- 0086-571-85302990

- sales@greenskybio.com

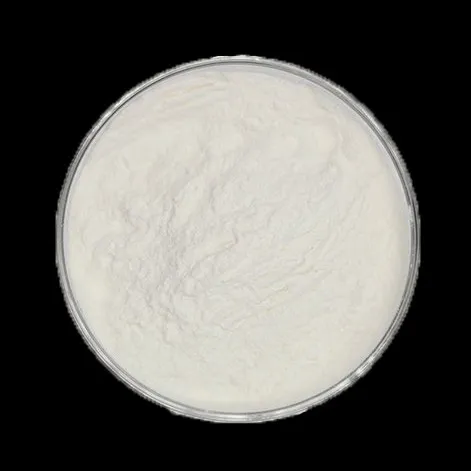

Ensuring Purity: Quality and Safety in Saw Palmetto Extract Products

2024-07-04

1. Introduction

Saw Palmetto Extract has emerged as a highly popular ingredient in numerous health - related applications in recent years. Derived from the berries of the saw palmetto plant (Serenoa repens), it is widely used in supplements aimed at promoting prostate health, reducing hair loss, and even for its potential anti - inflammatory properties. However, as with any natural product used for medicinal or health - promoting purposes, ensuring the purity of Saw Palmetto Extract products is of utmost importance. This article will explore the various aspects of quality control, safety measures, and regulatory compliance associated with these products, highlighting their significance for consumer health.

2. Raw Material Sourcing

2.1 Geographic Origin

The geographic origin of the saw palmetto berries plays a crucial role in determining the quality of the extract. Berries sourced from different regions may vary in their chemical composition due to differences in soil quality, climate, and growing conditions. For example, berries grown in Florida, which is a major source of saw palmetto in the United States, may have different characteristics compared to those grown in other parts of the world. It is important for manufacturers to carefully select their sources to ensure consistency in the final product.

2.2 Sustainable Harvesting

Sustainable harvesting practices are essential to maintain the long - term availability of saw palmetto berries and protect the environment. Over - harvesting can lead to a decline in the plant population and disrupt the ecological balance. Manufacturers should work with suppliers who follow sustainable harvesting methods, such as limiting the amount of berries harvested per area and allowing the plants to regenerate. This not only ensures a continuous supply of raw materials but also contributes to the overall environmental sustainability.

2.3 Quality of Raw Berries

When sourcing raw saw palmetto berries, several factors related to their quality need to be considered. The berries should be free from contaminants such as pesticides, heavy metals, and microbial pathogens. Pesticide residues can be a significant concern, especially if the berries are grown using conventional farming methods. Manufacturers should require suppliers to provide certificates of analysis indicating that the berries meet strict safety standards for pesticide levels. Additionally, the berries should be harvested at the appropriate stage of ripeness to ensure optimal chemical composition. Berries that are over - ripe or under - ripe may not yield high - quality extract.

3. Manufacturing Process

3.1 Extraction Methods

There are several methods for extracting the active compounds from saw palmetto berries, and the choice of extraction method can significantly impact the purity and quality of the final product. Solvent extraction is one of the most common methods, but the type of solvent used is crucial. Some solvents may leave behind residues that could be harmful or may not effectively extract all the desired compounds. Ethanol is often considered a relatively safe and effective solvent for Saw Palmetto Extraction. However, manufacturers need to ensure that the ethanol is of high purity and that all solvent residues are removed during the purification process. Another extraction method is supercritical fluid extraction, which uses carbon dioxide under high - pressure and - temperature conditions. This method has the advantage of leaving no solvent residues and can produce a more pure extract, but it is also more expensive and requires specialized equipment.

3.2 Purification and Concentration

After extraction, the saw palmetto extract typically undergoes purification and concentration processes. Purification is necessary to remove any remaining impurities, such as unwanted plant materials, pigments, and other non - active components. Filtration, chromatography, and centrifugation are some of the techniques used for purification. Concentration, on the other hand, increases the potency of the extract by reducing the amount of solvent or water present. However, it is important to ensure that during these processes, the active compounds are not degraded or lost. Manufacturers need to closely monitor and control the parameters such as temperature, pressure, and time to maintain the integrity of the extract.

3.3 Quality Control During Manufacturing

Throughout the manufacturing process, strict quality control measures should be in place. This includes regular testing of the intermediate products and the final extract. Analytical methods such as high - performance liquid chromatography (HPLC) and gas chromatography - mass spectrometry (GC - MS) are used to determine the chemical composition of the extract, identify the presence of any impurities, and ensure that the concentration of the active compounds is within the specified range. In - process quality control also involves monitoring the manufacturing environment to prevent contamination. For example, the production facilities should be clean, and proper air filtration and sterilization procedures should be implemented.

4. Safety Measures

4.1 Potential Side Effects

While saw palmetto extract is generally considered safe for most people, it can have some potential side effects. These may include mild gastrointestinal symptoms such as nausea, diarrhea, and abdominal discomfort. In some cases, it may also interact with certain medications, such as blood - thinning drugs or hormones. It is important for manufacturers to include information about these potential side effects on the product labels to ensure that consumers are aware of the risks. Additionally, research is ongoing to further understand the long - term safety of saw palmetto extract, especially when used in high doses or for extended periods.

4.2 Allergen Control

Some individuals may be allergic to components in saw palmetto extract or to other substances that may be present as contaminants. Manufacturers need to take steps to control allergens during the manufacturing process. This includes ensuring that the raw materials are free from common allergens such as nuts, gluten, and dairy products if cross - contamination is a possibility. Additionally, proper labeling should be provided to indicate the presence of any potential allergens, even if they are present in trace amounts.

4.3 Packaging and Storage

The packaging and storage of saw palmetto extract products also play a role in ensuring safety and maintaining product quality. Light - sensitive and moisture - sensitive extracts should be packaged in appropriate containers that protect them from these environmental factors. For example, amber - colored glass bottles can be used to protect the extract from light, and desiccants can be added to the packaging to prevent moisture absorption. Storage conditions should also be carefully controlled. The products should be stored in a cool, dry place away from direct sunlight to prevent degradation of the active compounds.

5. Regulatory Compliance

5.1 FDA Regulations in the United States

In the United States, saw palmetto extract products are regulated as dietary supplements by the Food and Drug Administration (FDA). While dietary supplements are not subject to the same level of pre - market approval as drugs, they are still required to comply with certain regulations. Manufacturers are responsible for ensuring the safety of their products, and they must not make false or unsubstantiated claims about the health benefits of saw palmetto extract. The FDA also has guidelines regarding good manufacturing practices (GMP) for dietary supplements, which include requirements for quality control, record - keeping, and labeling. Failure to comply with these regulations can result in enforcement actions such as product recalls, warnings, or even legal penalties.

5.2 European Union Regulations

In the European Union, saw palmetto extract products are also subject to regulatory requirements. The EU has a more comprehensive regulatory framework for herbal products, which includes requirements for safety, quality, and efficacy evaluation. Herbal products must be registered or authorized before they can be marketed in the EU. This process involves submitting detailed information about the product, including its composition, manufacturing process, and safety data. Additionally, the EU has strict labeling requirements, which must include information about the ingredients, dosage, and any potential side effects or contraindications.

5.3 International Harmonization

There is an increasing trend towards international harmonization of regulations for herbal products, including saw palmetto extract. This is important to ensure that products can be traded globally and that consumers are protected regardless of where the products are sourced or sold. International organizations such as the World Health Organization (WHO) are working towards developing global guidelines for herbal medicine quality control and safety assessment. These efforts aim to standardize the requirements for raw material sourcing, manufacturing, and product labeling across different countries.

6. Impact on Consumer Health

6.1 Efficacy of Pure Products

Ensuring the purity of saw palmetto extract products is directly related to their efficacy. Pure products that are free from contaminants and have a consistent chemical composition are more likely to deliver the expected health benefits. For example, in the case of prostate health, pure saw palmetto extract may be more effective in reducing symptoms such as urinary frequency and improving overall prostate function. Consumers who use high - quality, pure products are more likely to experience positive results compared to those who use products of inferior quality.

6.2 Building Consumer Trust

When manufacturers adhere to strict quality and safety standards, it helps to build consumer trust. Consumers are more likely to choose products that they believe are safe and of high quality. This trust can have a significant impact on the success of saw palmetto extract products in the market. A positive reputation for quality and safety can lead to increased brand loyalty and repeat purchases, as well as positive word - of - mouth recommendations. On the other hand, incidents of product contamination or non - compliance with regulations can quickly damage a brand's reputation and lead to a loss of consumer confidence.

7. Conclusion

In conclusion, ensuring purity in saw palmetto extract products is a multi - faceted process that involves careful attention to raw material sourcing, manufacturing processes, safety measures, and regulatory compliance. From the selection of high - quality berries from sustainable sources to the use of appropriate extraction and purification methods, every step in the production chain is crucial. Safety measures such as allergen control, proper packaging, and storage are essential to protect consumer health. Regulatory compliance, both at the national and international levels, provides a framework for ensuring product quality and safety. The impact on consumer health is significant, as pure products are more likely to be effective and can build consumer trust. As the popularity of saw palmetto extract continues to grow, it is imperative that manufacturers maintain high standards to meet the expectations of consumers and contribute to the overall well - being of those who use these products.

FAQ:

What are the key steps in quality control for saw palmetto extract products?

The key steps in quality control for saw palmetto extract products include careful raw material sourcing. This involves selecting high - quality saw palmetto berries from reliable suppliers. During the manufacturing process, strict monitoring of extraction methods is necessary to ensure consistency and purity. Quality control also extends to testing for contaminants, such as heavy metals and pesticides, and verifying the correct concentration of active ingredients.

How does regulatory compliance affect the purity of saw palmetto extract products?

Regulatory compliance plays a significant role in ensuring the purity of saw palmetto extract products. Regulatory bodies set standards for manufacturing practices, ingredient quality, and product labeling. By adhering to these regulations, manufacturers are forced to follow strict guidelines that help maintain purity. For example, regulations may limit the amount of certain impurities allowed in the product, ensuring that consumers receive a safe and pure product.

What safety measures are typically implemented in the production of saw palmetto extract products?

In the production of saw palmetto extract products, several safety measures are typically implemented. Firstly, workers handling the raw materials and during the manufacturing process are required to follow safety protocols to prevent contamination. The production facilities are often maintained at specific environmental conditions to preserve the integrity of the extract. Additionally, strict quality control tests are carried out at various stages of production to detect any potential safety risks, such as microbial contamination or the presence of harmful substances.

Why is purity important for the consumer health in saw palmetto extract products?

Purity is crucial for consumer health in saw palmetto extract products because impure products may contain harmful substances. If the product is contaminated with heavy metals, pesticides, or other toxins, it can pose serious health risks. Moreover, an impure product may not have the correct concentration of active ingredients, which could lead to ineffective treatment or unexpected side effects. High - purity products are more likely to deliver the expected health benefits without causing harm.

How can consumers ensure they are purchasing pure saw palmetto extract products?

Consumers can take several steps to ensure they are purchasing pure saw palmetto extract products. They should look for products from reputable manufacturers with a history of quality production. Checking for third - party certifications, such as Good Manufacturing Practice (GMP) certification, can also be helpful. Reading product labels carefully to understand the ingredients and any purity claims is another important step. Additionally, consumers can research online reviews and consult with healthcare professionals for advice on reliable products.

Related literature

- Quality Control in Saw Palmetto Extract Production"

- "Safety Regulations for Herbal Extracts: A Focus on Saw Palmetto"

- "The Impact of Purity on the Efficacy of Saw Palmetto Extract in Health Applications"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Lycopene

2024-07-04

-

Tongkat Ali Extract

2024-07-04

-

Yohimbine Bark Extract

2024-07-04

-

Mulberry Extract

2024-07-04

-

melatonin extract

2024-07-04

-

Lavender Extract

2024-07-04

-

Quercetin

2024-07-04

-

Maca Extract

2024-07-04

-

Moringa powder

2024-07-04

-

Yellow Pine Extract

2024-07-04