- 0086-571-85302990

- sales@greenskybio.com

A Complete Guide to Saw Palmetto Extract Grinding Process: Step - by - Step Key Points

2024-12-10

Introduction

Saw Palmetto Extract has gained significant popularity in various industries, especially in the field of herbal medicine and dietary supplements. The grinding process of Saw Palmetto Extract is a crucial step that determines the quality and effectiveness of the final product. In this comprehensive guide, we will explore the step - by - step key points of the Saw Palmetto Extract grinding process.

Raw Material Preparation

1. Selection of Saw Palmetto Berries

- The first step in the grinding process is to carefully select high - quality saw palmetto berries. These berries should be fully ripe and free from any signs of disease or damage.

- Look for berries that have a rich, dark color, which is often an indication of their maturity and nutrient content.

- Once the berries are selected, they need to be thoroughly cleaned. Remove any dirt, debris, or foreign matter that may be present on the surface of the berries.

- This can be achieved by using a gentle stream of water or a specialized cleaning apparatus. However, it is important to avoid over - soaking the berries as this may lead to the loss of some of their valuable components.

- After cleaning, the berries should be dried. Drying helps to reduce the moisture content, which is essential for the grinding process.

- There are different methods of drying, such as air - drying or using a low - temperature drying oven. The key is to ensure that the berries are dried evenly and that the moisture level is reduced to an appropriate level (usually around 10 - 15%).

Grinding Equipment

1. Types of Grinders

- There are several types of grinders that can be used for saw palmetto extract grinding. One common type is the roller mill. Roller mills are known for their ability to produce a fine and uniform grind. They work by crushing the dried berries between two or more rollers.

- Another option is the hammer mill. Hammer mills are more suitable for larger - scale operations as they can handle a greater quantity of berries at a time. They use high - speed rotating hammers to break down the berries into smaller particles.

- The mortar and pestle can also be used for small - scale grinding, especially for laboratory or artisanal production. Although it is a more labor - intensive method, it allows for a more controlled grinding process.

- Capacity: Depending on the scale of production, it is important to choose a grinder with an appropriate capacity. For small - scale producers, a grinder with a lower capacity may be sufficient, while large - scale manufacturers will require a high - capacity grinder.

- Grind Size: Different applications may require different grind sizes. Some products may need a very fine grind, while others may be acceptable with a coarser grind. The grinder should be able to produce the desired grind size consistently.

- Ease of Cleaning: Since saw palmetto extract can be sticky and leave residues, it is crucial to select a grinder that is easy to clean. This helps to maintain the hygiene of the equipment and prevent cross - contamination between batches.

- Cost: The cost of the grinder is also an important factor. While high - end grinders may offer more advanced features and better performance, they may not be affordable for all producers. It is necessary to find a balance between cost and functionality.

The Grinding Process

1. Initial Grinding

- Once the dried and prepared saw palmetto berries are placed in the grinder, the initial grinding process begins. Start the grinder at a slow speed and gradually increase it to avoid overloading the equipment.

- The goal of this initial grinding is to break down the berries into smaller chunks. This stage may produce a relatively coarse grind, but it is an important first step in the overall grinding process.

- After the initial grinding, the partially ground berries are further processed in the intermediate grinding stage. This may involve using a different grinding mechanism or adjusting the settings of the grinder.

- The aim is to further reduce the particle size and make the grind more uniform. This can be achieved by increasing the grinding time or changing the speed and pressure of the grinder.

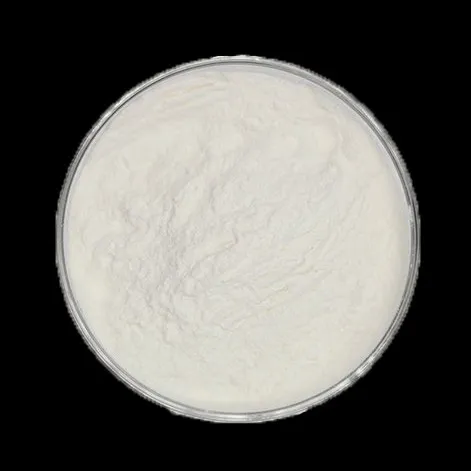

- The final stage of the grinding process is the fine grinding. At this point, the goal is to produce a very fine powder - like grind of the saw palmetto extract.

- Special attention should be paid to the temperature during this stage, as excessive heat can degrade the active components of the extract. Some grinders are equipped with cooling systems to prevent overheating.

Quality Control

1. Particle Size Analysis

- After the grinding process, it is essential to analyze the particle size of the saw palmetto extract. This can be done using specialized equipment such as a particle size analyzer.

- The particle size should be within the specified range for the intended use of the extract. For example, if it is for use in a dietary supplement in capsule form, a certain particle size may be required to ensure proper encapsulation and bioavailability.

- Another important aspect of quality control is homogeneity testing. This ensures that the ground saw palmetto extract is evenly distributed and that there are no large clumps or areas of inconsistent grind.

- Methods such as visual inspection, sieve analysis, or more advanced spectroscopic techniques can be used to assess the homogeneity of the extract.

- It is necessary to check for purity and potential contaminants in the ground saw palmetto extract. This includes testing for the presence of heavy metals, pesticides, and other harmful substances.

- Regular quality control checks help to ensure that the final product is safe and meets the required quality standards.

Storage of Ground Saw Palmetto Extract

1. Packaging

- The ground saw palmetto extract should be packaged in a suitable container. This can be a plastic or glass container, depending on the requirements.

- The packaging should be airtight to prevent moisture absorption and oxidation, which can affect the quality of the extract.

Conclusion

The grinding process of saw palmetto extract is a multi - step and complex operation that requires careful attention to detail. From the selection and preparation of raw materials to the choice of grinding equipment, the actual grinding process, quality control, and storage, each step plays a crucial role in ensuring the production of high - quality saw palmetto extract. By following the step - by - step key points outlined in this guide, producers can optimize their grinding process and produce a product that meets the highest quality standards.

FAQ:

What are the main steps in the saw palmetto extract grinding process?

The main steps typically include raw material preparation, where the saw palmetto berries are selected and cleaned. Then, there is the initial grinding to break down the berries into smaller particles. After that, further grinding may be carried out to achieve the desired fineness. There could also be steps for quality control during and after the grinding process to ensure the consistency and quality of the extract.

Why is grinding important in saw palmetto extract production?

Grinding is important because it helps to break down the saw palmetto berries, which are the source of the extract. By grinding, the active compounds in the berries can be more easily extracted. It also helps in creating a uniform product. A proper grinding process can enhance the efficiency of extraction and ultimately the quality of the final saw palmetto extract.

What equipment is typically used for saw palmetto extract grinding?

Commonly used equipment includes grinders such as hammer mills or ball mills. Hammer mills are often used for the initial coarse grinding as they can quickly break down the berries. Ball mills are more suitable for finer grinding and can be used to achieve a more precise particle size. Additionally, there may be sieves or filters used in combination with the grinders for quality control.

How can one ensure the quality during the saw palmetto extract grinding process?

To ensure quality during the grinding process, one should start with high - quality raw materials. Regularly check and maintain the grinding equipment to ensure it is operating at optimal conditions. Monitor the particle size during the grinding process. Also, conduct quality tests on samples of the ground material at different stages of the process to make sure it meets the required standards for the final extract.

Are there any safety precautions to be taken during the saw palmetto extract grinding process?

Yes, there are several safety precautions. Operators should wear appropriate personal protective equipment such as gloves and safety glasses. The grinding equipment should be properly installed and maintained to prevent any mechanical failures. There should also be proper ventilation in the grinding area to avoid the inhalation of dust particles generated during the grinding process.

Related literature

- Saw Palmetto Extract: Properties and Applications"

- "The Science behind Saw Palmetto Berry Processing"

- "Advances in Saw Palmetto Extract Production Technology"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Pure 85% Tomentil Extract.

2024-12-10

-

Acerola Juice Powder

2024-12-10

-

Yellow Pine Extract

2024-12-10

-

Longan Extract

2024-12-10

-

Nutmeg Extract

2024-12-10

-

Curcuma Longa Extract

2024-12-10

-

Pomegranate Extract

2024-12-10

-

Curcuma Longa Extract/Turmeric extract

2024-12-10

-

Tongkat Ali Extract Powder

2024-12-10

-

Fig Extract

2024-12-10

-

Citrus Aurantii Extract

2024-12-10