- 0086-571-85302990

- sales@greenskybio.com

Chinese Resveratrol Extract Factories.

2024-11-28

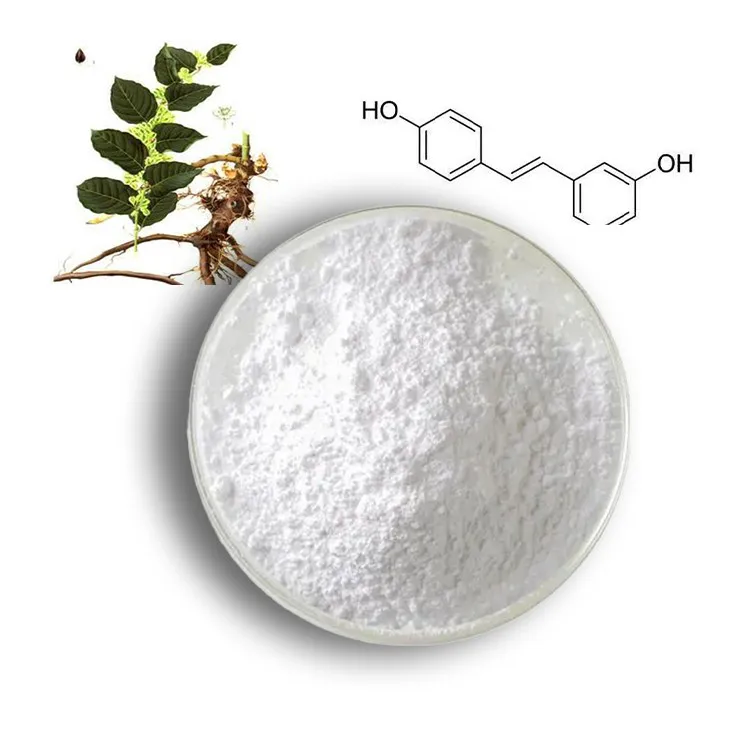

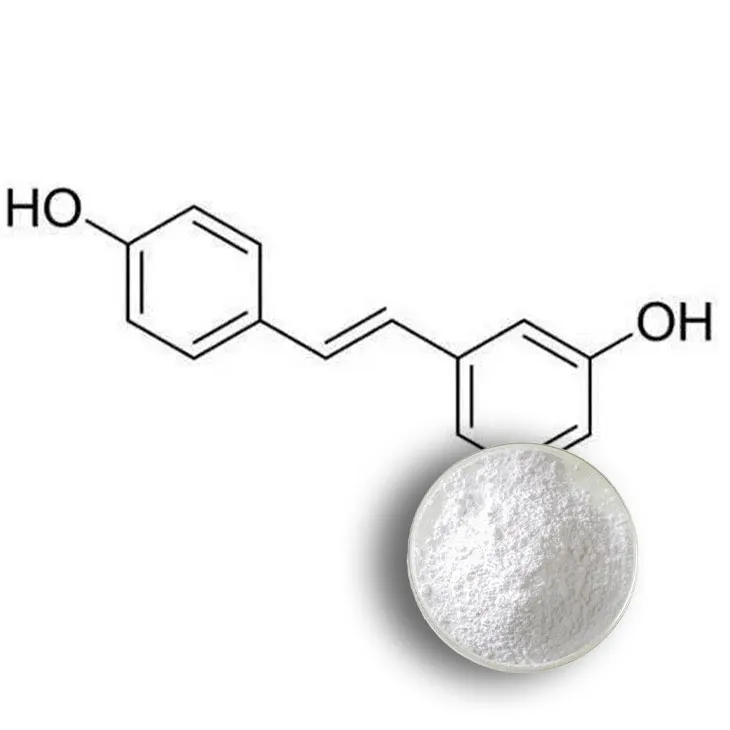

Introduction to Resveratrol

Resveratrol is a natural compound that has been the focus of much attention in recent years. It is found in various plants, including grapes, peanuts, and some berries. This compound is known for its potential health benefits, which has led to an increased demand for its extraction.

Role of Chinese Resveratrol extract Factories in the Production Chain

Chinese Resveratrol extract factories play a crucial role in the overall production chain.

Sourcing High - Quality Raw Materials

These factories are meticulous in sourcing their raw materials. They often utilize advanced agricultural techniques to ensure that the plants they use are rich in resveratrol. For instance:

- Some factories collaborate with local farmers to cultivate grapes specifically selected for high resveratrol content. This involves providing farmers with the knowledge and resources to grow grapes in the best possible conditions.

- They may also have strict criteria for the selection of peanuts and berries, ensuring that only the highest - quality produce is used as raw materials.

The Extraction Process in Chinese Factories

The extraction process in Chinese Resveratrol extract factories is a highly sophisticated one.

Initial Purification of Plant Materials

The process typically begins with the purification of the plant materials. This step is essential as it helps to remove any impurities that may be present in the raw materials.

- First, the plants are carefully washed to remove dirt, pesticides, and other contaminants.

- Then, they are dried under controlled conditions to preserve the integrity of the resveratrol within them.

Advanced Extraction Techniques

After the initial purification, the actual extraction of resveratrol takes place. Modern technologies are often employed to enhance the efficiency and purity of the extraction.

- One such technology is supercritical fluid extraction. This method uses a supercritical fluid, such as carbon dioxide, which has properties between those of a gas and a liquid. It can penetrate the plant material more effectively than traditional solvents and selectively extract resveratrol, resulting in a higher - purity product.

- Another technique that may be used is solvent extraction. However, this requires careful selection of solvents to ensure that they are safe and do not contaminate the final product.

Final Purification and Concentration

Once the resveratrol has been initially extracted, further purification and concentration steps are carried out.

- The extract is often passed through various filtration systems to remove any remaining impurities.

- Then, it may be concentrated to increase the resveratrol content, making it suitable for use in different industries.

Quality Control in Chinese Resveratrol Extract Factories

Quality control is of utmost importance in Chinese resveratrol extract factories. They must adhere to strict quality control standards to ensure the safety and suitability of their products.

Meeting Domestic and International Regulations

These factories have to meet both domestic and international regulations.

- Domestically, they need to comply with Chinese food and drug safety regulations. This includes ensuring that the extraction process is carried out in a hygienic environment and that the final product meets the required quality standards.

- Internationally, they may need to meet the standards of different countries where their products are exported. For example, in the United States, the product may need to meet the regulations set by the Food and Drug Administration (FDA), while in the European Union, it must adhere to EU regulations.

Testing for Purity and Safety

To ensure the quality of the resveratrol extract, extensive testing is carried out.

- Purity testing is done to determine the exact percentage of resveratrol in the extract. This is important as different applications may require different levels of purity.

- Safety testing includes tests for contaminants such as heavy metals, pesticides, and microbial contamination. Any presence of these contaminants above the allowed limits would render the product unfit for consumption or use in other industries.

Documentation and Traceability

Proper documentation and traceability are also important aspects of quality control.

- Factories keep detailed records of the entire production process, from the sourcing of raw materials to the final packaging of the product. This allows for easy traceability in case of any issues.

- Documentation also includes certificates of analysis for each batch of the product, which provide information about its quality and compliance with regulations.

Applications of Resveratrol Extract in Different Industries

Resveratrol extract produced by Chinese factories has a wide range of applications in different industries.

The Pharmaceutical Industry

In the pharmaceutical industry, resveratrol has shown potential in various areas.

- It has been studied for its antioxidant properties, which may help in preventing oxidative damage in cells. This could potentially be used in the development of drugs for diseases related to oxidative stress, such as certain neurodegenerative diseases.

- Resveratrol has also been investigated for its anti - inflammatory effects. Inflammation is a key factor in many diseases, and drugs with anti - inflammatory properties are in high demand. Resveratrol extract could potentially be used as an ingredient in such drugs.

The Cosmetic Industry

The cosmetic industry is another major user of resveratrol extract.

- Due to its antioxidant properties, resveratrol is used in anti - aging products. It can help to reduce the appearance of wrinkles and fine lines by protecting the skin from free radical damage.

- It may also have anti - inflammatory effects on the skin, which can be beneficial for treating skin conditions such as acne and eczema.

The Food Supplement Industry

Resveratrol extract is widely used in the food supplement industry.

- As a dietary supplement, it is often marketed for its potential health benefits, such as improving heart health, reducing the risk of certain cancers, and enhancing the immune system.

- It can be incorporated into various forms of supplements, including capsules, tablets, and powders.

Future Outlook for Chinese Resveratrol Extract Factories

The future looks promising for Chinese resveratrol extract factories, but there are also challenges ahead.

Opportunities for Growth

There are several opportunities for growth in the resveratrol extraction industry.

- The increasing awareness of the potential health benefits of resveratrol is likely to drive up the demand for its extract. This presents an opportunity for Chinese factories to expand their production capacity and market share.

- Advancements in extraction technology may further improve the efficiency and purity of resveratrol extraction, allowing factories to produce higher - quality products at a lower cost.

Challenges to Overcome

However, there are also challenges that Chinese resveratrol extract factories need to overcome.

- Competition from other countries in the global market is a significant challenge. Factories need to continuously improve their production processes and product quality to stay competitive.

- Meeting increasingly strict environmental regulations is also a concern. The extraction process may generate waste and emissions, and factories need to find ways to reduce their environmental impact.

FAQ:

What are the main raw materials for resveratrol extraction in Chinese factories?

Chinese resveratrol extract factories mainly use plants such as grapes, peanuts, and some berries as raw materials. These plants are known to contain resveratrol naturally. Some factories also collaborate with local farmers to cultivate specific varieties of these plants, like grapes selected for high resveratrol content.

What is the extraction process in Chinese resveratrol extract factories?

The extraction process in these factories is complex and typically involves multiple steps. It starts from purifying the plant materials. Then, modern technologies like supercritical fluid extraction may be used to finally extract pure resveratrol. This process aims to enhance the efficiency and purity of the extraction.

How do Chinese resveratrol extract factories ensure product quality?

These factories adhere to strict quality control standards. They need to meet both domestic and international regulations. This ensures that the final product is safe for consumption and suitable for use in various industries, including the pharmaceutical, cosmetic, and food supplement industries.

Why are there many resveratrol extract factories in China?

China has a large number of resveratrol extract factories due to several reasons. Firstly, there is an abundance of raw materials in China as many plants containing resveratrol can be grown here. Secondly, there is a growing global demand for resveratrol - based products because of its potential health benefits, which has led to the establishment of more factories in China to meet this demand.

What industries use the resveratrol extract from Chinese factories?

The resveratrol extract from Chinese factories is used in several industries. The pharmaceutical industry may use it for potential medicinal properties. The cosmetic industry can use it in products for its antioxidant properties. Also, the food supplement industry uses it as it is believed to have various health - promoting effects.

Related literature

- Resveratrol: Sources, Extraction, and Health Benefits"

- "The Role of Chinese Factories in Resveratrol Production and Its Global Impact"

- "Advanced Extraction Techniques in Chinese Resveratrol Factories"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

Organic Saw Palmetto Extract Powder Factory.

2024-11-28

-

Suppliers of Organic Açai Extract Powder.

2024-11-28

-

Extraction process of black pepper extract.

2024-11-28

-

Wholesale L - Tyrosine Suppliers.

2024-11-28

-

The best milk thistle extract in 2024.

2024-11-28

-

High - quality kidney bean extract products.

2024-11-28

-

The best aged garlic extract on the market.

2024-11-28

-

Kidney Bean Extract

2024-11-28

-

Hericium erinaceus extract powder

2024-11-28

-

Alfalfa Meal

2024-11-28

-

Dan Shen Root Extract/Salvia Root Extract

2024-11-28

-

Chia Seed Powder

2024-11-28

-

Acerola Extract

2024-11-28

-

Sophora Japonica Flower Extract

2024-11-28

-

Red Wine Extract

2024-11-28

-

Thunder God Vine Extract

2024-11-28

-

Citrus bioflavonoids

2024-11-28