- 0086-571-85302990

- sales@greenskybio.com

Understand the main processes of diosmin manufacturing in the food industry.

2024-12-20

1. Introduction

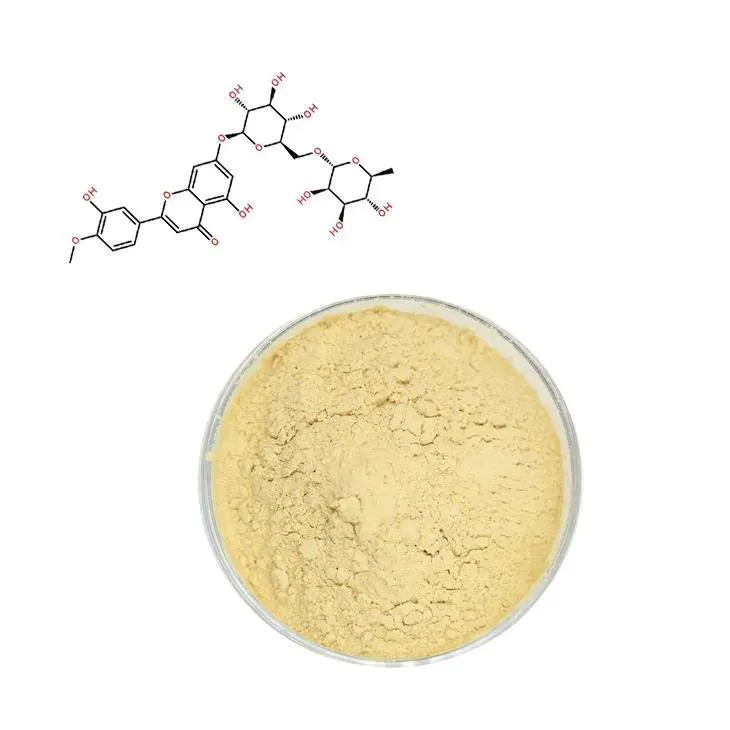

Diosmin is a flavonoid compound that has gained significant importance in the food industry. It is known for its various beneficial properties, such as antioxidant, anti - inflammatory, and vascular - protective effects. The manufacturing process of Diosmin in the food industry is a complex and multi - step procedure that ensures the production of a high - quality product suitable for consumption. This article will provide an in - depth overview of the main processes involved in Diosmin manufacturing.

2. Raw Material Selection

The selection of raw materials is the first and crucial step in diosmin manufacturing. In the food industry, plant sources are predominantly used as they are rich in flavonoids.

- Citrus Fruits: Citrus fruits, such as oranges and lemons, are excellent sources of diosmin. They contain a significant amount of flavonoid - rich compounds in their peels and membranes. The peel of oranges, for example, is a common starting material for diosmin extraction. It is not only abundant but also relatively easy to obtain as a by - product of the citrus juice industry.

- Hesperidin - Rich Plants: Some plants are rich in Hesperidin, which can be further converted into diosmin. These plants are also considered valuable raw materials. For instance, certain species of buckwheat contain Hesperidin - like compounds that can be used in the diosmin production process.

3. Extraction Process

Once the raw materials are selected, the extraction process begins. The goal of extraction is to isolate the flavonoid - rich fraction that contains diosmin from the plant material.

- Solvent Selection: The choice of solvent is critical in the extraction process. Commonly used solvents include ethanol and methanol. These solvents have the ability to dissolve the flavonoid compounds effectively. Ethanol is often preferred in the food industry as it is considered a relatively safe solvent for food - grade applications. It can penetrate the plant cells and dissolve the flavonoid - rich substances.

- Extraction Methods: There are different extraction methods available. One common method is maceration, where the plant material is soaked in the solvent for a certain period. For example, the citrus peel may be cut into small pieces and soaked in ethanol for several days. During this time, the flavonoid compounds gradually dissolve into the solvent. Another method is percolation, in which the solvent is continuously passed through the plant material. This method can be more efficient in extracting the desired compounds as it ensures a continuous supply of fresh solvent to the plant material.

- Optimizing Extraction Conditions: Parameters such as temperature, time, and solvent - to - material ratio need to be optimized. For instance, a higher temperature may increase the extraction rate, but it also needs to be carefully controlled to avoid degradation of the flavonoid compounds. The extraction time also affects the yield of the flavonoid - rich fraction. If the time is too short, not all the diosmin may be extracted, while if it is too long, it may lead to the extraction of unwanted compounds.

4. Purification Steps

After extraction, the obtained extract contains not only diosmin but also other compounds. Therefore, purification steps are necessary to isolate and purify diosmin.

- Chromatographic Techniques: Chromatography is a powerful tool for purifying diosmin. High - Performance Liquid Chromatography (HPLC) is often used in the food industry for this purpose. In HPLC, the extract is passed through a column filled with a stationary phase. Different compounds in the extract interact differently with the stationary phase and the mobile phase (the solvent), resulting in their separation. Diosmin can be selectively collected based on its retention time in the column. Another chromatographic technique is column chromatography, which is a more traditional method but still effective. In column chromatography, a column is packed with a suitable adsorbent material, and the extract is loaded onto the column. As the solvent is passed through the column, the compounds are separated based on their affinity for the adsorbent.

- Recrystallization: Recrystallization is another purification method. The extracted and partially purified diosmin may be dissolved in a suitable solvent at a high temperature. As the solution cools down, diosmin crystals start to form while the impurities remain in the solution. The crystals can be then filtered and dried to obtain a purer form of diosmin. This method is relatively simple and cost - effective, especially for removing some of the less - soluble impurities.

5. Quality Control Checks

Quality control checks are carried out at every stage of the diosmin manufacturing process.

- Raw Material Inspection: Before the extraction process, the raw materials are inspected for their quality. This includes checking for the presence of pesticides, heavy metals, and other contaminants. Only raw materials that meet the strict quality standards are used in the production process. For example, citrus peels are tested for pesticide residues as these can be transferred to the final diosmin product.

- During - Process Monitoring: During the extraction and purification processes, various parameters are monitored. For extraction, the solvent concentration, temperature, and extraction time are continuously measured to ensure that they are within the optimal range. In the purification steps, the purity of the intermediate products is checked regularly. For HPLC purification, the chromatogram is analyzed to ensure that the separation of diosmin from other compounds is complete and accurate.

- Final Product Analysis: The final diosmin product undergoes comprehensive analysis. The purity of diosmin is determined using analytical techniques such as HPLC. The chemical structure of the diosmin is also verified to ensure that it has not been altered during the manufacturing process. In addition, tests are carried out to check for the presence of any residual solvents or impurities. The final product must meet all the relevant food industry standards and regulations regarding purity, safety, and quality.

6. Conclusion

The manufacturing of diosmin in the food industry involves a series of well - defined processes. From the careful selection of raw materials to the final quality control checks, each step is crucial in ensuring the production of a high - quality diosmin product. The use of appropriate extraction and purification techniques, along with strict quality control measures, enables the food industry to produce diosmin that can be safely used in various food applications. As research on diosmin continues, further improvements in the manufacturing process may be expected to enhance the quality and availability of this important flavonoid compound.

FAQ:

What are the typical raw materials for diosmin manufacturing in the food industry?

Typically, plant sources rich in flavonoids are used as raw materials for diosmin manufacturing in the food industry.

Why are solvents like ethanol or methanol used in the extraction process?

Solvents such as ethanol or methanol are used in the extraction process because they can effectively isolate the flavonoid - rich fraction which contains diosmin from the raw materials.

What is the role of chromatographic techniques in diosmin manufacturing?

Chromatographic techniques play a crucial role in diosmin manufacturing as they are used to separate and purify diosmin from other compounds during the purification steps.

How important are quality control checks in diosmin manufacturing for the food industry?

Quality control checks are extremely important in diosmin manufacturing for the food industry. They are carried out at every stage to ensure that the final product meets the required standards for use in the food industry.

Can diosmin be manufactured from non - plant sources?

Traditionally, diosmin is manufactured from plant sources rich in flavonoids. There is no common information indicating that it can be easily manufactured from non - plant sources currently.

Related literature

- Diosmin Production and Its Applications in the Food Industry"

- "Advanced Techniques in Diosmin Manufacturing for Food - grade Quality"

- "Raw Material Selection for Diosmin Manufacture in Food"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Pure 85% Tomentil Extract.

2024-12-20

-

Ginger Extract

2024-12-20

-

Pueraria Lobata Extract

2024-12-20

-

Mulberry Extract

2024-12-20

-

Maitake Mushroom Extract

2024-12-20

-

Beta Carotene

2024-12-20

-

Alfalfa Meal

2024-12-20

-

American Ginseng Root Extract

2024-12-20

-

Konjac Powder

2024-12-20

-

Oyster Mushroom Extract Powder

2024-12-20

-

Withania Somnifera Extract

2024-12-20