- 0086-571-85302990

- sales@greenskybio.com

Preparation process of Eucommia ulmoides extracts.

2024-12-13

1. Introduction

Eucommia ulmoides is a valuable plant with various bioactive components. The extracts of Eucommia ulmoides have wide applications in medicine, health products, and cosmetics. Therefore, the preparation process of its extracts is of great significance.

2. Raw Material Selection

The first step in the preparation of Eucommia Ulmoides Extract is the careful selection of raw materials.

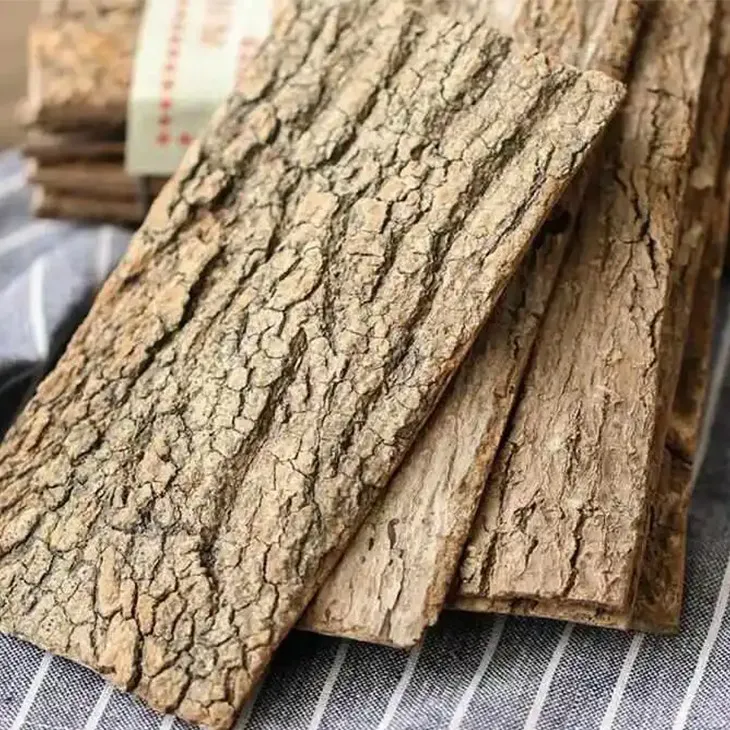

2.1 Quality of Eucommia ulmoides Bark

Usually, high - quality Eucommia ulmoides bark is chosen as the raw material. The quality of the bark can affect the content and quality of active substances in the final extract. For example, the bark should be free from diseases, pests, and excessive damage. A healthy and intact bark is more likely to contain a high amount of flavonoids, lignans and other valuable components.

2.2 Source and Collection

The source of Eucommia ulmoides also matters. It is preferably sourced from areas with suitable growth conditions, such as appropriate climate, soil, and altitude. When collecting the bark, proper methods should be used to ensure that the collection process does not cause unnecessary damage to the plant and its surrounding environment. For instance, in some cases, only a certain proportion of the bark can be collected from each tree to ensure the sustainable growth of Eucommia ulmoides.

3. Extraction Methods

There are several extraction methods for obtaining Eucommia Ulmoides Extracts, and each method has its own characteristics.

3.1 Solvent Extraction

- Solvent Selection: Different solvents can be used for solvent extraction. Ethanol is one of the commonly used solvents. Ethanol has good solubility for many active components in Eucommia ulmoides, such as flavonoids and lignans. It can effectively dissolve these substances from the raw materials.

- Extraction Process: In the extraction process, the Eucommia ulmoides bark is usually ground into a suitable particle size first. Then, it is mixed with the solvent at a certain ratio. For example, a common ratio could be 1:5 - 1:10 (bark:solvent by weight). The mixture is then placed in an extraction device, such as a Soxhlet extractor or a shaking flask. In the Soxhlet extractor, the solvent is continuously refluxed to ensure thorough extraction. In a shaking flask, the mixture is shaken at a certain speed and temperature for a period of time, usually several hours to days depending on the specific requirements.

3.2 Supercritical Fluid Extraction

- Principle: Supercritical fluid extraction is an advanced extraction technique. Supercritical fluids, such as supercritical carbon dioxide, have unique properties. They have the diffusivity of gases and the solubility of liquids. When carbon dioxide is in a supercritical state, it can selectively dissolve the target components in Eucommia ulmoides. This method has the advantages of high extraction efficiency, no solvent residue, and environmental - friendliness.

- Operation: In the operation process, the pressure and temperature need to be precisely controlled to maintain the supercritical state of the fluid. The Eucommia ulmoides raw materials are placed in the extraction chamber, and the supercritical fluid is passed through. After extraction, the pressure is reduced to separate the extract from the supercritical fluid. This process requires specialized equipment and strict operating conditions.

4. Purification Steps

After extraction, purification is necessary to remove impurities and obtain a high - quality Eucommia Ulmoides Extract.

4.1 Filtration

Filtration is a simple and commonly used purification method. The extract obtained after extraction usually contains solid particles such as plant debris. Using a filter, such as a filter paper or a membrane filter, these solid particles can be removed. For example, a filter paper with a suitable pore size can be used in a simple laboratory filtration. In industrial production, membrane filters with different pore sizes can be selected according to the specific requirements to ensure the clarity of the extract.

4.2 Centrifugation

Centrifugation is another effective purification method. By using a centrifuge, the extract is rotated at a high speed. Under the action of centrifugal force, the heavier impurities are separated from the extract and deposited at the bottom of the centrifuge tube or container. Different centrifuge speeds and times can be selected according to the nature of the extract and the amount of impurities. For example, for a relatively viscous extract, a higher centrifuge speed and longer time may be required.

5. Quality Control

Quality control is crucial throughout the preparation process of Eucommia ulmoides extract.

5.1 Component Analysis

- Flavonoids and Lignans Detection: Flavonoids and lignans are important active components in Eucommia ulmoides extract. High - performance liquid chromatography (HPLC) is often used to detect and quantify these components. HPLC can accurately separate and measure the content of different flavonoids and lignans in the extract, ensuring that the final product meets the expected quality standards.

- Other Components: In addition to flavonoids and lignans, other components in the extract may also need to be analyzed, such as polysaccharides, amino acids, etc. Different analytical methods are used according to the characteristics of these components to comprehensively evaluate the quality of the extract.

5.2 Purity and Safety Evaluation

- Purity: The purity of the extract is also an important index. It is necessary to ensure that there are no excessive impurities in the extract, which may affect its application effect. Methods such as total solids determination can be used to evaluate the purity of the extract.

- Safety: Safety evaluation is essential, especially when the extract is used in medicine and health products. Toxicological tests, such as acute toxicity tests and mutagenicity tests, are carried out to ensure that the extract is safe for human use.

6. Conclusion

The preparation process of Eucommia ulmoides extract is a complex but important process. From raw material selection to extraction, purification, and quality control, each step plays a crucial role in obtaining a high - quality extract with high - content active substances. With the continuous development of technology, more advanced extraction and purification methods may be explored in the future to further improve the quality and application value of Eucommia ulmoides extract.

FAQ:

Question 1: Why is high - quality Eucommia ulmoides bark chosen as the raw material?

High - quality Eucommia ulmoides bark is chosen because it contains a relatively high content of active components such as flavonoids and lignans. These active components are of great value for applications in medicine, health products and cosmetics, so high - quality bark can ensure a better quality of the final Eucommia ulmoides extract.

Question 2: What are the advantages of using ethanol in solvent extraction?

Ethanol is a commonly used solvent in the extraction of Eucommia ulmoides. One of its main advantages is its relatively good solubility for many active components in Eucommia ulmoides. It can effectively dissolve flavonoids, lignans and other substances. Also, ethanol is relatively safe, easy to obtain and has a relatively low toxicity compared to some other solvents, which makes it suitable for the extraction process.

Question 3: How does filtration work in the purification process?

Filtration in the purification process of Eucommia ulmoides extract works by passing the extract through a filter medium. The filter medium has pores of a certain size. Impurities with larger particle sizes are trapped on the filter, while the liquid containing the active components of Eucommia ulmoides can pass through, thus separating the impurities from the extract to a certain extent.

Question 4: What is the principle of supercritical fluid extraction?

Supercritical fluid extraction uses a supercritical fluid as the solvent. A supercritical fluid has properties between a gas and a liquid. For example, carbon dioxide in a supercritical state can penetrate into the matrix of Eucommia ulmoides more easily. It can selectively dissolve the target active components. By adjusting the pressure and temperature, the solubility of the supercritical fluid can be controlled, which helps to extract the active substances more efficiently and with higher purity compared to traditional extraction methods.

Question 5: What are the main applications of Eucommia ulmoides extract in medicine?

Eucommia ulmoides extract has several applications in medicine. It may have antioxidant properties due to its flavonoid content, which can help in preventing oxidative damage in the body. It may also have anti - inflammatory effects, potentially being useful in treating certain inflammatory diseases. Additionally, some studies suggest that it may have a role in improving cardiovascular health, for example, by regulating blood pressure and lipid metabolism.

Question 6: How can the quality of Eucommia ulmoides extract be ensured?

The quality of Eucommia ulmoides extract can be ensured through several means. Firstly, starting with high - quality raw materials as mentioned before. During the extraction process, using appropriate extraction methods and optimizing the extraction parameters such as solvent concentration, extraction time and temperature. In the purification steps, efficient removal of impurities through methods like filtration and centrifugation. Also, strict quality control tests should be carried out, such as analyzing the content of active components like flavonoids and lignans to ensure that they meet the required standards.

Related literature

- Studies on the Bioactive Components of Eucommia ulmoides Extracts"

- "Optimization of the Extraction Process of Eucommia ulmoides for High - Quality Extracts"

- "The Pharmacological Activities of Eucommia ulmoides Extract in Modern Medicine"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Pure 85% Tomentil Extract.

2024-12-13

-

Reishi mushroom extract

2024-12-13

-

Hedyotis Diffusa Extract

2024-12-13

-

Alfalfa Meal

2024-12-13

-

Garcinia Cambogia Extract

2024-12-13

-

Avocado Extract Powder

2024-12-13

-

Lycopene

2024-12-13

-

Boswellia Serrata Extract

2024-12-13

-

Ivy Extract

2024-12-13

-

Citrus bioflavonoids

2024-12-13

-

Aminolevulinic acid

2024-12-13