- 0086-571-85302990

- sales@greenskybio.com

A Complete Guide to Astaxanthin Grinding Process: Key Points by Step

2024-12-19

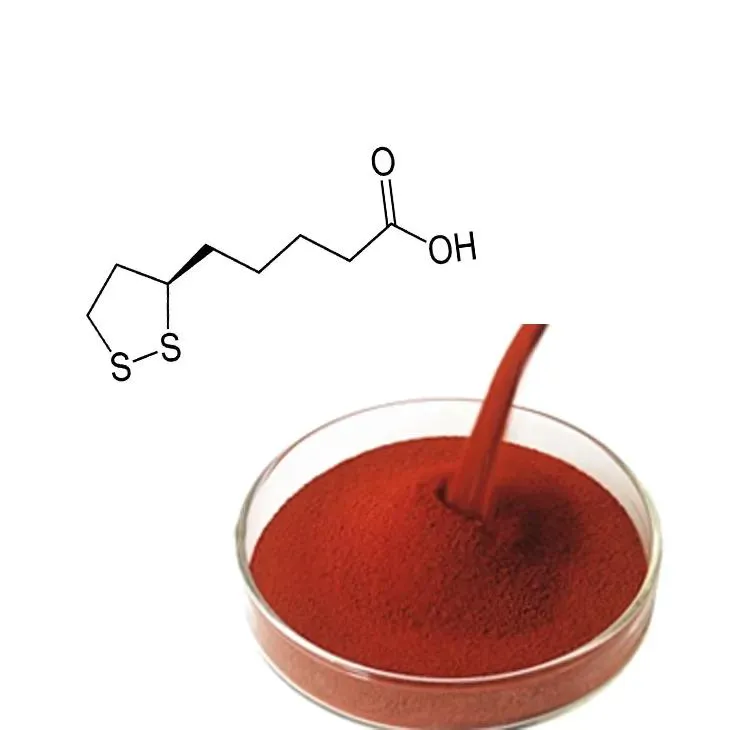

1. Introduction to Astaxanthin

Astaxanthin is a powerful antioxidant that has gained significant attention in various industries, including the food, pharmaceutical, and cosmetic sectors. It is a carotenoid pigment that imparts a characteristic red color and offers numerous health benefits. Understanding the grinding process of Astaxanthin is crucial for professionals involved in its production and processing.

2. Why Grinding Astaxanthin is Necessary

2.1 Particle Size Reduction Grinding astaxanthin helps in reducing the particle size. This is important as it can enhance the solubility and bioavailability of astaxanthin. Smaller particles can be more easily absorbed by the body, which is especially significant in applications where astaxanthin is used as a dietary supplement.

2.2 Uniformity in Mixtures In products where astaxanthin is combined with other ingredients, such as in cosmetics or food formulations, grinding ensures a more uniform mixture. This helps in achieving consistent quality and performance of the final product.

3. Pre - Grinding Considerations

3.1 Source of Astaxanthin Astaxanthin can be obtained from different sources, such as microalgae (Haematococcus pluvialis), yeast, or synthetic production. The source can influence the physical and chemical properties of astaxanthin, which in turn affects the grinding process. For example, astaxanthin from microalgae may have different moisture content and purity levels compared to the synthetic form.

3.2 Purity and Quality High - purity astaxanthin is often preferred for grinding. Impurities can interfere with the grinding process and may also affect the final quality of the ground product. It is essential to ensure that the astaxanthin meets the required quality standards before starting the grinding process.

3.3 Equipment Selection

- Ball Mills: These are commonly used for grinding astaxanthin. They consist of a rotating cylinder containing balls. The movement of the balls grinds the astaxanthin. Ball mills are suitable for achieving fine particle sizes, but they may require longer grinding times.

- Jet Mills: Jet mills use high - velocity jets of gas to grind the astaxanthin. They are known for producing very fine particles with a narrow particle size distribution. However, they can be more expensive and require careful handling.

- Hammer Mills: Hammer mills are relatively simple and cost - effective. They use hammers to break down the astaxanthin. However, they may not be as effective in achieving extremely fine particle sizes as ball mills or jet mills.

4. The Grinding Process Step - by - Step

4.1 Preparation of Astaxanthin Before grinding, the astaxanthin should be properly prepared. This may involve drying if the astaxanthin has a high moisture content. Moisture can affect the grinding efficiency and the quality of the ground product. Additionally, any large agglomerates should be broken down manually or using a pre - grinder.

4.2 Loading the Grinding Equipment

- For ball mills, the astaxanthin is placed inside the rotating cylinder along with the grinding balls. The ratio of astaxanthin to the grinding balls should be optimized for efficient grinding.

- In jet mills, the astaxanthin is fed into the grinding chamber through a suitable feeder system. The gas pressure and flow rate for the jets need to be set correctly.

- Hammer mills require the astaxanthin to be fed into the chamber where the hammers are located. Care should be taken to ensure an even feed to avoid overloading in certain areas.

4.3 Grinding Operation

- In ball mills, the cylinder is rotated at a specific speed. The grinding time depends on the desired particle size. Longer grinding times generally result in finer particles, but it also increases the risk of over - grinding, which can affect the quality of astaxanthin.

- Jet mills operate by the impact of high - velocity gas jets on the astaxanthin. The gas velocity and grinding pressure are critical parameters that need to be controlled. These parameters can be adjusted based on the starting particle size of the astaxanthin and the desired final particle size.

- Hammer mills function by the impact of the hammers on the astaxanthin. The speed of the hammers and the feed rate of the astaxanthin are important factors. If the hammers rotate too fast or the feed rate is too high, it can lead to incomplete grinding or overheating of the product.

4.4 Monitoring the Grinding Process

- Particle Size Analysis: Regularly check the particle size of the ground astaxanthin using techniques such as laser diffraction or microscopy. This helps in determining whether the grinding is progressing as expected and when to stop the grinding process.

- Temperature Monitoring: Grinding can generate heat, especially in equipment like hammer mills. Excessive heat can degrade astaxanthin. Therefore, it is important to monitor the temperature during the grinding process and take appropriate measures, such as cooling, if the temperature rises above a certain limit.

5. Factors Influencing Grinding Quality

5.1 Grinding Time As mentioned earlier, the grinding time has a direct impact on the particle size of astaxanthin. Insufficient grinding time may result in large particles, while over - grinding can lead to changes in the chemical structure of astaxanthin, reducing its effectiveness.

5.2 Grinding Equipment Parameters

- In ball mills, the size and material of the grinding balls can affect the grinding quality. Larger balls may be more suitable for initial grinding, while smaller balls are better for achieving finer particle sizes.

- For jet mills, the gas pressure, flow rate, and nozzle design play important roles. Optimal gas pressure and flow rate are required to ensure efficient grinding, and the nozzle design can influence the distribution of the grinding force.

- In hammer mills, the shape, size, and speed of the hammers are crucial factors. Well - designed hammers can provide more effective impact on the astaxanthin, leading to better grinding results.

5.3 Feed Rate The rate at which astaxanthin is fed into the grinding equipment affects the grinding quality. A too - high feed rate can overload the equipment, resulting in incomplete grinding. On the other hand, a too - low feed rate can lead to inefficient use of the equipment and longer grinding times.

6. Safety Precautions during Astaxanthin Grinding

6.1 Dust Control Astaxanthin powder can be easily dispersed in the air during grinding, forming dust. Inhalation of astaxanthin dust may be harmful to the respiratory system. Therefore, proper dust control measures should be implemented. This can include using dust collection systems, wearing masks, and ensuring good ventilation in the grinding area.

6.2 Fire and Explosion Hazards Some grinding equipment, such as jet mills, may use gases under pressure. There is a risk of fire or explosion if the gases are not handled properly. It is necessary to follow safety regulations regarding the handling of gases, including proper storage, leak detection, and prevention of static electricity.

6.3 Equipment Maintenance Regular maintenance of grinding equipment is essential for safety. Malfunctioning equipment can pose various risks, such as unexpected movements or release of parts. Maintenance should include inspection of moving parts, replacement of worn - out components, and ensuring proper lubrication.

7. Post - Grinding Handling

7.1 Collection and Packaging After grinding, the astaxanthin powder needs to be carefully collected. This can be done using appropriate collection devices such as cyclones or filters. Once collected, the astaxanthin powder should be packaged in suitable containers. The containers should be airtight and light - resistant to protect the astaxanthin from degradation.

7.2 Quality Control

- Re - analysis of Particle Size: After collection, it is advisable to re - analyze the particle size to ensure that it has not changed during the collection and packaging processes.

- Chemical Purity Testing: Conduct chemical purity tests to verify that the astaxanthin has not been contaminated during grinding or post - grinding handling. This can include tests for impurities such as heavy metals or residual solvents.

7.3 Storage Astaxanthin should be stored in a cool, dry, and dark place. The storage temperature should be maintained within a specific range to prevent degradation. Additionally, the storage area should be free from pests and contaminants.

8. Conclusion

The grinding process of astaxanthin is a complex but crucial step in its production and processing. By understanding the pre - grinding considerations, following the step - by - step grinding process, taking into account the factors influencing grinding quality, implementing safety precautions, and handling the post - grinding operations properly, professionals can ensure the production of high - quality astaxanthin products. This comprehensive guide provides the necessary knowledge and guidelines for those involved in astaxanthin grinding operations.

FAQ:

Q1: What are the main factors influencing the grinding quality of astaxanthin?

The main factors include the type of grinding equipment used. Different equipment may have different grinding mechanisms and efficiencies. The particle size of the raw astaxanthin material also matters. If the initial particles are too large or have irregular shapes, it can affect the grinding result. Additionally, the grinding environment, such as temperature and humidity, can play a role. For example, high humidity might cause clumping and affect the fineness of the ground astaxanthin.

Q2: What safety precautions should be taken during the astaxanthin grinding process?

First, proper personal protective equipment (PPE) should be worn, such as safety goggles to protect the eyes from any flying particles. Gloves are also necessary to prevent skin contact with the astaxanthin, which might be irritating in some cases. The grinding equipment should be regularly maintained and checked for any potential malfunctions that could lead to accidents. Also, the grinding area should be well - ventilated to avoid the accumulation of dust, which can pose a respiratory hazard.

Q3: How should the astaxanthin be prepared before grinding?

Before grinding, the astaxanthin should be inspected for purity and quality. Any impurities should be removed as much as possible. It might need to be dried if it has absorbed moisture, as excessive moisture can interfere with the grinding process. Also, the astaxanthin should be evenly distributed in the grinding chamber or container to ensure uniform grinding.

Q4: What are the common methods for post - grinding handling of astaxanthin?

After grinding, the astaxanthin powder needs to be stored properly. It should be placed in an airtight container to prevent oxidation, as astaxanthin is sensitive to oxygen. The container should be stored in a cool, dry place, away from direct sunlight. Additionally, the ground astaxanthin may need to be further processed, such as sieving to obtain a more uniform particle size distribution.

Q5: How can one ensure the consistency of the grinding process for astaxanthin?

To ensure the consistency of the grinding process, it is crucial to use standardized operating procedures. This includes setting the same grinding parameters such as speed, time, and pressure (if applicable) for each batch. Regular calibration of the grinding equipment is also necessary to maintain its performance. Monitoring the particle size and quality of the ground astaxanthin during the process can help detect any deviations early and make adjustments accordingly.

Related literature

- Astaxanthin: Properties, Sources, and Applications in the Food and Nutraceutical Industries"

- "Optimization of Astaxanthin Extraction and Processing: A Review"

- "The Role of Grinding in Enhancing the Bioavailability of Astaxanthin"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Acai Berry Extract

2024-12-19

-

Tongkat Ali Extract

2024-12-19

-

Longan Extract

2024-12-19

-

Clove Powder

2024-12-19

-

Mango flavored powder

2024-12-19

-

Jujube Extract

2024-12-19

-

Lemon Juice Powder

2024-12-19

-

Artichoke Leaf Extract

2024-12-19

-

Licorice Root Extract Powder

2024-12-19

-

Phyllanthus Emblica Extract

2024-12-19