can be used, such as air drying or low - temperature drying. Air drying is a simple and cost - effective method, but it may take a longer time. Low - temperature drying can better preserve the active components of diosmin but requires more energy and equipment.

- After drying, the raw material may need to be ground into a powder. The fineness of the powder can affect the extraction efficiency. A finer powder generally provides a larger surface area for extraction, which is beneficial for the subsequent extraction process.

3. Use of Advanced Equipment and Solvents

3.1 Equipment

- Modern extraction processes often rely on advanced equipment. One of the commonly used devices is the supercritical fluid extraction (SFE) apparatus. SFE uses supercritical fluids, such as supercritical carbon dioxide, as the extraction solvent. The advantage of using supercritical fluids is that they have properties between gases and liquids, which can penetrate into the matrix of the raw material more easily and selectively extract the target compound.

- Another important equipment is the ultrasonic - assisted extraction device. Ultrasonic waves can create cavitation effects in the solvent, which helps to break the cell walls of the raw material and release the diosmin more effectively. This method can significantly reduce the extraction time and improve the extraction yield.

- Solvent selection is also a critical factor in the extraction process. In addition to supercritical carbon dioxide, traditional organic solvents such as ethanol can also be used. Ethanol is a polar solvent that can dissolve diosmin well.

- However, when using organic solvents, safety and environmental concerns need to be taken into account. For example, proper ventilation and waste treatment are required to prevent solvent vapor inhalation and environmental pollution.

- Mixtures of solvents can also be used to optimize the extraction. For instance, a combination of ethanol and water can adjust the polarity of the solvent system, which may be more suitable for extracting diosmin from different sources or with different impurity levels.

4. Extraction Process Steps

4.1 Loading the Raw Material

- The pretreated raw material powder is loaded into the extraction vessel. The amount of raw material loaded should be appropriate to ensure efficient extraction. If the amount is too large, the extraction may be incomplete due to insufficient solvent contact; if it is too small, it will reduce the production efficiency.

- After loading the raw material, the selected solvent is added to the extraction vessel. The ratio of solvent to raw material needs to be carefully controlled. For example, in the case of using ethanol as a solvent, a common ratio may be 5:1 to 10:1 (solvent: raw material by volume).

- When using the SFE apparatus, the temperature and pressure are adjusted to the supercritical state of the solvent. For carbon dioxide, the typical supercritical conditions are around 31.1 °C and 7.38 MPa. Once the supercritical state is reached, the extraction process begins.

- In the case of ultrasonic - assisted extraction, the ultrasonic power and frequency are set according to the characteristics of the raw material and solvent. For example, an ultrasonic power of 200 - 500 W and a frequency of 20 - 50 kHz are often used.

- The extraction time also affects the extraction yield. For SFE, the extraction time may range from 30 minutes to several hours, depending on the nature of the raw material and the desired extraction efficiency.

- For ultrasonic - assisted extraction, a shorter extraction time can often be achieved compared to traditional extraction methods. Usually, 10 - 30 minutes may be sufficient, but it still needs to be optimized based on specific experimental conditions.

5. Quality Control Measures during the Extraction

5.1 Purity Analysis

- During the extraction process, it is necessary to monitor the purity of the extracted diosmin microparticles. High - performance liquid chromatography (HPLC) is a commonly used method for purity analysis. HPLC can separate and quantify the diosmin in the extract accurately, allowing for the detection of impurities such as other flavonoids or plant - derived substances.

- Another method for purity determination is thin - layer chromatography (TLC). TLC is a relatively simple and rapid screening method. It can provide a preliminary indication of the purity of the extract and help to identify the presence of major impurities.

- Since the focus is on extracting diosmin microparticles, particle size analysis is essential. Laser diffraction is a widely used technique for particle size measurement. It can accurately measure the size distribution of the microparticles in the extract.

- Controlling the particle size is important because it can affect the bioavailability and physical properties of the diosmin microparticles. For example, smaller particles may have a higher surface area - to - volume ratio, which can lead to better dissolution and absorption in the body.

- The extraction yield is calculated to evaluate the efficiency of the extraction process. The yield is determined by comparing the amount of diosmin obtained from the extraction with the amount of diosmin present in the original raw material.

- The formula for calculating the yield is: Yield (%)=(amount of extracted diosmin/amount of diosmin in raw material)× 100. By monitoring the yield at different stages of the extraction process, appropriate adjustments can be made to optimize the extraction conditions.

6. Optimization of Properties of Diosmin Microparticles

6.1 Surface Modification

- Surface modification of diosmin microparticles can improve their performance. One approach is to coat the microparticles with biocompatible polymers. For example, coating with polyethylene glycol (PEG) can increase the hydrophilicity of the microparticles, which is beneficial for their dispersion in aqueous solutions and their interaction with biological systems.

- Another surface modification method is to attach functional groups to the microparticle surface. For instance, attaching carboxyl or amino groups can enable the microparticles to interact with specific biomolecules, which may be useful for targeted drug delivery applications.

- Controlling the crystallinity of diosmin microparticles can also affect their properties. Amorphous diosmin microparticles may have a higher solubility compared to their crystalline counterparts. This can be achieved through different crystallization techniques or by adding additives during the extraction or post - extraction processing.

- For example, rapid cooling during the crystallization process can promote the formation of amorphous diosmin microparticles. Additionally, adding certain surfactants can also inhibit crystal growth and lead to the formation of amorphous or less - crystalline microparticles.

7. Conclusion

The extraction of diosmin microparticles from diosmin involves a complex process that includes raw material preparation, the use of advanced equipment and solvents, strict quality control, and property optimization. Each step plays a crucial role in obtaining high - quality diosmin microparticles with enhanced performance. Future research may focus on further improving the extraction efficiency, exploring more environmentally friendly solvents, and developing novel surface modification and property control methods to expand the applications of diosmin microparticles in various fields such as medicine, cosmetics, and food.

FAQ:

What are the key steps in preparing the raw materials for diosmin microparticle extraction?

The key steps may include sourcing high - quality diosmin, purifying it if necessary, and ensuring its proper storage conditions. The raw material should be free from contaminants that could interfere with the extraction process. It might also involve grinding or milling the diosmin to an appropriate particle size to increase the surface area available for extraction.

What advanced equipment is typically used in the extraction of diosmin microparticles?

Some common advanced equipment used could be high - performance liquid chromatographs (HPLC) which can be used for separation and purification during the extraction process. Centrifuges are also often utilized to separate different components based on their density. Additionally, ultrasonic devices may be used for better mixing and extraction efficiency.

How do solvents play a role in the extraction of diosmin microparticles?

Solvents are crucial in the extraction process. They help dissolve the diosmin and separate it from other components. The choice of solvent depends on the solubility properties of diosmin. A suitable solvent should be able to effectively extract diosmin while minimizing the extraction of unwanted substances. For example, some organic solvents might be preferred due to their ability to dissolve diosmin well.

What are the main quality control measures during the extraction of diosmin microparticles?

Main quality control measures include monitoring the purity of the extracted diosmin microparticles. This can be done through spectroscopic techniques such as UV - Vis spectroscopy to check for the presence of impurities. Another measure is to control the particle size distribution, which can be measured using techniques like laser diffraction. Also, ensuring the consistency of the extraction process by following standardized operating procedures is important.

How can the properties of diosmin microparticles be optimized for better performance?

The properties of diosmin microparticles can be optimized in several ways. For example, by carefully controlling the extraction conditions such as temperature, pressure, and extraction time, the particle size and morphology can be influenced. Additionally, post - extraction treatments like surface modification may be carried out to enhance properties such as solubility or bioavailability.

Related literature

- “Efficient Extraction of Diosmin and its Microparticle Characterization”

- “Advanced Techniques in Diosmin Microparticle Extraction: A Review”

- “Optimizing Diosmin Microparticle Extraction for Pharmaceutical Applications”

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

Chinese selenium yeast manufacturers.

2024-12-01

-

The best lavender extract on the market.

2024-12-01

-

Bulk purchase of cocoa extract.

2024-12-01

-

Organic Sea - buckthorn Oil Powder Factory.

2024-12-01

-

Organic D - mannose, Australia.

2024-12-01

-

The Most Highly - Rated L - Cysteine.

2024-12-01

-

Active ingredients in lily extract.

2024-12-01

-

Bulk purchase of bladder horn extract.

2024-12-01

-

Active components in black pepper extract.

2024-12-01

-

Carrageenan Extract Powder

2024-12-01

-

Lemon Balm Extract

2024-12-01

-

Eucommia Ulmoides Extract

2024-12-01

-

Saffron Extract Powder

2024-12-01

-

Cassia Seed Extract

2024-12-01

-

Cactus Extract

2024-12-01

-

Calendula Extract

2024-12-01

-

Epimedium extract powder

2024-12-01

-

Licorice Root Extract Powder

2024-12-01

-

Chia Seed Powder

2024-12-01