- 0086-571-85302990

- sales@greenskybio.com

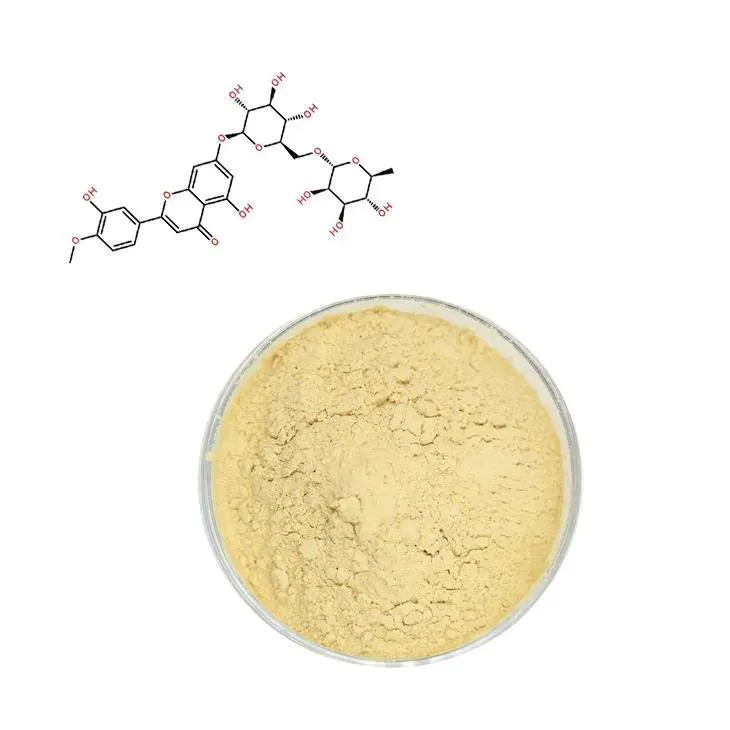

The process of extracting pure diosmin from diosmin.

2024-12-01

1. Introduction

Diosmin is a flavonoid with various beneficial properties, such as its potential role in improving venous function and reducing inflammation. The extraction of pure Diosmin from Diosmin - containing sources is of great significance in the pharmaceutical and nutraceutical industries. This process is complex and requires a comprehensive understanding of multiple aspects, including raw material sourcing, purification techniques, and quality control.

2. Sourcing of Raw Materials

2.1 Natural Sources Diosmin can be obtained from natural sources such as citrus fruits. Citrus peels are a rich source of diosmin. These raw materials are often by - products of the citrus juice industry, which makes them a cost - effective option. However, the quality and diosmin content can vary depending on factors such as the type of citrus, the region of growth, and the harvesting time.

2.2 Cultivation Considerations When considering the cultivation of plants for diosmin extraction, factors like soil quality, climate, and irrigation play a crucial role. For example, citrus trees require well - drained soil and a warm, sunny climate. Proper cultivation practices can ensure a higher diosmin yield in the raw materials.

3. Initial Pretreatment of Raw Materials

3.1 Cleaning and Sorting Once the raw materials are sourced, they need to be thoroughly cleaned to remove dirt, debris, and any contaminants. Sorting is also necessary to separate damaged or low - quality parts of the raw materials. This step is essential to ensure the quality of the final diosmin product.

3.2 Drying Drying the raw materials is often a crucial step. It helps in reducing the moisture content, which can prevent spoilage during storage and subsequent processing. Different drying methods such as air drying, oven drying, or freeze - drying can be used depending on the nature of the raw materials and the requirements of the extraction process.

4. Extraction Methods

4.1 Solvent Extraction

- Solvent extraction is one of the most common methods for extracting diosmin. Organic solvents such as ethanol, methanol, or ethyl acetate are often used.

- The choice of solvent depends on factors like the solubility of diosmin in the solvent, the selectivity of the solvent towards diosmin, and the safety and environmental impact of the solvent.

- During solvent extraction, the raw materials are typically soaked in the solvent for a certain period of time. The temperature and agitation rate can also be adjusted to optimize the extraction efficiency.

4.2 Supercritical Fluid Extraction

- Supercritical fluid extraction (SFE) is a more advanced extraction technique. Carbon dioxide (CO2) is often used as the supercritical fluid.

- The advantage of SFE is that it can provide a more selective extraction, and the supercritical CO2 is non - toxic and environmentally friendly. It can also be easily removed from the extract, leaving behind a relatively pure diosmin product.

- However, SFE requires specialized equipment and higher operating costs compared to solvent extraction.

5. Purification by Chromatography

5.1 Principles of Chromatography Chromatography is a powerful separation technique based on the differential distribution of components between a stationary phase and a mobile phase. In the case of diosmin purification, different types of chromatography can be used, such as high - performance liquid chromatography (HPLC) or column chromatography.

5.2 HPLC in Diosmin Purification

- HPLC is a widely used technique for purifying diosmin. It offers high resolution and can separate diosmin from other impurities effectively.

- The mobile phase in HPLC is carefully selected to optimize the separation. For diosmin, a combination of solvents such as water and acetonitrile is often used.

- The stationary phase, usually a packed column with a specific material, interacts differently with diosmin and other components, allowing for their separation.

5.3 Column Chromatography

- Column chromatography is another option for diosmin purification. It involves packing a column with a stationary phase material, such as silica gel or alumina.

- The sample containing diosmin is loaded onto the top of the column, and a solvent (mobile phase) is passed through the column. Different components in the sample will move at different rates through the column, allowing for the separation of diosmin from impurities.

- Column chromatography is relatively simple and cost - effective compared to HPLC, but it may have lower resolution in some cases.

6. Importance of Parameter Control

6.1 Temperature Control

- Temperature plays a crucial role in the extraction and purification processes. In solvent extraction, an appropriate temperature can increase the solubility of diosmin in the solvent, thus improving the extraction efficiency.

- During chromatography, temperature can affect the interaction between the stationary phase, mobile phase, and the components being separated. For example, in HPLC, a stable temperature is often required to ensure reproducible results.

6.2 Pressure Control

- In supercritical fluid extraction, pressure is a key parameter. By adjusting the pressure, the density and solvent properties of the supercritical fluid (e.g., CO2) can be changed, which affects the extraction selectivity and efficiency.

- Even in chromatography, especially in HPLC where the mobile phase is often pumped at a certain pressure, proper pressure control is necessary to ensure a stable flow rate and accurate separation.

6.3 Solvent Composition Control

- The composition of the solvent is critical in both extraction and chromatography. In solvent extraction, the right combination of solvents can enhance the extraction of diosmin while minimizing the extraction of unwanted impurities.

- In chromatography, the solvent composition of the mobile phase determines the separation efficiency. Different solvents or solvent mixtures can be used to optimize the separation of diosmin from other components.

7. Quality Control in the Extraction Process

7.1 Purity Analysis

- At each stage of the extraction process, purity analysis of the diosmin product is essential. Techniques such as high - performance liquid chromatography (HPLC) can be used to determine the purity of diosmin.

- The purity of the final diosmin product should meet the required standards, which are often set by regulatory authorities in the pharmaceutical or nutraceutical industries.

7.2 Identification of Impurities

- It is also important to identify and quantify the impurities in the diosmin product. Mass spectrometry can be used in combination with HPLC to identify the chemical structure of impurities.

- Knowing the types and amounts of impurities can help in optimizing the extraction and purification processes to further improve the quality of the diosmin product.

7.3 Quality Assurance in Raw Materials

- Quality assurance starts from the raw materials. The diosmin content in the raw materials should be determined accurately. Spectroscopic methods such as ultraviolet - visible spectroscopy can be used to estimate the diosmin content in the raw materials.

- Any contaminants or pesticides in the raw materials need to be detected and controlled within acceptable limits to ensure the safety and quality of the final diosmin product.

8. Conclusion

The extraction of pure diosmin from diosmin is a multi - step process that requires careful consideration of various factors. From sourcing high - quality raw materials to implementing advanced purification techniques and strict quality control measures, each step is crucial in obtaining a high - purity diosmin product. With the increasing demand for diosmin in various industries, continuous research and improvement in the extraction process are necessary to meet the market requirements and ensure the safety and efficacy of the final product.

FAQ:

What are the main sources of raw materials containing diosmin?

The main sources of raw materials containing diosmin are citrus fruits. These fruits are rich in flavonoids, including diosmin. For example, oranges, lemons, and grapefruits are common sources. Their peels and pulp may contain a certain amount of diosmin, which can be used as the starting material for extraction.

How does chromatography work in the purification of diosmin?

Chromatography works based on the differential partitioning of diosmin between a stationary phase and a mobile phase. In column chromatography, for instance, the stationary phase is packed in a column. The sample containing diosmin is introduced into the column with the mobile phase. Different components in the sample, including diosmin, will interact differently with the stationary and mobile phases. Due to these different interactions, diosmin will move through the column at a different rate compared to other substances, allowing for its separation and purification.

Why is strict control of temperature, pressure, and solvent composition important in the extraction process?

Strict control of temperature, pressure, and solvent composition is crucial in the extraction process. Temperature can affect the solubility of diosmin in the solvent and the rate of chemical reactions. If the temperature is too high or too low, it may lead to incomplete extraction or degradation of diosmin. Pressure can influence the physical state of the solvent and the efficiency of separation processes. Regarding solvent composition, different solvents or solvent mixtures have different affinities for diosmin and other impurities. The right solvent composition ensures that diosmin is selectively dissolved and separated from other components.

What are the typical quality control measures during the extraction of pure diosmin?

Typical quality control measures during the extraction of pure diosmin include spectroscopic analysis, such as UV - Vis spectroscopy to determine the concentration and purity of diosmin based on its characteristic absorption spectra. High - performance liquid chromatography (HPLC) is also commonly used to separate and quantify diosmin and detect any impurities. Additionally, physical property measurements like melting point determination can provide information about the purity of the extracted diosmin. Regular sampling and analysis at each stage of the extraction process are carried out to ensure the final product meets the required quality standards.

Can the extraction process be scaled up for industrial production?

Yes, the extraction process can be scaled up for industrial production. However, it requires careful consideration of several factors. For example, larger - scale equipment needs to be used for handling larger volumes of raw materials and solvents. The control systems for temperature, pressure, and solvent flow need to be adjusted to ensure consistent operation across a larger scale. Additionally, waste management becomes more important on an industrial scale. Despite these challenges, with proper engineering and process optimization, the extraction of pure diosmin can be successfully scaled up to meet industrial demands.

Related literature

- “Advances in Diosmin Extraction Techniques”

- “Purification of Diosmin: A Review of Modern Methods”

- “The Role of Chromatography in Diosmin Isolation”

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

The best lemon juice powder in nature.

2024-12-01

-

Organic Vitamin K2 Powder Suppliers

2024-12-01

-

Bulk purchase of L - tyrosine.

2024-12-01

-

Vitamin K2 Manufacturers

2024-12-01

-

100% Pure Natural Rutin.

2024-12-01

-

Chinese Citrus Bioflavonoid Suppliers.

2024-12-01

-

Phyllanthus Emblica Extract

2024-12-01

-

Avocado Extract Powder

2024-12-01

-

Acerola Extract

2024-12-01

-

Nutmeg Extract

2024-12-01

-

Red Wine Extract

2024-12-01

-

Artichoke Extract

2024-12-01

-

Buckthorn bark extract

2024-12-01

-

Aguaje Extract

2024-12-01

-

Cassia Seed Extract

2024-12-01

-

Chasteberry Extract

2024-12-01