- 0086-571-85302990

- sales@greenskybio.com

Extract Eucommia ulmoides extracts by steam distillation.

2024-11-29

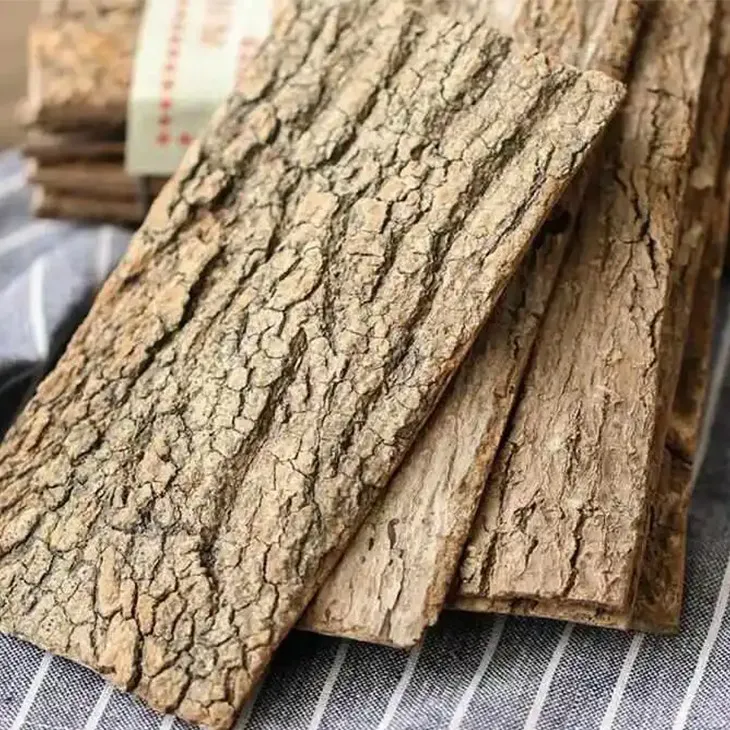

1. Introduction to Eucommia ulmoides

Eucommia ulmoides, a deciduous tree native to China, has been highly regarded for its numerous potential applications. It has a long history of use in traditional Chinese medicine and is now attracting increasing attention in modern fields such as nutraceuticals and cosmeceuticals. The plant contains a variety of bioactive components, which are the key to its diverse functions. These components include flavonoids, lignans, and terpenoids, among others. These natural substances endow Eucommia ulmoides with properties such as antioxidant, anti - inflammatory, and hypotensive effects.

2. Why Steam Distillation?

Steam distillation is a popular method for extracting valuable components from plants like Eucommia ulmoides. There are several reasons for this choice.

- Firstly, it is a relatively mild extraction method. It can extract volatile components without causing excessive degradation of the active substances. This is crucial for maintaining the bioactivity of the extract.

- Secondly, steam distillation can separate the desired components from the complex matrix of the plant material effectively. It works based on the different volatilities of the components in the plant. The volatile components will vaporize along with the steam and can be collected and condensed separately.

- Finally, it is a well - established and cost - effective method in the industry. The equipment required for steam distillation is relatively simple and widely available, making it suitable for both small - scale laboratory extractions and large - scale industrial production.

3. The Steam Distillation Apparatus

A typical steam distillation apparatus for Eucommia Ulmoides Extraction consists of several key components.

- The distillation flask is where the plant material (Eucommia ulmoides) is placed. It should be of an appropriate size depending on the amount of plant material to be processed. For small - scale extractions in the laboratory, a flask with a capacity of 500 ml to 1000 ml may be sufficient. For industrial - scale operations, much larger flasks or even specialized reactors are used.

- The steam generator is responsible for producing steam. This can be a simple device such as a steam - generating kettle. In industrial settings, more powerful and continuous steam - generating systems are employed to ensure a stable supply of steam throughout the extraction process.

- The condenser is used to cool down the vapor mixture of steam and volatile components from the distillation flask. There are different types of condensers, such as water - cooled condensers. The cooled vapor then condenses back into a liquid state, which is the crude extract.

- The receiver is the final component where the condensed extract is collected. It should be clean and properly sealed to prevent contamination and evaporation of the extract.

4. Operating Conditions

The proper operation of steam distillation for Eucommia Ulmoides Extraction depends on several key operating conditions.

- Temperature: The temperature is an important factor. In general, the steam temperature should be maintained at a suitable level. For Eucommia ulmoides, a steam temperature of around 100 - 120 °C is often used. If the temperature is too low, the extraction efficiency may be low as the volatile components may not vaporize completely. On the other hand, if the temperature is too high, it may cause some thermal degradation of the active components.

- Pressure: Maintaining the appropriate pressure is also crucial. In most cases, the steam distillation is carried out at normal atmospheric pressure. However, in some industrial applications, slightly elevated or reduced pressure may be used to optimize the extraction process. For example, a slightly reduced pressure can help to lower the boiling point of the components, which may be beneficial for some heat - sensitive components.

- Extraction time: The extraction time needs to be carefully determined. A typical extraction time for Eucommia ulmoides may range from 2 - 6 hours. A shorter extraction time may result in incomplete extraction of the valuable components, while an overly long extraction time may not necessarily increase the yield significantly and may even introduce impurities.

5. Factors Affecting the Extraction Yield

Several factors can influence the extraction yield of Eucommia ulmoides by steam distillation.

- Particle size of the plant material: The size of the Eucommia ulmoides particles affects the extraction efficiency. Finer particles generally have a larger surface area exposed to the steam, which can enhance the mass transfer between the plant material and the steam. However, if the particles are too fine, they may cause clogging in the distillation apparatus. A suitable particle size range is usually between 1 - 5 mm.

- Ratio of plant material to water: The ratio of Eucommia ulmoides to water in the distillation flask also plays a role. A proper ratio can ensure sufficient steam generation and good contact between the steam and the plant material. A common ratio is 1:5 - 1:10 (plant material: water).

- Quality of the plant material: The quality of the Eucommia ulmoides used for extraction is crucial. High - quality plant material with a high content of active components will naturally yield a higher amount of valuable extract. Factors such as the origin, growth conditions, and harvesting time of the plant can all affect its quality.

6. Quality and Bioactivity of the Extract

The quality and bioactivity of the Eucommia Ulmoides Extract obtained by steam distillation are of utmost importance.

- Quality assessment: The quality of the extract can be evaluated in terms of its chemical composition, purity, and physical properties. Analytical techniques such as high - performance liquid chromatography (HPLC) can be used to determine the content of key components such as flavonoids and lignans. Purity can be assessed by detecting the presence of impurities, such as residual solvents or non - target plant components.

- Bioactivity: The bioactivity of the extract is related to its potential health benefits. As mentioned earlier, Eucommia ulmoides extract has antioxidant, anti - inflammatory, and hypotensive properties. These bioactivities can be tested in vitro using cell - based assays or in vivo using animal models. For example, antioxidant activity can be measured by methods such as the DPPH (2,2 - diphenyl - 1 - picrylhydrazyl) free radical scavenging assay.

7. Applications of Eucommia ulmoides Extract

The Eucommia ulmoides extract obtained by steam distillation has a wide range of applications.

- In traditional medicine: It has been used for centuries in traditional Chinese medicine to treat various ailments, such as back pain, joint problems, and kidney deficiency. The extract is often formulated into herbal remedies, either as a single - ingredient preparation or in combination with other herbs.

- In nutraceuticals: In modern nutraceuticals, Eucommia ulmoides extract is added to dietary supplements due to its potential health - promoting properties. It can be found in products such as capsules, tablets, and functional drinks, targeting consumers interested in natural health products.

- In cosmeceuticals: The antioxidant and anti - inflammatory properties of the extract make it suitable for use in cosmeceutical products. It can be incorporated into creams, lotions, and serums to help improve skin health, reduce wrinkles, and soothe irritated skin.

8. Conclusion

Steam distillation is a valuable method for extracting Eucommia ulmoides extract. Understanding the plant's characteristics, the distillation apparatus, operating conditions, factors affecting extraction yield, and the quality and bioactivity of the extract is essential for obtaining a high - quality product. With its wide range of applications in traditional medicine, nutraceuticals, and cosmeceuticals, further research and optimization of the steam distillation process for Eucommia ulmoides extraction are warranted to fully realize its potential.

FAQ:

1. What are the natural characteristics of Eucommia ulmoides that make it suitable for steam distillation?

Eucommia ulmoides contains various volatile components. These volatile substances can be effectively separated by steam distillation. The plant has a certain chemical composition that is stable under the conditions of steam distillation and can release the desired extract components through the interaction with steam.

2. What are the main components of the distillation apparatus used for Eucommia ulmoides steam distillation?

The distillation apparatus usually consists of a steam generator, a distillation flask where the Eucommia ulmoides sample is placed, a condenser for cooling the vapor, and a collection vessel. The steam generator provides the steam which passes through the sample in the distillation flask. The condenser then cools the vaporized components so that they can be collected in the collection vessel.

3. How do operating conditions affect the steam distillation of Eucommia ulmoides?

Operating conditions such as temperature, pressure, and distillation time play crucial roles. Higher temperature can increase the vaporization rate of the components but may also cause degradation if too high. Appropriate pressure helps in maintaining a stable distillation process. Longer distillation time may increase the yield up to a certain point, but after that, it may lead to the extraction of unwanted substances or degradation of the desired components.

4. What factors can influence the extraction yield in Eucommia ulmoides steam distillation?

The particle size of the Eucommia ulmoides sample is an important factor. Smaller particle size generally provides a larger surface area for steam to interact with, potentially increasing the yield. The freshness and quality of the plant material also matter. High - quality and fresh samples are more likely to yield a greater amount of the desired extract. Additionally, the ratio of the plant material to the steam volume can impact the extraction yield.

5. How is the quality of the Eucommia ulmoides extract related to steam distillation?

Proper steam distillation is crucial for maintaining the quality of the extract. If the distillation conditions are not well - controlled, it can lead to the degradation of active components or the inclusion of impurities. The correct temperature, pressure, and time ensure that the bioactive components are effectively extracted while minimizing the extraction of non - useful or harmful substances, thus ensuring the high quality of the final extract.

6. How is the bioactivity of the Eucommia ulmoides extract determined?

The bioactivity of the extract can be determined through various in vitro and in vivo assays. In vitro assays may include tests on cell lines to observe effects such as antioxidant activity, anti - inflammatory activity, etc. In vivo assays involve using animal models to study the effects of the extract on physiological functions, such as its impact on blood pressure regulation or immune system enhancement.

Related literature

- Steam Distillation of Eucommia ulmoides: Optimization of Process Parameters"

- "The Bioactive Components of Eucommia ulmoides Extracts Obtained by Steam Distillation"

- "Quality Assessment of Eucommia ulmoides Extracts from Steam Distillation"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

The Best Rosemary Extract in 2024.

2024-11-29

-

The best - quality feverfew extract.

2024-11-29

-

The best organic aged garlic extract.

2024-11-29

-

Konjac flour manufacturers from China.

2024-11-29

-

Certified organic comfrey extract.

2024-11-29

-

The best sophora japonica extract in 2024.

2024-11-29

-

Black Rice Extract Manufacturers from China.

2024-11-29

-

Nature's Bounty Rhodiola Root Extract.

2024-11-29

-

Peppermint oil manufacturers from China.

2024-11-29

-

Citrus bioflavonoids

2024-11-29

-

Cat Claw Extract

2024-11-29

-

Maitake Mushroom Extract

2024-11-29

-

Hesperidin

2024-11-29

-

Hops Extract

2024-11-29

-

Fig Extract

2024-11-29

-

Moringa powder

2024-11-29

-

Longan Extract

2024-11-29

-

Hawthorn Extract

2024-11-29

-

Hedyotis Diffusa Extract

2024-11-29