- 0086-571-85302990

- sales@greenskybio.com

Reliability and Efficiency: Pillars for Top - tier Diosmin Manufacturers to Provide Effective Products.

2024-12-23

1. Introduction

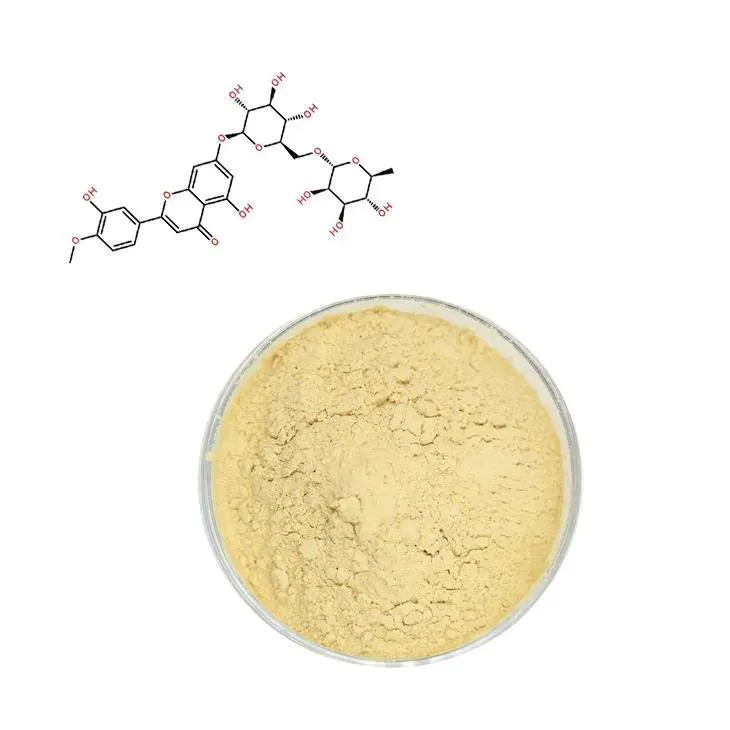

Diosmin is a flavonoid that has been increasingly recognized for its various health benefits. In the market, the top - tier Diosmin manufacturers play a crucial role in ensuring that consumers can access high - quality products. Reliability and efficiency are two key aspects that distinguish these leading manufacturers from others. This article will delve into how these manufacturers uphold these principles to produce effective Diosmin - based products.

2. The Significance of Reliability

Reliability is of utmost importance in the production of Diosmin products. It encompasses multiple aspects within the manufacturing process.

2.1 Quality Assurance Systems

Top - tier Diosmin manufacturers have comprehensive quality assurance systems in place. These systems start from the very beginning - the inspection of raw materials.

- Raw Material Inspection: The quality of raw materials directly affects the final product. Manufacturers need to ensure that the Diosmin - containing plants or other sources are of high quality. They conduct thorough tests to check for purity, potency, and the absence of contaminants. For example, if Diosmin is sourced from citrus fruits, the fruits must be free from pesticides and other harmful substances.

- Manufacturing Process Control: Throughout the manufacturing process, strict control is maintained. This includes factors such as temperature, pressure, and reaction time in chemical processes. Any deviation from the optimal conditions could lead to a product with reduced efficacy or even potential safety risks.

- Final Product Packaging: Packaging is not just about aesthetics; it also plays a role in product reliability. Adequate packaging protects the Diosmin product from environmental factors such as moisture, light, and air. For instance, light - sensitive Diosmin products may be packaged in opaque containers to prevent degradation.

2.2 Regulatory Compliance

Another aspect of reliability is regulatory compliance. Diosmin manufacturers must adhere to strict regulations.

- Food and Drug Regulations: In many countries, Diosmin products, whether sold as dietary supplements or pharmaceuticals, need to meet certain food and drug regulations. Manufacturers must ensure that their products are labeled accurately, including information about dosage, ingredients, and potential side effects.

- Quality Standards: There are also industry - specific quality standards that Diosmin manufacturers should follow. These standards help to ensure consistency and reliability across different batches of products.

3. The Importance of Efficiency

Efficiency is equally crucial for top - tier Diosmin manufacturers. It enables them to produce high - quality products while also remaining competitive in the market.

3.1 Streamlining Operations

Manufacturers strive to streamline their operations in various ways.

- Supply Chain Management: Efficient supply chain management ensures a steady flow of raw materials. By optimizing relationships with suppliers, manufacturers can reduce lead times and avoid shortages. For example, they may establish long - term contracts with reliable suppliers of Diosmin - rich plants.

- Production Scheduling: Careful production scheduling helps to maximize the use of resources. Manufacturers can plan production runs to minimize downtime and make the best use of equipment and labor. This may involve using advanced software to predict demand and schedule production accordingly.

3.2 Waste Reduction

Reducing waste is an important part of efficiency in Diosmin manufacturing.

- Material Waste: Minimizing material waste can be achieved through accurate measurement and control during the manufacturing process. For example, in the extraction of Diosmin from plants, precise extraction techniques can ensure that as much of the active ingredient as possible is obtained, reducing the amount of plant material that goes to waste.

- Energy Waste: Energy - efficient manufacturing processes are also a focus. This may include using energy - saving equipment or optimizing heating and cooling systems in the production facility. By reducing energy waste, manufacturers can lower their production costs and also contribute to environmental sustainability.

3.3 Innovation in Production Techniques

Innovation in production techniques is a key driver of efficiency for Diosmin manufacturers.

- Advanced Extraction Methods: New extraction methods are constantly being developed to improve the yield and purity of Diosmin. For example, supercritical fluid extraction may be used to obtain a higher - quality Diosmin product compared to traditional extraction methods.

- Biotechnological Approaches: Some manufacturers may explore biotechnological approaches to produce Diosmin. This could involve using genetically engineered microorganisms to produce Diosmin more efficiently and with greater control over the product quality.

4. How Reliability and Efficiency Result in Effective Products

The combination of reliability and efficiency has a direct impact on the effectiveness of Diosmin products.

4.1 Consistent Product Quality

Thanks to reliable manufacturing processes, top - tier manufacturers can ensure consistent product quality. This means that each batch of Diosmin product contains the correct amount of the active ingredient and meets the same high - quality standards. Consumers can rely on these products to have the expected health benefits.

4.2 Cost - effectiveness

Efficient operations lead to cost - effectiveness. By reducing waste and streamlining production, manufacturers can lower their production costs. This, in turn, can make Diosmin products more affordable for consumers. Affordable yet high - quality products are more likely to be accessible to those in need, such as patients with venous disorders who may benefit from Diosmin.

4.3 Innovation - driven Efficacy

Innovation in production techniques can enhance the efficacy of Diosmin products. For example, new extraction methods may result in a more bioavailable form of Diosmin, which can be more effectively absorbed by the body. This means that consumers can experience better health outcomes from using these products.

5. Conclusion

In conclusion, reliability and efficiency are indeed the pillars for top - tier Diosmin manufacturers to provide effective products. By focusing on these two aspects, manufacturers can ensure high - quality, cost - effective, and efficacious Diosmin - based products. As the demand for Diosmin products continues to grow, it is essential that manufacturers uphold these principles to meet the needs of consumers and contribute to the overall well - being of society.

FAQ:

1. What are the key aspects of the quality assurance systems in top Diosmin manufacturers?

Top Diosmin manufacturers' quality assurance systems cover multiple aspects. Firstly, they conduct strict raw material inspection to ensure the purity and quality of the starting materials. This includes testing for contaminants and verifying the authenticity of the raw materials. During the production process, they closely monitor each step to maintain consistency. In the final product packaging, they ensure proper sealing and labeling, which also plays a role in product quality control.

2. How do top Diosmin manufacturers streamline their operations?

These manufacturers streamline operations in several ways. They may use advanced production planning software to optimize the production schedule. By carefully coordinating the different stages of production, they can reduce idle time and increase overall productivity. Also, they invest in automated machinery which can perform tasks more precisely and quickly than manual labor, thus speeding up the production process.

3. What kind of production technique innovations can be found in top Diosmin manufacturers?

Top Diosmin manufacturers often innovate in production techniques. For example, they may develop new extraction methods to obtain Diosmin more efficiently and with higher purity. Some might use biotechnology - based approaches to enhance the production process. Additionally, they could be exploring new ways of formulating Diosmin products, such as creating more stable and bioavailable formulations.

4. Why are reliability and efficiency important for Diosmin manufacturers?

Reliability is crucial because it ensures that the Diosmin products are of consistent quality. Customers rely on these products for various health benefits, and unreliable products may not deliver the expected results. Efficiency, on the other hand, allows manufacturers to produce high - quality products at a reasonable cost. It also enables them to meet the market demand in a timely manner, making the products more accessible to those who need them.

5. How do reliability and efficiency contribute to the effectiveness of Diosmin products?

Reliability in the manufacturing process means that each batch of Diosmin products has the same high - quality standards. This consistency is important for the product's effectiveness as it ensures that the active ingredient, Diosmin, is present in the right amount and form. Efficiency helps in reducing production costs, which can potentially lead to more research and development. This, in turn, can improve the product's effectiveness through better formulation or enhanced production techniques.

Related literature

- The Role of Quality Assurance in Diosmin Production"

- "Efficiency Improvements in Diosmin Manufacturing"

- "Reliability and Effectiveness: A Study of Diosmin - based Products"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Pure 85% Tomentil Extract.

2024-12-23

-

Elderberry Extract

2024-12-23

-

Dandelion Root Extract

2024-12-23

-

Medicinal Marshmallow Extract

2024-12-23

-

Beetroot juice Powder

2024-12-23

-

Rosemary extract

2024-12-23

-

Avocado Extract Powder

2024-12-23

-

Aguaje Extract

2024-12-23

-

Europen Bilberry Extract

2024-12-23

-

Centella Asiatica Extract

2024-12-23

-

Acerola Juice Powder

2024-12-23