- 0086-571-85302990

- sales@greenskybio.com

Chinese Diosmin Powder Factories.

2024-11-27

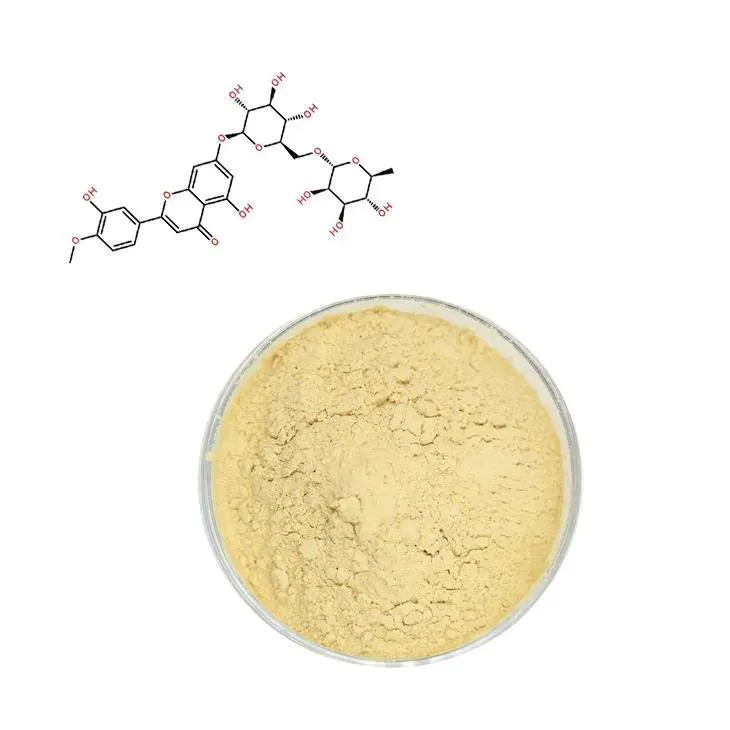

Introduction to Diosmin and Its Significance

Diosmin, a flavonoid glycoside, has been recognized for its remarkable properties, especially in relation to blood vessels and circulation. It plays a crucial role in maintaining the health of blood vessels by strengthening their walls, reducing inflammation, and improving venous tone. These beneficial effects have led to its extensive use in the pharmaceutical and nutraceutical industries. In China, the production of Diosmin powder has become a significant area of focus, with factories dedicated to manufacturing high - quality Diosmin for both domestic and international markets.

State - of - the - Art Facilities in Chinese Diosmin Powder Factories

The Diosmin powder factories in China are equipped with state - of - the - art facilities, which are essential for ensuring the high - quality production of Diosmin powder.

Advanced Extraction Equipment

One of the initial steps in Diosmin production is extraction. Chinese factories use advanced extraction equipment that is capable of efficiently extracting Diosmin from its natural sources. These extraction processes are carefully designed to maximize the yield of Diosmin while minimizing the extraction of unwanted compounds. For example, some factories use supercritical fluid extraction technology, which offers several advantages over traditional extraction methods. It allows for a more selective extraction, operates at relatively low temperatures to preserve the integrity of the Diosmin molecule, and is more environmentally friendly as it often uses non - toxic solvents.

Precision Purification Techniques

After extraction, the purification of Diosmin is of utmost importance. Chinese factories employ high - tech purification techniques such as advanced chromatography techniques. Chromatography, whether it is liquid chromatography or gas chromatography, depending on the nature of the sample, is used to separate and purify Diosmin from other substances present in the extract. This ensures that the final Diosmin powder has a high level of purity, free from contaminants and impurities that could affect its quality and efficacy. In addition to chromatography, other purification methods like crystallization may also be used in combination to further enhance the purity of the Diosmin powder.

High - Quality Powder Formation

Once the Diosmin has been purified, it needs to be converted into a powder form for easy handling, storage, and use. Chinese factories use specialized equipment for powder formation. This equipment is designed to produce Diosmin powder with the desired particle size distribution, which can influence its solubility and bioavailability. The powder formation process is carefully controlled to ensure that the Diosmin powder has consistent quality characteristics, such as flowability and compressibility, which are important for further formulation into pharmaceutical products or supplements.

Compliance with International Regulations

Chinese Diosmin powder factories place a great emphasis on compliance with international regulations, which is crucial for their success in the global market.

Adherence to GMP Guidelines

Good Manufacturing Practice (GMP) guidelines are strictly followed in these factories. GMP is a set of standards that ensure the quality, safety, and efficacy of pharmaceutical products. In the context of Diosmin powder production, this includes proper documentation of all production processes. Every step, from the sourcing of raw materials to the final packaging of the Diosmin powder, is meticulously recorded. This documentation not only helps in quality control but also allows for traceability in case of any issues. Additionally, strict personnel training is an integral part of GMP compliance. Factory workers are trained in proper handling procedures, hygiene practices, and quality control measures. Hygienic manufacturing environments are maintained to prevent contamination of the Diosmin powder. This includes regular cleaning and sanitization of production areas, proper ventilation, and control of environmental factors such as temperature and humidity.

Meeting International Quality Standards

Besides GMP, Chinese Diosmin powder factories also strive to meet other international quality standards. For example, they may adhere to standards set by regulatory bodies in different countries or regions. This ensures that their Diosmin powder can be exported and used in various international markets without any quality - related issues. These factories often participate in international quality audits and certifications to demonstrate their commitment to high - quality production. By meeting international quality standards, they are able to build trust with customers both at home and abroad and enhance their reputation in the global market.

Research and Innovation in Chinese Diosmin Powder Factories

Research and innovation are key drivers of success in Chinese Diosmin powder factories.

Enhancing Bioavailability

Scientists in these factories are constantly researching ways to enhance the bioavailability of Diosmin powder. Bioavailability refers to the proportion of a drug or supplement that enters the circulation and has an active effect. One approach could be through the development of novel formulations. For example, they may be exploring the use of nanotechnology to encapsulate Diosmin, which can improve its solubility and absorption in the body. Another area of research could be in modifying the chemical structure of Diosmin to make it more easily absorbed by the body. These efforts not only improve the effectiveness of Diosmin powder but also open up new opportunities for its application in different medical and nutraceutical products.

Novel Formulations Development

In addition to enhancing bioavailability, Chinese factories are also engaged in the development of novel formulations of Diosmin powder. This could include formulating Diosmin in combination with other active ingredients to create more effective products. For instance, combining Diosmin with vitamins or other flavonoids may result in synergistic effects, enhancing the overall health benefits. They may also be exploring different dosage forms such as tablets, capsules, or liquid formulations to meet the diverse needs of consumers. Novel formulations can also improve the stability of Diosmin powder, allowing for longer shelf - lives and better storage conditions.

Cost - Effectiveness of Production

The cost - effectiveness of production in Chinese Diosmin powder factories is a significant advantage.

Efficient Production Management

Chinese factories have implemented efficient production management systems. This includes optimizing the production process flow to reduce waste and increase productivity. Through careful planning and scheduling, they are able to ensure a continuous supply of raw materials and minimize production downtime. For example, they may use just - in - time inventory management systems to reduce inventory costs while still maintaining a reliable supply of raw materials. Additionally, quality control is integrated into the production process to catch any defects early, reducing the cost of rework or waste.

Economies of Scale

Another factor contributing to cost - effectiveness is economies of scale. The large - scale production of Diosmin powder in China allows factories to take advantage of lower unit costs. Bulk purchasing of raw materials often results in lower prices, and the spreading of fixed costs (such as equipment depreciation and facility maintenance) over a large volume of production reduces the cost per unit. This enables Chinese factories to offer high - quality Diosmin powder at competitive prices, making it more accessible to a wide range of customers both in the domestic and international markets.

Conclusion

Chinese Diosmin powder factories have emerged as leaders in the production of this important pharmaceutical ingredient. Their state - of - the - art facilities, compliance with international regulations, focus on research and innovation, and cost - effectiveness of production all contribute to their success. These factories not only play a vital role in supplying high - quality Diosmin powder for various applications but also contribute to the growth and competitiveness of the global Diosmin market. As research and technology continue to advance, it is expected that Chinese Diosmin powder factories will continue to innovate and improve, further strengthening their position in the international market.

FAQ:

What are the main features of Chinese Diosmin powder factories?

Chinese Diosmin powder factories are characterized by state - of - the - art facilities. They use high - tech equipment for extraction, purification, and powder formation. They also comply with international regulations like GMP guidelines, emphasize research and innovation, and have cost - effective production.

How do Chinese Diosmin powder factories ensure product quality?

They ensure product quality by adhering to strict GMP guidelines. This involves proper documentation of production processes, strict personnel training, and maintaining hygienic manufacturing environments. Advanced techniques like chromatography are used for purification.

What role does research play in Chinese Diosmin powder factories?

Research in these factories is crucial. Scientists are constantly looking for new ways to enhance the bioavailability of Diosmin powder and develop novel formulations. This helps in the medical field and also makes the factories more competitive globally.

Why are Chinese Diosmin powder factories cost - effective?

They are cost - effective due to efficient production management and economies of scale. This allows them to offer high - quality Diosmin powder at competitive prices, reaching a wider range of customers both domestically and internationally.

How do Chinese Diosmin powder factories purify Diosmin?

Often, advanced chromatography techniques are employed to separate and purify Diosmin from natural sources in these factories.

Related literature

- Diosmin Production: Modern Techniques and Quality Control"

- "The Role of Chinese Factories in Diosmin Powder Manufacturing"

- "Advances in Diosmin Powder Production in China"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

100% Pure Natural L - carnitine.

2024-11-27

-

Chinese Motherwort Extract Powder Factory.

2024-11-27

-

100% 纯有机葡萄籽提取物粉

2024-11-27

-

Manufacturers of Organic Diosmin Powder.

2024-11-27

-

Okra Extract

2024-11-27

-

Troxerutin

2024-11-27

-

White mustard seed extract

2024-11-27

-

Berberis aristata Extract

2024-11-27

-

Maca Extract

2024-11-27

-

Propolis Extract Powder

2024-11-27

-

Maitake Mushroom Extract

2024-11-27

-

Echinacea Extract

2024-11-27

-

Longan Extract

2024-11-27

-

Lavender Extract

2024-11-27